EPDM Coiled Rubber Waterproof Membrane/waterproofing membrane/lastomeric waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

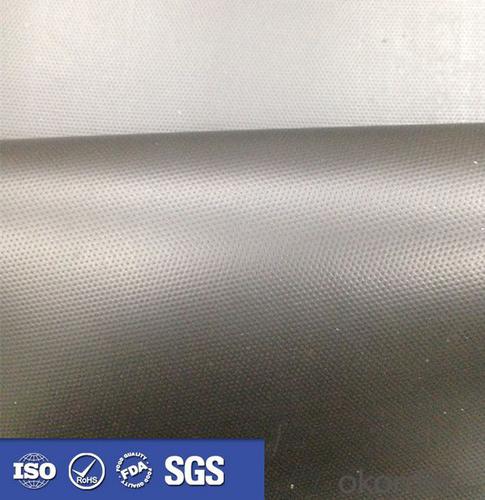

Description Of EPDM Coiled Rubber Waterproof Membrane:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Coiled Rubber Waterproof Membrane:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Coiled Rubber Waterproof Membrane:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Coiled Rubber Waterproof Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on plastic surfaces?

- Yes, a waterproofing membrane can be used on plastic surfaces.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Yes, a waterproofing membrane can be used on tunnels with architectural features. The membrane can be applied to various surfaces, including those with architectural features, to provide effective waterproofing and prevent water infiltration. This ensures the protection of the tunnel structure and helps maintain its integrity.

- Q: Can a waterproofing membrane be used for underground parking garages?

- Yes, a waterproofing membrane can be used effectively for underground parking garages. These membranes are specifically designed to provide a protective barrier against water infiltration, preventing damage to the structure and ensuring a dry and safe environment for vehicles.

- Q: Do you know how many square meters of waterproofing membrane to send a set of tests?

- Modified asphalt polyethylene tire waterproofing membrane: any volume in the distance 2m at the end of the interception of 1m full-width coil sample 2, 1000 volumes for a group, the lack of a group also

- Q: Can a waterproofing membrane be used on drywall surfaces?

- Yes, a waterproofing membrane can be used on drywall surfaces. Drywall is a porous material that can be susceptible to moisture damage, especially in areas prone to high humidity or water exposure, such as bathrooms or basements. Applying a waterproofing membrane on drywall helps create a barrier against moisture, preventing water infiltration and potential damage. This membrane can be in the form of a liquid coating or a sheet membrane that is applied directly onto the drywall surface. It is important to follow the manufacturer's instructions and ensure proper installation to achieve effective waterproofing and protect the drywall from moisture-related issues like mold, mildew, and rot.

- Q: Can a waterproofing membrane be used on swimming pools?

- Yes, a waterproofing membrane can be used on swimming pools. Waterproofing membranes are commonly used in the construction and maintenance of swimming pools to prevent water leakage and seepage. These membranes act as a barrier, ensuring that the pool remains watertight and preventing any water damage to the surrounding structures.

- Q: Can a waterproofing membrane be installed under tile or other flooring materials?

- Yes, a waterproofing membrane can be installed under tile or other flooring materials. Waterproofing membranes are commonly used in areas where moisture may be present, such as bathrooms, kitchens, and basements. These membranes act as a barrier, preventing water from seeping through the floor and causing damage to the underlying structure. They are typically applied directly onto the substrate before the tile or flooring material is installed. This ensures that any water or moisture that may penetrate the flooring is redirected and prevented from reaching the subfloor. By installing a waterproofing membrane, you can protect your floors and extend their lifespan while ensuring a dry and moisture-free environment.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Specific cleaning methods are required for a waterproofing membrane. To maintain its effectiveness and longevity, regular cleaning is important. The type of membrane being used will determine the specific cleaning methods, as different materials may have different requirements. It is generally advised to use gentle cleaning solutions and tools, such as a soft brush and mild detergent, to clean the membrane. Avoiding harsh chemicals or abrasive materials that could cause damage is crucial. Furthermore, regularly inspecting the membrane for signs of damage or debris buildup is essential. Addressing these issues promptly can prevent further damage and ensure continued effective waterproofing. It is highly recommended to consult the manufacturer's guidelines and recommendations for proper care and maintenance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for museums or art galleries?

- Museums or art galleries can benefit from the use of a waterproofing membrane. This membrane is commonly utilized across different industries, such as construction, to safeguard buildings against water damage. In the case of museums or art galleries, where valuable artifacts or artwork are stored, it is essential to maintain a controlled environment to prevent any water-related issues, such as leaks, moisture, or humidity. To create a barrier against water intrusion, a waterproofing membrane can be applied to the walls, floors, or even roofs of these establishments. Its purpose is to stop water from seeping through the building structure, protecting the artwork from potential harm. Furthermore, a waterproofing membrane can assist in regulating the humidity levels within the museum or art gallery. By minimizing moisture penetration, it helps to maintain a stable environment, which is crucial for preserving delicate artwork or artifacts that are sensitive to changes in humidity. Moreover, there are various types of waterproofing membranes available, providing the opportunity for customization based on the specific requirements of the museum or art gallery. Some membranes are specially designed to withstand high water pressure, making them suitable for areas prone to heavy rainfall or potential flooding. Ultimately, incorporating a waterproofing membrane in museums or art galleries is an effective measure to safeguard the valuable contents of these establishments, ensuring their preservation for future generations to appreciate.

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Yes, a waterproofing membrane can be used in conjunction with tile or stone installations.

Send your message to us

EPDM Coiled Rubber Waterproof Membrane/waterproofing membrane/lastomeric waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords