30 X 37 Aluminum Sheets for Sale - EN AW-3105 Aluminium Treadplate for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 3105 Aluminium Treadplate for Building Description

EN AW - 3105 Aluminium Treadplate for Building is one semi-finished aluminium material. The alloy AA3105 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 3105 Aluminium Treadplate for Building

EN AW - 3105 Aluminium Treadplate for Building | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 3105 Aluminium Treadplate for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 3105 Aluminium Treadplate for Building

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 3105 Aluminium Treadplate for Building

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

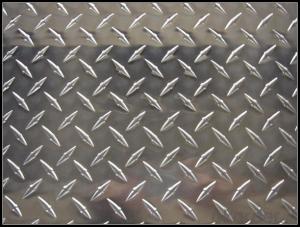

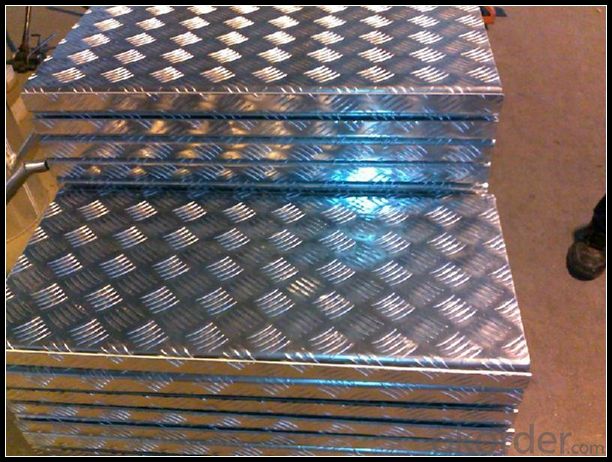

6. Image of EN AW - 3105 Aluminium Treadplate for Building

7. Package and shipping of EN AW - 3003 Aluminium Sheet for Circle

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- The aluminum will hurt more with the reverberation that travels through the bat. Hence you see the rubber padding on the bat, along with wearing batting gloves. Would also sends some strong vibrations through the hands when the ball is struck in certain positions, however, catch a tough pitch with that aluminum without a batting glove and your hands will be stinging.

- Q: Are aluminum sheets suitable for food processing equipment?

- Yes, aluminum sheets are suitable for food processing equipment. Aluminum is a widely used material in the food processing industry due to its excellent properties. It is corrosion-resistant, lightweight, and has good thermal conductivity, making it ideal for applications where hygiene and efficient heat transfer are crucial. Additionally, aluminum is non-toxic and does not react with food, ensuring that it does not affect the taste or quality of the processed products. Overall, aluminum sheets are a popular choice for food processing equipment as they meet the necessary safety and performance requirements.

- Q: Are aluminum sheets suitable for food packaging?

- Aluminum sheets prove to be a suitable option for food packaging. The food industry widely embraces aluminum due to its unique attributes. Its lightweight nature, flexibility, and exceptional barrier properties shield the contents from external factors like moisture, light, and oxygen. Consequently, these properties help maintain the freshness and quality of the food products. In addition, aluminum resists corrosion and does not interact with acidic or alkaline substances, guaranteeing the preservation of taste and quality. Moreover, aluminum sheets can be effortlessly molded into diverse shapes, making them perfect for various forms of food packaging such as trays, containers, and foil wraps. All in all, aluminum sheets offer a safe and efficient choice for food packaging, ensuring durability, protection, and convenience.

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Figure out the Eknots using a chart. Cu -- Cu2+ = Enot of ? Al3+ --- Al = Enot of ? It needs to be positive to spontaneously react. I believe from memory that Al -- Al3+ is 1.3volts, so the reverse is negative. Meanwhile Cu is something under .5 volts, so it won't be enough to make the reaction work. This is further understood because aluminum requires a lot of energy to smelt from the oxide (which is the reverse reaction of Al3+ -- Al that you're talking about here) Secondly, do your homework man, it's REALLY obnoxious to add the why or why not and phrase everything exactly as your homework asks. Try to ask a question about the topic so you actually learn. For example, what are reduction potentials in terms of, for example, Cu --- Cu2+

- Q: Also what are some intersting facts about Aluminum? (the element) thanks 2 any 1 who answers =)

- Aluminum is a versatile material with vast applications in engineering, aerospace and automotive industries. Some of its desirable properties include lightweight (relative to steel) and high strength. The metal is however rarely used in its pure form, it is often alloyed with other elements such as Mg, Manganese, chromium, Titanium to fine tune its mechanical, chemical and or physical properties and tailor it to specific applications. However, in some applications other materials are preferred, for example, Magnesium, due to its higher strength to weight ratio is increasingly replacing Al in transmission casing of automobiles. Also, Compacted Graphite cast Iron is preferred in engine blocks because of its superior strength at high tempreatures, dimensional stability and wear resistance. Auto engines work at very tempreatures and alloys that are capable of withstanding high pressures while maintaining stability are critical. CGCI performs better than Al in this situation. Al alloys remains an important engineering materials though.

- Q: Is aluminum sheet corrosion-resistant?

- Yes, aluminum sheet is corrosion-resistant. Aluminum forms a protective oxide layer on its surface when exposed to oxygen in the air, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from moisture, chemicals, and other corrosive elements. Additionally, aluminum has a high resistance to corrosion caused by saltwater, making it a popular choice for marine applications. However, it is important to note that certain conditions, such as exposure to acidic or alkaline environments, can still cause corrosion on aluminum surfaces if not properly maintained or protected.

- Q: This question asks for a list of the various types of profiles that can be made from aluminum sheets.

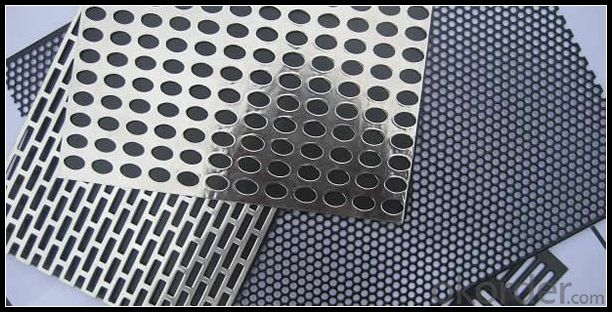

- <p>Aluminum sheet profiles come in a variety of types, suitable for different applications. Some common types include: 1. Flat Sheets: These are simple, flat aluminum sheets with no bends or curves. 2. Corrugated Sheets: These have a wavy or ridged pattern, providing strength while allowing flexibility. 3. Perforated Sheets: These have holes punched in a regular pattern, useful for ventilation or decorative purposes. 4. Embossed Sheets: These have a raised pattern on the surface, often used for aesthetic or functional reasons. 5. Extruded Profiles: These are complex shapes created by pushing aluminum through a die, suitable for structural applications. 6. Expanded Metal Sheets: These have a diamond-shaped pattern, providing strength and rigidity. 7. Checkered Plates: These have a raised, non-slip pattern, often used for flooring. Each type has its own specific uses and properties, and the choice depends on the requirements of the project.</p>

- Q: Could ring-pull can be transformed as aluminum sheet?

- Yes, but the ring-pull cans contains fewer aluminum.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

Send your message to us

30 X 37 Aluminum Sheets for Sale - EN AW-3105 Aluminium Treadplate for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords