American Made Aluminum Sheets - Aluminum Alloy Sheets for Sale China Manufacturer Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

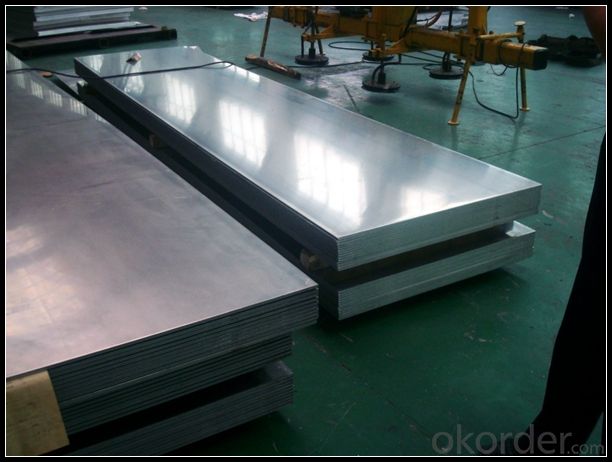

1. Specification of Aluminum Alloy Sheetss for Sale China Manufacturer Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Aluminum Alloy Sheetss for Sale China Manufacturer Supplier

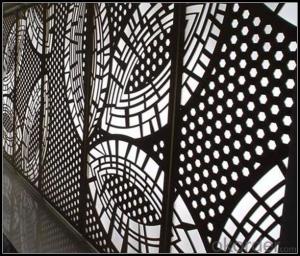

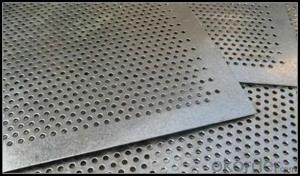

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Alloy Sheetss for Sale China Manufacturer Supplier

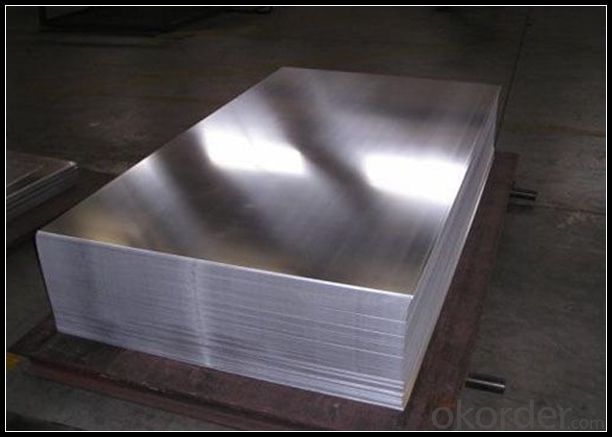

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

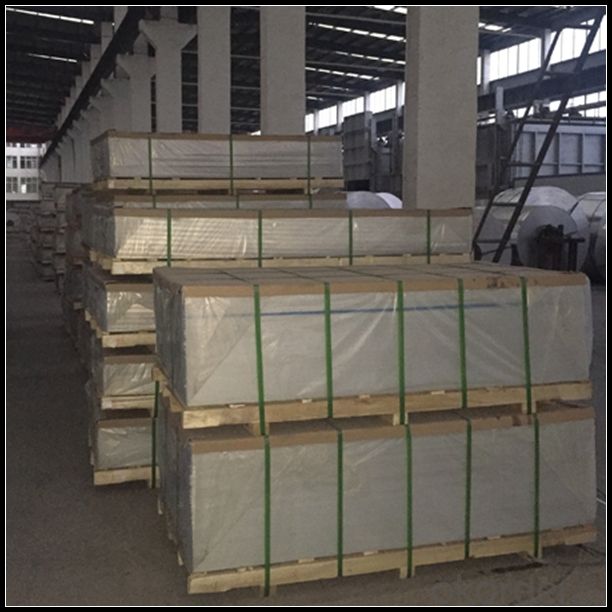

5. Image of Aluminum Alloy Sheetss for Sale China Manufacturer Supplier

6. Package and shipping of Aluminum Alloy Sheetss for Sale China Manufacturer Supplier

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: What is the thickness of an aluminum sheet?

- The specific application and requirements determine the variability in the thickness of an aluminum sheet. A wide variety of thicknesses, usually ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even more, can be found in aluminum sheets. Gauge is the usual unit of measurement for thickness, where higher gauge numbers indicate thinner sheets. To choose the right thickness for an aluminum sheet, one must consider the intended use and desired properties like strength, flexibility, or weight.

- Q: Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets can be suitable for chemical reactors depending on the specific application and conditions. Aluminum is known for its excellent corrosion resistance, especially when exposed to air or water, due to the formation of a protective oxide layer. This makes it suitable for many chemical reactions that involve non-aggressive substances. However, it is important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions, as these can corrode the oxide layer and lead to degradation of the metal. Additionally, aluminum may react with certain chemicals, such as strong oxidizers, halogens, or strong bases, which could compromise the integrity of the reactor. In cases where aluminum is used in chemical reactors, it is common to employ protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings can provide an additional barrier between the aluminum and the reactants, ensuring a safe and effective operation. Ultimately, the suitability of aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the necessary level of corrosion resistance. It is always advisable to consult with experts and consider the compatibility of materials before selecting aluminum for such applications.

- Q: A sample of aluminum and a sample of steel have superficially identical microstructures. Which would you expect to be stronger, and why?

- as far as i know we have an alloy named dur alumin cosists of Al, alloying element especially Mg it is as strong as steel .

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets varies depending on the supplier and the specific requirements. However, standard widths for aluminum sheets typically range from 36 inches to 72 inches.

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: Can aluminum sheets be used for storage tanks?

- Yes, aluminum sheets can be used for storage tanks. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for storing various substances such as water, chemicals, and fuel. It offers excellent durability and can withstand harsh environmental conditions. Additionally, aluminum tanks are relatively easy to construct and maintain. However, it is important to consider the specific requirements of the substance being stored and consult with experts or engineers to ensure that aluminum sheets are the appropriate choice for the storage tank in question.

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

Send your message to us

American Made Aluminum Sheets - Aluminum Alloy Sheets for Sale China Manufacturer Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords