EPDM Waterproof Membrane for Roof and Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

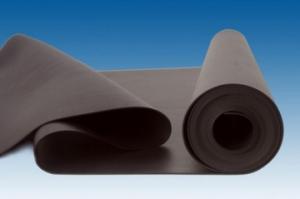

EPDM Rubber Waterproof Membrane Description:

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-

popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof

membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization

technology.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Systems

Thanks to a variety of installation systems, the RubberGard EPDM Roofing System provides a solution for even the most challenging rooftops, for both renovation and new built applications.

Products

The RubberGard EPDM Roofing System consists of a high performing EPDM and a complete range of accessories. The combination proven technology offers a unique combination of features & benefits.Technical Information

CNBM Products provides to distributors, contractors, specifiers and building owners a comprehensive range of technical documents, such as specifications, data sheets, type approvals and detail drawings.Installation

It help the contractor installing the RubberGard EPDM Roofing System in accordance with requirements.Training

The RubberGard EPDM Roofing System is exclusively installed by approved roofing contractors that have successfully completed a training program in one of training centers.EPDM Project References

Operating since 3 decades in Europe and Asia, our Products has installed hundreds of thousands of EPDM roofs. The project portfolio includes a selection of major projects.

Images of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen

waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof

Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be installed on vertical surfaces without causing sagging or drooping?

- Installing a waterproofing membrane on vertical surfaces without causing sagging or drooping is possible. The key lies in ensuring proper installation techniques and the use of suitable materials. To begin with, it is crucial to choose a high-quality waterproofing membrane designed specifically for vertical applications. These membranes are typically more rigid and offer better adhesion properties, enabling them to firmly adhere to vertical surfaces without sagging. Next, surface preparation plays a vital role in establishing a strong bond between the membrane and the vertical surface. It is important to thoroughly clean the surface, removing any debris, and properly prime it before applying the membrane. This step creates a solid foundation for the membrane and prevents any potential sagging or drooping. In addition, it is essential to follow proper installation techniques. Applying the membrane smoothly and evenly, without excessive stretching or folding, is key to avoiding sagging. Moreover, any seams or overlaps in the membrane should be carefully sealed to maintain a watertight barrier. Furthermore, it is recommended to use mechanical fixings like screws or nails to secure the membrane in place. These fixings provide additional support and help prevent sagging over time. In conclusion, by selecting the right materials, properly preparing the surface, and employing careful installation techniques, it is possible to install a waterproofing membrane on vertical surfaces without causing sagging or drooping.

- Q: Can a waterproofing membrane be used on terrazzo surfaces?

- Yes, a waterproofing membrane can be used on terrazzo surfaces. Terrazzo is a durable and long-lasting material, but it is porous and can absorb water if left untreated. Applying a waterproofing membrane helps protect the terrazzo surface from moisture damage, preventing water penetration and potential issues such as staining, cracking, or mold growth.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Yes, a waterproofing membrane can be applied to horizontal surfaces. In fact, it is commonly used to protect and waterproof horizontal surfaces such as roofs, decks, balconies, and other flat areas. The membrane acts as a barrier, preventing water from penetrating the surface and causing damage. It is typically made of a flexible material, such as rubber or modified bitumen, which can easily conform to the contours of the horizontal surface. Additionally, the membrane is designed to withstand foot traffic and other loads, ensuring long-lasting protection. Overall, applying a waterproofing membrane to horizontal surfaces is an effective way to prevent water damage and extend the lifespan of the surface.

- Q: Is a waterproofing membrane breathable?

- No, a waterproofing membrane is generally not breathable as its primary purpose is to prevent water from passing through.

- Q: Can a waterproofing membrane be used for power plants?

- Yes, a waterproofing membrane can be used for power plants. Waterproofing membranes are commonly used in various applications where water penetration needs to be prevented, and power plants are no exception. Power plants often have areas that are exposed to water, such as cooling towers, wet flue gas desulfurization systems, and other water management systems. Using a waterproofing membrane in these areas can help protect the structures and equipment from water damage, corrosion, and leaks. Additionally, waterproofing membranes can also be used in underground structures, such as basements or tunnels, which are commonly found in power plants. These membranes provide an effective barrier against water infiltration, ensuring the integrity and longevity of the structures in power plants. Therefore, utilizing a waterproofing membrane is a practical and beneficial solution for maintaining the performance and reliability of power plant facilities.

- Q: Can a waterproofing membrane be used in conjunction with sustainable construction materials?

- Indeed, the use of a waterproofing membrane alongside sustainable construction materials is gaining traction in the construction industry. This is due to the growing emphasis on environmentally friendly and energy-efficient buildings. Waterproofing membranes serve to safeguard sustainable construction materials, such as recycled or low-impact materials, against water damage and moisture infiltration. By forming a barrier, these membranes prevent water from permeating the materials, thereby extending their lifespan and reducing the necessity for repairs or replacements. Furthermore, sustainable construction materials are often engineered to enhance energy efficiency, which can be further augmented through the employment of a waterproofing membrane. By averting water damage, the membrane upholds the structural integrity of the building envelope, curbing potential energy loss from leaks or moisture intrusion. In addition, specific waterproofing membranes are designed with sustainability in mind. For instance, there are eco-friendly membranes fabricated from recycled materials or those that can be recycled at the end of their life cycle. These sustainable membranes minimize the environmental impact associated with their production and disposal. In conclusion, the integration of a waterproofing membrane in conjunction with sustainable construction materials is a wise and conscientious approach to building design. It ensures the long-term durability and performance of the materials, while also contributing to a more sustainable and energy-efficient built environment.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration, regardless of whether it is applied to the inside or outside of a structure.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Can a waterproofing membrane be used for solar panel installations?

- Yes, a waterproofing membrane can be used for solar panel installations. In fact, it is often recommended to use a waterproofing membrane as part of the installation process to protect the roof or other surfaces beneath the solar panels from water damage. A waterproofing membrane acts as a barrier to prevent water from seeping into the underlying structure, ensuring that the solar panel installation remains watertight and secure. This is particularly important as solar panels are typically installed on rooftops, where they are exposed to various weather conditions. By incorporating a waterproofing membrane, it helps to prolong the lifespan of the solar panels and prevents any potential water-related issues that could affect their performance.

- Q: Can a waterproofing membrane be used in showers and wet areas?

- Yes, a waterproofing membrane can be used in showers and wet areas. Waterproofing membranes are designed to provide a protective barrier against water penetration, making them ideal for use in areas that are constantly exposed to water, such as showers and wet areas.

Send your message to us

EPDM Waterproof Membrane for Roof and Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords