EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness

Description Of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

Main Features of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

A.Polyester based SBS Modified Bitumen Waterproofing Membrane

a. Strong impermeability

b. High tensile strength, elongation, ability to adapt the grassroots shrinkage deformation and cracking

c. Puncture-resistant, broken resistant, tear-resistant

d. The corrosion resistance, resistance to mildew, weathering good

e. Construction convenient, hot-melt can be operated Four Seasons Construction, reliable joints

B. Fiberglass based SBS Modified Bitumen Waterproofing Membrane

a. High tensile strength, stability of a good size

b. High Temperature good performance

c. Damage resistance, corrosion resistance, resistance to mildew, weathering good performance

d. Good construction performance, reliable joints.

Specifications of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geo-synthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation

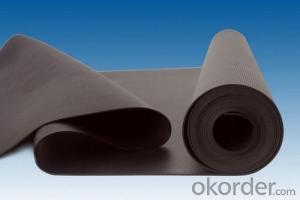

IMages of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

FAQ of EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, a waterproofing membrane can be used in bridge decks or roadways to enhance durability, prevent water damage, and extend the lifespan of the structure.

- Q: Can a waterproofing membrane be painted over?

- Yes, a waterproofing membrane can be painted over. However, it is important to ensure that the membrane is properly prepared and any necessary primers or sealers are applied before painting. It is also recommended to use a paint specifically designed for application on waterproofing membranes to ensure durability and long-lasting results.

- Q: Can a waterproofing membrane be used on precast galvanized surfaces?

- Precast galvanized surfaces can benefit from the use of a waterproofing membrane. This membrane serves as a safeguard against water infiltration and can be applied to various surfaces, including precast galvanized ones. By preventing water from seeping into the surface, the membrane safeguards the underlying structure from moisture damage. However, it is crucial to prepare the precast galvanized surface adequately before applying the membrane. This involves removing any loose or flaking galvanized coating to ensure proper adhesion of the membrane. Furthermore, it is recommended to consult the manufacturer or supplier of the waterproofing membrane to guarantee compatibility with galvanized surfaces and to follow their recommended application guidelines for optimal outcomes.

- Q: Can a waterproofing membrane be used on fiberglass surfaces?

- Yes, a waterproofing membrane can be used on fiberglass surfaces. Fiberglass is a non-porous material, which means it does not absorb or retain water. However, it is still susceptible to water damage if not properly protected. Applying a waterproofing membrane on fiberglass surfaces creates an additional barrier that prevents water from seeping into the material and causing damage. This can be particularly important in areas such as bathrooms, showers, or swimming pools, where fiberglass is commonly used. The waterproofing membrane acts as a protective layer, ensuring that the fiberglass remains dry and preventing any potential water-related issues such as leaks, mold, or deterioration.

- Q: What is the preferred level of waterproofing?

- 3, roof 3 waterproof: Application: general building; Waterproof layer of reasonable use of life: 10 years; Waterproof layer selection of materials: should choose three asphalt four oil asphalt waterproofing membrane, polymer modified asphalt waterproofing membrane, synthetic polymer waterproofing membrane, metal sheet, polymer modified asphalt waterproof coating, synthetic polymer waterproof coating , Fine stone concrete, flat tile, felt tile and other materials;

- Q: How does a waterproofing membrane handle exposure to UV radiation?

- Waterproofing membranes are specifically designed to withstand exposure to UV radiation, which is a common environmental factor that can cause deterioration and degradation of materials over time. In order to counteract the damaging effects of UV radiation, manufacturers typically incorporate UV stabilizers and additives into the production of waterproofing membranes. These substances serve as a barrier, either absorbing or reflecting the UV rays and preventing them from penetrating the membrane. Additionally, certain waterproofing membranes may include extra protective layers or coatings that further enhance their resistance to UV radiation. Ultimately, the inclusion of UV stabilizers and protective layers in waterproofing membranes guarantees their ability to endure prolonged exposure to UV radiation without compromising their performance or integrity.

- Q: Can a waterproofing membrane be used for basements?

- Yes, a waterproofing membrane can be used for basements. In fact, it is one of the most effective solutions for preventing water infiltration and moisture damage in basements. A waterproofing membrane is a thin layer of material that is applied to the exterior walls and/or floors of a basement to create a barrier against water. It is designed to withstand hydrostatic pressure, which is the force exerted by water against the walls and floors. By installing a waterproofing membrane, you can significantly reduce the risk of water damage, mold growth, and structural problems in your basement. It is important to note that proper installation and maintenance of the membrane are crucial for its effectiveness, so it is recommended to consult with a professional waterproofing contractor for the best results.

- Q: What is the cost of a waterproofing membrane?

- The cost of a waterproofing membrane can vary depending on factors such as the type and quality of the membrane, the size of the area to be covered, and the complexity of the installation. It is best to consult with manufacturers or contractors to get accurate cost estimates for specific projects.

- Q: Can a waterproofing membrane be used on swimming pool decks?

- Indeed, swimming pool decks can benefit from the use of a waterproofing membrane. The purpose of these membranes is to effectively block water infiltration, which makes them particularly suitable for safeguarding areas that are constantly exposed to moisture, like swimming pool decks. Typically, these membranes are applied directly onto the deck's surface, creating an impermeable and long-lasting layer. This ensures that water does not permeate the deck, thus averting potential harm caused by dampness, such as cracks, the growth of mold, or structural decline. Furthermore, waterproofing membranes offer additional advantages, including prolonging the lifespan of the deck and enhancing its overall aesthetic appeal.

- Q: Can a waterproofing membrane be used on foam block surfaces?

- Foam block surfaces can benefit from the use of a waterproofing membrane. Foam blocks, like expanded polystyrene (EPS) or extruded polystyrene (XPS), are commonly utilized for insulation in buildings. However, they are not naturally waterproof and can absorb moisture if exposed. To safeguard against water infiltration and potential harm, the application of a waterproofing membrane is recommended. This membrane acts as a protective barrier, preventing water from penetrating the foam and safeguarding it against issues caused by moisture, such as mold, mildew, or degradation. Selecting a waterproofing membrane that is compatible with foam block surfaces is crucial, and it is essential to adhere to the manufacturer's instructions for proper application. It is also advisable to seek guidance from a professional or building engineer to ensure the correct waterproofing solution is chosen for the specific foam block application.

Send your message to us

EPDM Coiled Rubber Waterproof Membrane with 0.8mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords