Light Gauge Aluminum Sheets for Cookware - Continuous Casting Aluminum Coils Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

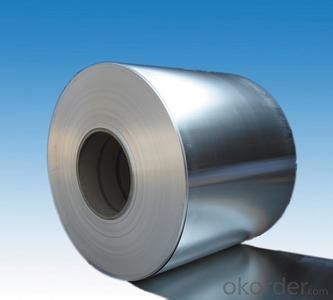

1.Structure of Continuous Casting Aluminium Coils for Cookware

Continuous Casting Aluminium Coils for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils for Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: What are the different types of finishes used for decorative aluminum sheet?

- There are several different types of finishes that can be used for decorative aluminum sheet to enhance its appearance and provide added protection. Some of the most common finishes include: 1. Mill finish: This is the standard finish that aluminum sheets have when they come straight from the mill. It has a smooth, shiny appearance but lacks any additional treatments or coatings. 2. Anodized finish: This finish involves an electrochemical process that creates a durable, corrosion-resistant layer on the surface of the aluminum. Anodized finishes can be clear or colored, and they provide a decorative, matte appearance. 3. Brushed finish: Also known as satin finish, this type of finish involves brushing the aluminum sheet with a fine abrasive material to create a pattern of fine lines or scratches. It gives the sheet a textured, non-reflective surface that hides any imperfections. 4. Polished finish: This finish involves polishing the aluminum sheet with a series of abrasive materials to create a smooth, reflective surface. It gives the sheet a shiny, mirror-like appearance and is often used for decorative purposes. 5. Painted finish: Aluminum sheets can also be painted with various types of coatings to provide different colors and finishes. These coatings can be applied through techniques such as powder coating, liquid painting, or coil coating, and they offer both decorative and protective benefits. 6. Embossed finish: In this type of finish, the aluminum sheet is pressed with a pattern or design to create a three-dimensional surface. Embossed finishes can vary in depth and detail, and they add texture and visual interest to the sheet. These are just a few examples of the different types of finishes used for decorative aluminum sheet. Each finish offers its own unique look and benefits, allowing for a wide range of design possibilities.

- Q: Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry. Aluminum is a lightweight and durable material that offers several advantages in automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, and other structural components. The use of aluminum sheets in automobiles helps to reduce the weight of the vehicle, enhancing fuel efficiency and improving performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for vehicles exposed to harsh weather conditions. Furthermore, aluminum sheets can be easily formed, welded, and joined, making them versatile and suitable for various automotive applications. Overall, the automotive industry widely embraces the use of aluminum sheets due to their numerous benefits.

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: bending, bending phenomenon will occur, I would like to annealing treatment. Does the master know the annealing temperature and time?

- And the same direction in the rolling, more than 1.5 of the thickness of cracking is more serious; it is proposed to increase the bending angle of R, annealing may not be solved.Or on the bending line and calendering line to cross 45 degrees (comparison fee)

- Q: What are the cost considerations when purchasing aluminum sheets?

- There are various factors to keep in mind when buying aluminum sheets that affect their cost. Firstly, the price of aluminum sheets is determined by the current market conditions. Factors such as supply and demand, global economic conditions, and geopolitical events influence the price. Therefore, it is important to stay updated on market trends and fluctuations to ensure an informed purchasing decision. Another consideration is the quantity of aluminum sheets needed. Buying in bulk or larger quantities often results in lower costs per unit. However, it is crucial to accurately assess the required quantity to avoid excess inventory and unnecessary expenses. Additionally, the grade and quality of aluminum sheets can impact their price. Aluminum sheets come in various grades, each with specific properties and performance characteristics. Higher-grade aluminum sheets, which have superior strength or corrosion resistance, tend to be more expensive. It is important to evaluate the project's specific requirements to determine the appropriate grade of aluminum sheets needed. Transportation costs should also be taken into account. Depending on the supplier's location and the quantity ordered, shipping expenses can vary significantly. Exploring different shipping options and negotiating favorable terms can help minimize transportation costs. Lastly, additional costs such as processing, finishing, and customization should be considered. Some projects may require services like cutting, bending, or coating the aluminum sheets, which can add to the overall cost. However, these services may be necessary to meet specific project requirements. In conclusion, it is crucial to consider the current market price, required quantity, grade and quality, transportation costs, and any additional processing or customization needs when purchasing aluminum sheets. By carefully evaluating these factors, one can make an informed decision and ensure the best value for their investment.

Send your message to us

Light Gauge Aluminum Sheets for Cookware - Continuous Casting Aluminum Coils Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords