Aluminum Perforated Sheets - Embossed Aluminum Sheet 5052 for Anti-Slipped Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Embossed Aluminum Sheet 5052 for Anti-slipped Step

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Embossed Aluminum Sheet 5052 for Anti-slipped Step

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

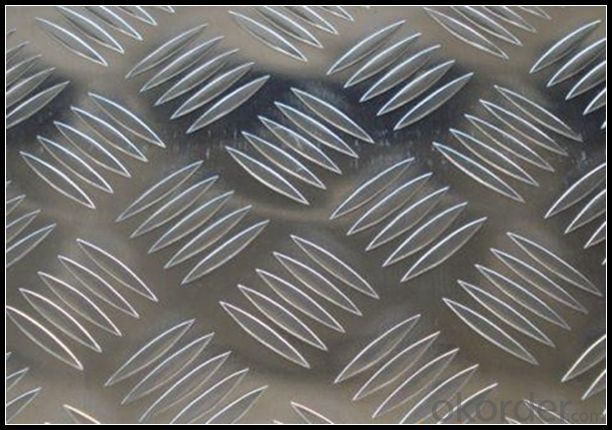

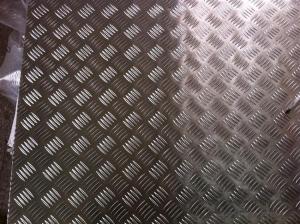

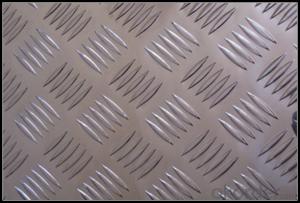

3. Embossed Aluminum Sheet 5052 for Anti-slipped Step Images

4.Specification of Aluminum Sheet 6061 for Window And Door System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminum would only make sense in low current applications where cost and weight are important.

- Q: Is it possible to utilize aluminum sheets as a material for constructing roofs?

- <p>Yes, aluminum sheets can be used for roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also energy-efficient, reflecting heat and reducing cooling costs. It's recyclable and has a long lifespan, making it an environmentally friendly choice. However, it may not be as impact-resistant as some other materials and can be more expensive upfront.</p>

- Q: 3mm heavy aluminum plate, multiple cubic meters per cubic meter?

- Long by wide by high density is multiplied by the weight. The density of aluminum is different according to the different metal content, one to eight series aluminum density is between 2.71-2.75.

- Q: How are aluminum sheets different from aluminum plate?

- Aluminum sheets and aluminum plates are two forms of aluminum metal that differ primarily in terms of thickness. Aluminum sheets are typically thin, flat pieces of aluminum that are less than 6mm thick. They are commonly used in applications where lightweight and flexibility are important, such as in the construction of aircrafts, automobiles, and electronic devices. On the other hand, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are often used in applications that require strength and durability, such as in the construction of heavy machinery, structural supports, and marine equipment. While both sheets and plates are made from aluminum, their distinct thicknesses make them suitable for different purposes.

- Q: How do you prevent warping of aluminum sheets during machining?

- There are several measures that can be taken to prevent warping of aluminum sheets during machining: 1. Proper material selection is crucial in minimizing warping. Opt for aluminum alloys with lower levels of thermal expansion, like 6061 or 7075, as they are less prone to warping. 2. It is recommended to stabilize the material before machining by annealing or stress-relieving the aluminum sheets. This process reduces internal stresses and decreases the likelihood of warping. 3. Ensure the use of appropriate cutting tools. Opt for tools with sharp edges and proper geometry to minimize heat generation and facilitate efficient chip removal. Carbide or diamond-coated tools are often preferred for their high heat resistance when machining aluminum. 4. Minimize heat generation during machining, as excessive heat can cause warping. Implement the use of coolant or lubricants to reduce friction and dissipate heat. Continuous cooling helps maintain a stable temperature and prevents warping. 5. Properly control cutting parameters such as cutting speed, feed rate, and depth of cut to prevent warping. High cutting speeds or excessive material removal rates generate excessive heat, which leads to warping. Experimentation and experience should determine the optimal parameters. 6. Use appropriate fixturing during machining to minimize the chances of warping. Securely clamp the aluminum sheets using suitable fixtures or jigs to maintain stability and prevent movement. 7. Consider employing machining techniques like climb milling or ramping, which reduce vibrations and ensure a smoother cutting process, thereby reducing the risk of warping. 8. After machining, it is advisable to stress-relieve the aluminum sheets again. This step further reduces any residual stress that may have developed during the machining process. By adhering to these steps, the chances of warping during the machining of aluminum sheets can be significantly reduced, resulting in high-quality finished products.

- Q: What are the different types of alloys used for aluminum sheets?

- Aluminum sheets can be made from different types of alloys, each with its own unique properties and uses. Here are some of the most commonly used ones: - The 1100 alloy is pure aluminum and has excellent resistance to corrosion and good formability. It is often utilized for general sheet metal work like roofing and siding. - The 3003 alloy is similar to 1100 but contains added manganese, which makes it slightly stronger. It is commonly employed for applications that require moderate strength and good resistance to corrosion, such as packaging and automotive parts. - The 5052 alloy is renowned for its exceptional corrosion resistance, particularly in marine environments. It is also highly formable and weldable, making it suitable for various applications like fuel tanks, marine components, and architectural panels. - The 6061 alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and resistance to corrosion. It is commonly found in structural applications like aircraft parts, bicycle frames, and automotive components. - The 7075 alloy is a high-strength alloy frequently utilized in aerospace and military applications. It exhibits excellent resistance to fatigue and is easily machinable. It is typically employed for aircraft structures, missile parts, and high-stress components. These examples illustrate the variety of aluminum alloys available for sheet production. The choice of a specific alloy depends on desired properties, such as strength, resistance to corrosion, formability, and cost, as well as the intended application.

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can be used for packaging applications. It is a widely used material in the packaging industry due to its excellent properties such as lightweight, durability, and resistance to corrosion. Aluminum sheets are commonly used for packaging food, beverages, pharmaceuticals, and various consumer products.

- Q: Can aluminum sheets be used in automotive applications?

- Aluminum sheets find their utility in automotive applications. This lightweight and sturdy material brings a multitude of advantages to the manufacturing of automobiles. It is widely employed in the creation of car bodies, hoods, doors, roofs, and various other components. By incorporating aluminum sheets into automotive applications, the overall weight of the vehicle can be reduced, thereby enhancing both fuel efficiency and performance. Moreover, aluminum boasts exceptional resistance to corrosion, making it well-suited for enduring harsh weather conditions and exposure to road salt. Additionally, aluminum can be easily molded and shaped, facilitating intricate designs and detailing on automotive parts. In summary, the utilization of aluminum sheets in automotive applications contributes to the creation of vehicles that are lighter, more fuel-efficient, and visually appealing.

- Q: What is the thickness range available for 101 aluminum sheets?

- The thickness range available for 101 aluminum sheets typically varies from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm).

- Q: What are the different types of finishes available for painted aluminum sheets?

- Painted aluminum sheets come in various finishes, each with its own distinct features and advantages. 1. For a non-reflective and dull appearance, the matte finish is ideal. This option is commonly utilized in architectural elements and interior design for a low-gloss look. 2. If you prefer a shiny and reflective surface, the gloss finish is the way to go. This finish is often chosen for automotive parts and decorative panels, giving them a sleek and polished appearance. 3. To add texture and patterns to the painted aluminum sheet, opt for a textured finish. This type of finish is commonly used for decorative purposes, enhancing visual appeal and providing a unique tactile experience. 4. Achieve a metallic appearance resembling stainless steel or bronze with a metallic finish. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder coating is a popular finishing method where a dry powder is applied to the painted aluminum sheet and cured under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Protect and enhance the durability of a painted aluminum sheet with a clear coat finish. This transparent finish provides an extra layer of protection against UV rays, moisture, and other environmental factors. Consider the intended use and desired aesthetic when selecting a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

Send your message to us

Aluminum Perforated Sheets - Embossed Aluminum Sheet 5052 for Anti-Slipped Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords