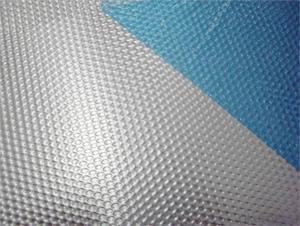

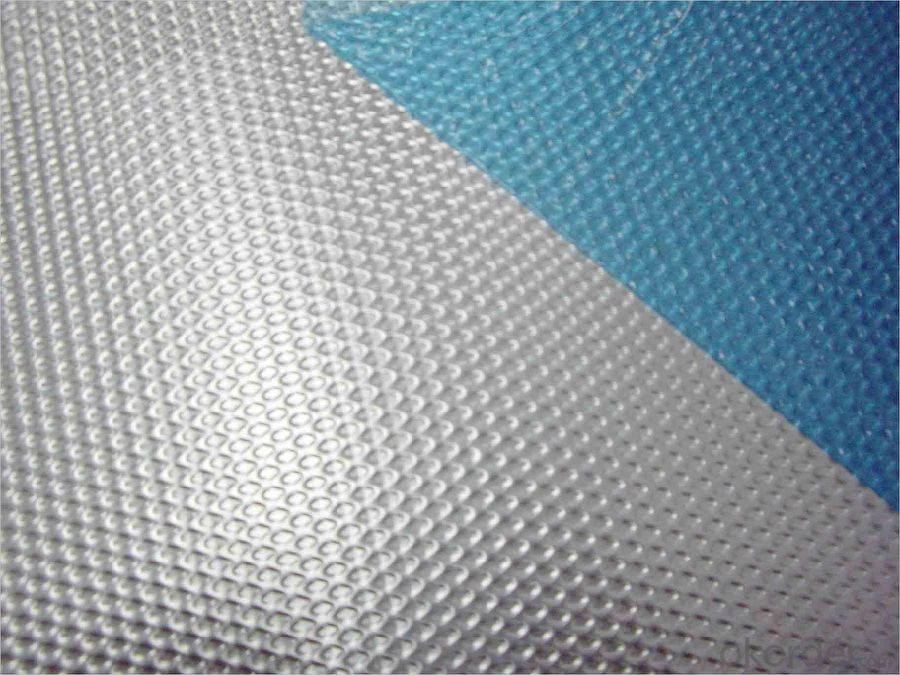

Embossed Aluminum Decking Sheets Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Stucco Embossed Coated Aluminium Coil

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-1.50mm |

Width: | 10mm- 1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2 Usage/Applications of Aluminum Can Stock(Body)

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

3 Packaging & Delivery of Coated Aluminium Coil/Sheet

Packaging: Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

- Q: What are the different types of surface treatments for aluminum sheets in the marine industry?

- Aluminum sheets are extensively utilized in the marine industry due to their lightweight nature and resistance to corrosion. To enhance their durability and performance in marine environments, various surface treatments are employed. These treatments provide an added layer of protection against corrosion, oxidation, and other types of wear and tear. Several surface treatments are available for aluminum sheets in the marine industry. One common treatment is anodizing, which involves an electrochemical process that creates an oxide layer on the aluminum surface. This layer adds strength, improves corrosion resistance, and can be dyed for aesthetic purposes. Another method is powder coating, which enhances the appearance and durability of aluminum sheets. It involves applying a dry powder to the surface and heating it to create a protective coating. Powder coating offers excellent resistance against corrosion, UV rays, and scratches. Chromate conversion coating, also known as chemical film coating or chromating, is another surface treatment option. This process immerses the aluminum sheets in a solution containing chromate compounds, forming a thin layer of chromate conversion coating on the surface. This enhances corrosion resistance and provides a suitable base for subsequent painting or bonding. Paint coating is another surface treatment method in the marine industry. It not only enhances appearance but also protects against corrosion, saltwater, and harsh environmental conditions. Epoxy or polyurethane-based paints are commonly used for marine applications. Mechanical treatments, such as brushing, grinding, or polishing, can also be performed on aluminum sheets to improve their surface finish. These treatments remove impurities, smooth out imperfections, and enhance the overall appearance of the aluminum surface. Each surface treatment has its own advantages and is chosen based on the specific requirements of the marine application. By selecting the appropriate treatment, manufacturers can ensure that aluminum sheets meet the necessary performance and durability standards in the demanding marine industry.

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- Surface roughness plays a crucial role in the adhesion of coatings on aluminum sheet. The level of roughness on the surface of the sheet directly impacts the mechanical interlocking between the coating and the substrate, which is essential for strong adhesion. When the surface of the aluminum sheet is smooth, there is limited contact area between the coating and the substrate, resulting in weak adhesion. On the other hand, a rough surface provides more contact points, increasing the interlocking between the coating and the aluminum sheet, leading to improved adhesion strength. Additionally, a rough surface promotes better wetting of the coating material on the aluminum sheet. This means that the coating material can spread more easily over the surface, filling in any gaps or crevices, and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area means that there is more available space for the coating material to adhere to, increasing the adhesion strength. It is important to note that there is an optimum level of roughness for achieving the best adhesion. If the surface is excessively rough, it may lead to incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is crucial to ensure optimal adhesion of coatings on aluminum sheet.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: Can aluminum sheets be welded or soldered?

- Aluminum sheets have the capability to undergo both welding and soldering processes, although the techniques for each differ significantly. When welding aluminum, a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process is typically employed, necessitating a high heat source and a filler material to connect the sheets. This process is generally more demanding when compared to welding steel due to aluminum's high thermal conductivity and lower melting point. On the other hand, soldering aluminum involves utilizing a low-temperature solder and flux to bond the sheets together. Usually, specialized solders like aluminum solder or solder with a high tin percentage are employed. Soldering aluminum is typically less prevalent and more intricate than soldering other metals due to the presence of an oxide layer on aluminum, which hinders proper adhesion. To summarize, while both welding and soldering can be utilized for joining aluminum sheets, welding is the more commonly employed method due to its superior strength and durability. Soldering aluminum presents additional challenges due to the requirement for specialized solders and the presence of the oxide layer.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets do not possess notable electrical insulation properties. Being a highly conductive metal, aluminum enables the easy flow of electric current. Consequently, effective electrical insulation cannot be attained with aluminum sheets. In situations where electrical insulation is necessary, alternative materials like plastics or ceramics would be more appropriate choices.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

- Q: What are the different types of alloys used in aluminum sheets?

- There are several different types of alloys used in aluminum sheets, each offering unique properties and benefits. Some of the most common alloys include: 1. 3003 alloy: This alloy is commonly used in general-purpose applications due to its excellent formability, corrosion resistance, and weldability. It is often used for cooking utensils, signage, and chemical equipment. 2. 5052 alloy: Known for its high strength and good corrosion resistance, the 5052 alloy is commonly used in marine and automotive applications. It is also used for sheet metal fabrication and structural components. 3. 6061 alloy: This alloy is highly versatile and is used in a wide range of applications, including aerospace, automotive, and structural components. It offers excellent strength, machinability, and weldability. 4. 7075 alloy: Primarily used in aerospace and high-strength applications, the 7075 alloy is known for its exceptional strength-to-weight ratio. It is often used in aircraft fittings, gears, and bike frames. 5. 2024 alloy: Another popular alloy in aerospace applications, the 2024 alloy boasts a high strength-to-weight ratio and excellent fatigue resistance. It is commonly used for aircraft structures, bolts, and rivets. 6. 5083 alloy: This alloy is specifically designed for marine applications due to its outstanding corrosion resistance and high strength. It is often used for boat hulls and structural components. These are just a few examples of the various alloys used in aluminum sheets. Each alloy has its own unique combination of properties, allowing it to excel in specific applications.

Send your message to us

Embossed Aluminum Decking Sheets Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords