Textured Aluminum Sheets - Rolls of Aluminum for Sale Made in China Markets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

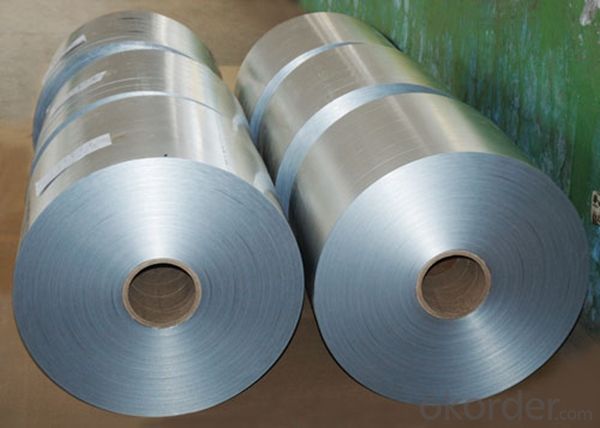

1.Structure of Rolls Of Aluminum for Sale Made in China Markets

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Rolls Of Aluminum for Sale Made in China Markets

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Rolls Of Aluminum for Sale Made in China Markets Images

4.Specification of Rolls Of Aluminum for Sale Made in China Markets

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- Get ahold of a polishing companys cataloge. The have all kinds of felt polishing wheels in all shaps and sizes.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: How do you cut aluminum sheets?

- To cut aluminum sheets, you can use various methods depending on the thickness and size of the sheet. Here are a few common methods: 1. Hand shears: For thin aluminum sheets, hand shears can be effective. These are handheld tools with sharp blades that can cut through the sheet by applying manual force. 2. Power shears: For thicker aluminum sheets, power shears are a better option. These electric or pneumatic tools have powerful blades that can cut through the material with ease. They are especially useful for straight cuts. 3. Jigsaw: A jigsaw with a metal-cutting blade can be used to cut aluminum sheets, especially when you need to make curved or irregular cuts. Make sure to use a blade specifically designed for cutting metal. 4. Circular saw: A circular saw with a carbide-tipped blade can also be used to cut aluminum sheets. This method is suitable for straight cuts and requires the sheet to be clamped securely to avoid vibrations during cutting. 5. CNC cutting: Computer Numerical Control (CNC) machines can be used to accurately cut aluminum sheets into precise shapes and sizes. These machines use computer programs to control the cutting process, making them ideal for complex or repetitive cuts. Before cutting aluminum sheets, ensure you wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from any sharp edges or metal shavings. It is also advisable to secure the sheet firmly in place using clamps or a vise to prevent movement during cutting.

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- I helped a friend restore an old Honda 160. We did a combination of the things mentioned. We painted the engine cases with a high temp aluminum paint. We did the side covers by wet sanding with 400-800-1000 and then finishing with Semichrome. Other misc bits we went with flat black (makes the polished aluminum pop). It wasn't exactly stock, but it looked great. It would take an expert to know the difference.

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating.

- Q: What are the different grades of aluminum sheet?

- The market offers a variety of aluminum sheet grades, each possessing unique properties and applications. Some notable grades are as follows: 1. Grade 1100: Renowned for its exceptional resistance to corrosion and high thermal conductivity. It finds common usage in chemical equipment, reflectors, heat exchangers, and electrical conductors. 2. Grade 3003: This grade contains manganese, rendering it highly resistant to corrosion. It is frequently employed in cooking utensils, storage tanks, and architectural trim. 3. Grade 5052: Exhibits good formability and high fatigue strength. It is frequently utilized in marine applications such as boat hulls and components, as well as in aircraft fuel tanks and structural parts. 4. Grade 6061: Distinguished by its excellent strength-to-weight ratio and favorable machinability. It is commonly employed in automotive parts, bicycle frames, and structural components. 5. Grade 7075: Possesses exceptional strength and toughness, making it suitable for aerospace applications, including aircraft wings and fuselage structures. Every aluminum sheet grade possesses unique characteristics and is selected based on specific application requirements. Factors such as corrosion resistance, strength, formability, and machinability should be carefully considered when determining the appropriate grade.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Textured Aluminum Sheets - Rolls of Aluminum for Sale Made in China Markets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords