Forming Aluminum Sheets - Embossed Sheet Anti-Slip Step for Sale China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

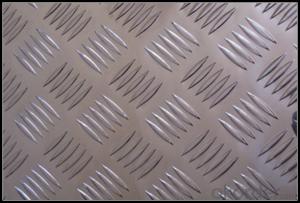

1.Structure of Embossed Sheet Anti-slip Step for Sale China Supplier

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Embossed Sheet Anti-slip Step for Sale China Supplier

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Embossed Sheet Anti-slip Step for Sale China Supplier Images

4.Specification of Embossed Sheet Anti-slip Step for Sale China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: What are the specific rules or codes that govern the use of aluminum sheets in residential construction?

- <p>Yes, there are special regulations related to using aluminum sheets in residential buildings. These regulations can vary by country, state, or municipality, but generally, they cover aspects such as material standards, fire resistance, structural integrity, and energy efficiency. For example, aluminum sheets must meet specific thickness and strength requirements to ensure structural safety. They must also comply with fire codes, which may require certain fire-resistant coatings or treatments. Additionally, energy codes may dictate the insulation value of aluminum sheets used in walls or roofs to improve thermal performance. It's crucial to consult local building codes and regulations to ensure compliance when using aluminum sheets in residential construction.</p>

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage due to its durability, lightweight nature, and resistance to corrosion, making it a popular choice for a wide range of indoor and outdoor signage applications.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Aluminum extruded radiator:It is widely used in modern material with good heat dissipation cooling industry, most of them use 6063 T5 high quality aluminum, its purity can reach above 98%, the heat conduction ability, low density, low price so get the favor of the major manufacturers.

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Indeed, 101 aluminum sheets possess the potential to serve as a valuable resource in the creation of sporting goods. The versatility of aluminum as a material grants numerous advantages to sporting equipment. Notably, its lightweight nature becomes paramount when it comes to various sports gear such as bicycles, tennis rackets, and baseball bats. This attribute facilitates effortless handling and enhances maneuverability. Furthermore, aluminum boasts corrosion resistance, ensuring the durability of sporting goods even when exposed to diverse weather conditions. Moreover, its exceptional strength-to-weight ratio renders it suitable for high-performance equipment, enabling durability without unnecessary bulk. Consequently, the utilization of 101 aluminum sheets emerges as a viable option for manufacturing a wide range of sporting goods, effectively delivering the desired properties essential for optimum performance, longevity, and user satisfaction.

- Q: Can aluminum sheets be used for water tanks?

- Water tanks can indeed utilize aluminum sheets. Thanks to its lightweight nature and resistance to corrosion, aluminum is an ideal material for water storage. Its durability and ability to fend off rust and corrosion have made it a popular choice in industries like aerospace and marine. Furthermore, aluminum tanks are simpler to transport and install in comparison to alternative materials, and they can endure high pressure and extreme temperatures. Nonetheless, it is crucial to guarantee that the aluminum sheets employed for water tanks are of exceptional quality and adhere to the required standards to uphold the tank's safety and longevity.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

Send your message to us

Forming Aluminum Sheets - Embossed Sheet Anti-Slip Step for Sale China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords