3000 Diamond Aluminum Tread Plate for Boats - Aluminum Sheets for Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of 3000 Diamond Aluminum Tread Plate for Transportation

Thickness: 0.8-6.35mm

Width: 800-1600mm

Length: 800-8000mm

Material (alloy): 3003, 3003

Temper: H22 H24 H26

Surface Treatment: Embossed

Pattern: Diamond pattern,5bars patern,3bars pattern,bean pattern,indicator pattern

2. Feature of 3000 Diamond Aluminum Tread Plate for Transportation

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

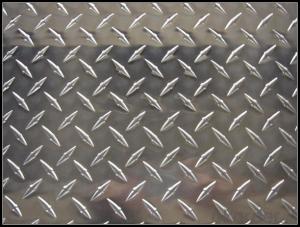

4. Image of 3000 Diamond Aluminum Tread Plate for Transportation

5. Package and shipping of Aluminium Coils for Industrial Applications

eye to sky

eye to wall

with wooden pallet (wooden case also available)

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Yes, aluminum sheets are suitable for manufacturing architectural roof systems. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. These qualities make it ideal for withstanding various weather conditions, including high winds, rain, and snow. Additionally, aluminum can be easily fabricated and shaped into different forms, allowing for flexibility in design and installation. It is also a sustainable and environmentally friendly option as it can be recycled. Overall, the use of aluminum sheets in manufacturing architectural roof systems offers numerous benefits and is a suitable choice for this application.

- Q: Can aluminum sheets be used for food processing conveyors?

- Yes, aluminum sheets can be used for food processing conveyors. Aluminum is a popular choice for food processing equipment due to its many desirable properties. It is lightweight, corrosion-resistant, and has excellent thermal conductivity. These features make aluminum sheets ideal for use in food processing conveyors, as they can withstand the demanding environment of food production while ensuring efficient and safe transportation of food products. Additionally, aluminum is easy to clean and maintain, making it a hygienic choice for food processing applications.

- Q: What are the different methods of finishing aluminum sheet edges?

- There are several methods that can be used to finish aluminum sheet edges, depending on the desired outcome and application. One common method is deburring, which involves removing any sharp or rough edges from the aluminum sheet. This can be done using various tools such as files, sandpaper, or specialized deburring machines. Deburring not only improves the appearance of the edges but also helps to prevent any potential injuries or accidents caused by sharp edges. Another method is chamfering, which involves creating a beveled edge on the aluminum sheet. This can be achieved using chamfering tools or by carefully filing or sanding the edges at a specific angle. Chamfering is often done to enhance the aesthetics of the aluminum sheet and to make it easier to handle and assemble. Additionally, edge rounding is a technique that involves smoothing the edges of the aluminum sheet to create a rounded or curved profile. This can be done using tools such as sanders, grinders, or specialized edge rounding machines. Edge rounding not only improves the visual appeal of the aluminum sheet but also helps to reduce the risk of injury from sharp edges. Furthermore, anodizing is a popular finishing method for aluminum sheet edges. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This not only enhances the corrosion resistance of the aluminum but also provides a range of color options for the edges, allowing for customization and improved aesthetics. Lastly, powder coating is another method that can be used to finish aluminum sheet edges. Powder coating involves applying a dry powder onto the surface of the aluminum and then heating it to create a durable and decorative finish. This method offers a wide variety of colors, textures, and finishes, allowing for customization and enhanced visual appeal. Overall, the choice of finishing method for aluminum sheet edges will depend on factors such as the desired appearance, functionality, and application requirements. It is important to consider these factors and consult with experts to determine the most suitable method for a specific project.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Thanks, have all of the above that you mentioned...just that a few are favorites as I can pick them up easily - bad shoulders and elbows have weight bearing issues....I don't even cook all that much, but seem to burn a lot - even when boiling eggs....it is a miserable commentary on a day in the life of Aunt Susie....

- Q: What is the typical sheet size tolerance for aluminum sheets?

- The typical sheet size tolerance for aluminum sheets can vary depending on the specific application and industry standards. However, in general, the industry standard for aluminum sheet size tolerance is typically around +/- 0.005 inches. This means that the actual size of the aluminum sheet can deviate up to 0.005 inches from the specified or desired size. It is important to note that this tolerance can be further reduced or increased based on the specific requirements of the project or customer preferences. Additionally, it is advisable to consult the manufacturer or supplier of the aluminum sheets to get the most accurate and up-to-date information on sheet size tolerances, as they may have specific guidelines or capabilities that differ from the industry standard.

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: Can the aluminum sheets be painted or coated with a different color?

- Yes, aluminum sheets can be painted or coated with a different color. Aluminum is a versatile material that can be easily painted or coated to achieve a desired color or finish. This can be done through various methods such as powder coating, anodizing, or using liquid paint. These processes provide a protective layer on the surface of the aluminum sheet while giving it a different color or appearance. The choice of paint or coating will depend on the specific requirements and desired outcome. Overall, painting or coating aluminum sheets is a common practice and allows for customization and aesthetic enhancement.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is known for its excellent resistance to corrosion, which makes it an ideal choice for outdoor use. It does not rust or deteriorate when exposed to moisture or extreme weather conditions. Additionally, aluminum sheets are lightweight, yet strong and durable, making them suitable for various outdoor applications such as roofing, siding, gutters, and outdoor signage. They are also easy to maintain and can be painted or coated to enhance their appearance and further protect against the elements. Overall, aluminum sheets are a reliable and versatile option for outdoor applications.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

Send your message to us

3000 Diamond Aluminum Tread Plate for Boats - Aluminum Sheets for Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords