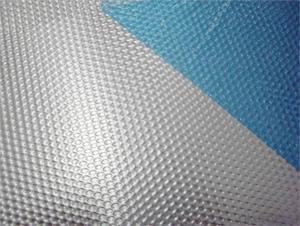

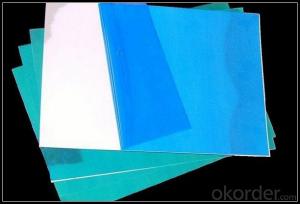

Light Gauge Embossed Aluminum Sheet and Coil Series 1/3/5/8 - Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We are specializes in manufacturing Aluminium sheets,aluminum coils,Aluminum Foils and Aluminum Strips,PE plate substrate.

And we also can customize for different clients. If you are interested in, please don't hesitate to contatc me!

Aluminum sheets | ||||||

Alloy | 1050,1060,1070,1100,1145,1235 | O,H12,H22,H14,H24,H16,H26,H18 | ||||

3003,3004,3014,3105,3102 | O,H12,H22,H14,H24,H16,H26,H18 | |||||

5052,5754,5005,5083 | O,H12,H22,H14,H24,H16,H26,H18 | |||||

8011 | O,H12,H22,H14,H24,H16,H26,H18 | |||||

Specification |

Kindly Notice:dimensions also can be produced as your party request | |||||

Packing: | standard export packing,wooden pallet

| |||||

Delivery Time | 20 days after receiving your depoist or original L/C | |||||

Minimum Order | 5 tons | |||||

The term of Payment | T/T, Irrevocable L/C at sight. | |||||

Application | Mainly used in Construction , decoration,packaging, printing, cover material,piping, electronic elements, referigeration, air conditioner, automobile, and so on

| |||||

Surface | Mill Finish or customizing for different clients | |||||

Aluminum coils | | |||||

Alloy | 1050,1060,1070,1100,1145,1235 | O,H12,H22,H14,H24,H16,H26,H18 | ||||

3003,3004,3014,3105,3102 | O,H12,H22,H14,H24,H16,H26,H18,H28 | |||||

5052,5754,5005,5083 | ||||||

8011 | O,H12,H22,H14,H24,H16,H26,H18 | |||||

Specification |

Kindly Notice:dimensions also can be produced as your party request | |||||

Packing: | ||||||

standard export packing,wooden pallet | | |||||

Delivery Time | 20 days after receiving your depoist or original L/C | |||||

Minimum Order | 5 tons | |||||

The term of Payment | T/T, Irrevocable L/C at sight | |||||

Application | Mainly used in Construction , decoration,packaging, printing, cover material,piping, electronic elements, referigeration, air conditioner, automobile, and so on.

| |||||

Surface | Mill Finish or customizing for different clients | |||||

- Q: If not, where can i buy some aluminum?

- is your minuscule excuse for a dick a dick?

- Q: What are the different finishes available for aluminum sheets?

- Aluminum sheets offer a variety of finishes, each possessing unique characteristics and advantages. Some commonly used finishes include: 1. Mill finish: This is the most basic finish, giving aluminum sheets a smooth and shiny surface. It is achieved through the rolling mill process, maintaining the natural appearance. Mill finish is commonly preferred in industrial applications where aesthetics are not a primary concern. 2. Anodized finish: Anodizing involves an electrochemical process that adds an oxide layer to the aluminum sheet, enhancing durability and corrosion resistance. Anodized finishes can range from clear to various colors, and can be dyed to achieve specific shades. 3. Brushed finish: By brushing the aluminum sheet with abrasive materials, a pattern of fine lines is created on the surface, resulting in a distinctive textured appearance. Brushed finishes are often used in architectural and decorative applications. 4. Polished finish: Polishing aluminum sheets involves buffing the surface to a high shine, producing a mirror-like, reflective finish. This finish is commonly chosen for decorative purposes, such as in interior design, automotive detailing, or jewelry making. 5. Embossed finish: Embossing creates raised patterns or designs on the aluminum sheet, adding texture and visual interest. It can be achieved through roll embossing or stamping methods and is commonly used for decorative purposes or to enhance grip in certain applications. 6. Powder-coated finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat, resulting in a tough, durable, and visually appealing finish. Powder-coated finishes are available in a wide range of colors and offer excellent resistance to fading, chipping, and scratching. These are just a few examples of the diverse finishes available for aluminum sheets. The choice of finish will depend on the specific requirements of the application, including aesthetics, durability, and functionality.

- Q: Are aluminum sheets suitable for electrical enclosures?

- Yes, aluminum sheets are suitable for electrical enclosures. Aluminum is a lightweight and durable material that offers excellent electrical conductivity and corrosion resistance, making it an ideal choice for protecting electrical components. Additionally, aluminum's thermal conductivity helps dissipate heat generated by the enclosed equipment, ensuring proper functioning and longevity.

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- no that wouldn't make you sick. i line all my pans with foil before baking because it makes it much easier to clean the pans.

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: Can aluminum sheets be used for reflective insulation?

- Indeed, reflective insulation can make use of aluminum sheets. With their high reflectivity and impressive thermal conductivity, aluminum proves to be an exceptional option for effectively reflecting heat and minimizing heat transfer. By employing aluminum sheets as insulation, heat can be effectively redirected away from the surface, effectively preventing its entry or escape from the desired space. This proves to be advantageous in maintaining a cozy temperature indoors or safeguarding delicate equipment against extreme temperatures. Moreover, the lightweight nature and ease of installation of aluminum sheets further contribute to their popularity in reflective insulation applications.

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: How to carry out drawing process in aluminium plate

- The process of repeated scraping is an essential step in the production and processing, and we can not forget. The second is in the process of the film, to make the drawing processing after more shiny, look more beautiful, the film is the key technology in the field of production and processing. Should be careful, careful, can not be careless, such a careful and responsible work attitude, for drawing aluminum plate each place to do the details of the treatment, so that the filaments will be dense and bright.

- Q: Are aluminum sheets suitable for aircraft panels?

- Indeed, aircraft panels can be made from aluminum sheets. The aviation industry extensively employs aluminum due to its exceptional strength-to-weight ratio, rendering it an ideal choice for constructing aircraft structures that are both lightweight and robust. Aluminum sheets are frequently utilized for aircraft panels owing to their durability, resistance to corrosion, and ease of fabrication. Moreover, aluminum can be effortlessly molded and welded, enabling the creation of intricate panel shapes. Furthermore, aluminum possesses commendable electrical conductivity, a crucial factor in the efficient operation of diverse aircraft systems. In summary, the utilization of aluminum sheets for aircraft panels plays a pivotal role in ensuring the aircraft's structural integrity and performance.

Send your message to us

Light Gauge Embossed Aluminum Sheet and Coil Series 1/3/5/8 - Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords