EPDM Rubber Coiled Waterproof Membrane for Public

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Coiled Waterproof Membrane for Public

Description Of EPDM Rubber Coiled Waterproof Membrane for Public:

•EPDM waterproof sheet has excellent anti-ozone-aging performance, able to resist ultraviolet light and corrosion of many chemical corrosive materials in the atmosphere

•It has high tensile strength, high ductility and strong retractility, it has excellent crack resistance, able to effect waterproof function even with tiny vibration of buildings.

• Excellent resistance to ozone, oxidation and sunlight.

• Resistance to chemicals; resistant to most inorganic products.

Main Features of EPDM Rubber Coiled Waterproof Membrane for Public:

1>Excellent antiaging performance, service life up to 50 years

2>Working well with in 40C to 100C,it canbe constructed with a single layer in ambient temperature.

3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures.

4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

10>Convenient maitenance, low cost.

Specifications of EPDM Rubber Coiled Waterproof Membrane for Public:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Rubber Coiled Waterproof Membrane for Public:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

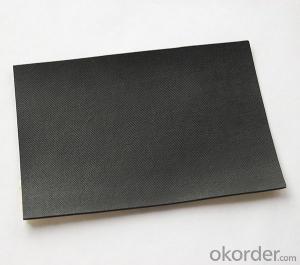

IMages of EPDM Rubber Coiled Waterproof Membrane for Public:

FAQ of EPDM Rubber Coiled Waterproof Membrane for Public:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage. The membrane can be applied to various surfaces, including walls, floors, and roofs, helping to prevent water penetration and moisture-related issues. In theaters or concert halls, where there may be a significant risk of water damage due to heavy rain, leaks, or potential spills, using a waterproofing membrane can provide an extra layer of protection and help preserve the structural integrity of the building.

- Q: Are waterproofing membranes resistant to water vapor transmission?

- Waterproofing membranes possess a resistance to the transmission of water vapor. These membranes function to construct a barrier, effectively hindering water penetration. Typically composed of impermeable materials like rubber, plastic, or bitumen, they effectively obstruct the flow of liquid water, preventing its infiltration into the underlying structure. Nevertheless, it is worth noting that although waterproofing membranes can effectively resist the transmission of water vapor, it may not entirely eradicate it. A certain degree of water vapor may still manage to permeate the membrane, albeit significantly reduced in comparison to materials not specifically intended for waterproofing.

- Q: Can a waterproofing membrane be used on stucco surfaces?

- Yes, a waterproofing membrane can be used on stucco surfaces. Stucco is a porous material that can absorb water, so applying a waterproofing membrane can help prevent water infiltration and damage. The waterproofing membrane acts as a barrier, preventing water from seeping through the stucco and into the underlying structure. It also helps to protect the stucco from moisture-related issues such as cracking, mold, and mildew. It is important to choose a waterproofing membrane that is specifically designed for stucco surfaces and to follow the manufacturer's instructions for proper application. Additionally, regular inspections and maintenance of the waterproofing membrane are recommended to ensure its effectiveness and longevity.

- Q: 1.2 thick synthetic polymer waterproofing membrane two weight how to count

- Waterproof to do in what position, the specific requirements, you can contact me, I have a contact in space, the specific use of what materials, synthetic polymer points several categories, the same material is not the same cost

- Q: Are waterproofing membranes resistant to impact damage?

- Waterproofing membranes are designed to provide protection against water infiltration and are generally resistant to impact damage. However, the level of impact resistance may vary depending on the specific type and quality of the membrane. In general, high-quality waterproofing membranes are engineered to withstand normal impacts and stresses that occur during installation and use. They are typically manufactured using durable materials, such as modified bitumen, rubberized asphalt, or synthetic polymers, which enhance their strength and resilience. While waterproofing membranes can resist minor impact damage, they are not entirely immune to more significant impacts. Heavy impacts, such as dropping heavy objects or sharp objects falling onto the membrane, can potentially cause damage, such as punctures or tears. In such cases, the integrity of the waterproofing system could be compromised, leading to water infiltration and potential structural issues. To enhance impact resistance, additional protective measures can be taken, such as installing a protective layer or using reinforced membranes. These additional layers or reinforcements can provide an extra barrier against impact damage, ensuring the long-term performance and durability of the waterproofing system. Overall, while waterproofing membranes are generally resistant to impact damage, it is important to handle them with care during installation and avoid any unnecessary impacts that could potentially compromise their integrity.

- Q: How does a waterproofing membrane handle movement in structural elements?

- A waterproofing membrane is designed to handle movement in structural elements by being flexible and accommodating any shifts or expansions that may occur. It can stretch and contract with the movement of the building, ensuring that it remains intact and continues to provide a watertight barrier.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage. The membrane can be applied to various surfaces, including walls, floors, and roofs, helping to prevent water penetration and moisture-related issues. In theaters or concert halls, where there may be a significant risk of water damage due to heavy rain, leaks, or potential spills, using a waterproofing membrane can provide an extra layer of protection and help preserve the structural integrity of the building.

- Q: Can a waterproofing membrane be used for a stadium roof?

- Indeed, a waterproofing membrane proves to be a valuable asset when it comes to shielding a stadium roof. It is a widely adopted solution in the realm of construction, particularly for rooftops, as it effectively wards off water infiltration and safeguards the underlying structure against potential water-related harm. This membrane serves as a protective barrier against moisture and is specifically engineered to endure harsh external elements such as rain, snow, and UV radiation. By employing a waterproofing membrane on a stadium roof, it significantly bolsters its resistance to water, thereby averting leaks. This aspect is of utmost importance as it ensures the stadium's integrity remains intact, while also safeguarding spectators, equipment, and facilities within. Moreover, the versatility of waterproofing membranes is noteworthy, as they are available in various types and materials, allowing for customization to meet the specific requirements and design of the stadium roof.

- Q: Can a waterproofing membrane be used for shipping containers or cargo holds?

- Indeed, shipping containers or cargo holds can benefit from the utilization of waterproofing membranes. These membranes are specifically engineered to act as a shield against moisture, effectively thwarting any potential water seepage. When applied to the internal or external surfaces of shipping containers or cargo holds, these waterproofing membranes prove instrumental in safeguarding the contents from any water-related harm during transportation. This becomes particularly crucial when dealing with valuable or delicate goods that are susceptible to moisture-induced deterioration. Moreover, the application of waterproofing membranes aids in preventing the formation of rust and corrosion on the metal surfaces of containers, thereby ensuring their endurance and longevity in the long run.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. Laundry rooms are areas where water and moisture are commonly present due to washing machines, sinks, and other water-related activities. Installing a waterproofing membrane in the laundry room can help prevent water damage to the walls, floors, and other structural components. It acts as a barrier against water penetration, ensuring that any water or moisture that accumulates in the room does not seep into the underlying surfaces. This can be particularly beneficial in laundry rooms located on upper floors or in areas prone to high humidity or flooding. By using a waterproofing membrane, homeowners can protect their laundry rooms from potential water-related issues, such as mold growth, rotting, or structural damage.

Send your message to us

EPDM Rubber Coiled Waterproof Membrane for Public

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords