Homemade Dryer Sheets Aluminum Foil Coated Alloy Aluminum Coil/Sheet Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

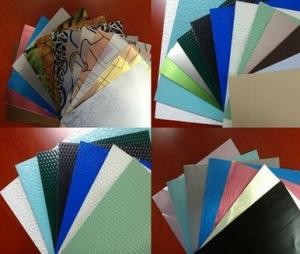

1 Specifications of Coated Aluminum Coil/Sheet

| Original Price | LME + USD1580/mt |

| Current Price | LME + USD1300/mt |

| Alloy | AA3000, AA5000 |

| Temper: | H00, O/F |

| Thickness: | 0.03mm-3.0mm |

| Width | 30mm-1700mm |

| Paint | PE, PVDF, Epoxy |

| Color | According to Ral colors or customer's samples |

| Special Specification is available on customer’s requirement | |

2 Usage/Applications of Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

3 Packaging & Delivery of Coated Aluminium Coil/Sheet

Packaging: Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: the goods will be delivered within 40 days after getting the buyer's payment.

4 Production Flow of Coated Aluminium Coil/Sheet

- Q: Are aluminum sheets suitable for use in automotive or aerospace industries?

- Yes, aluminum sheets are suitable for use in both the automotive and aerospace industries. Aluminum is widely used in these industries due to its lightweight yet strong properties, corrosion resistance, and good thermal and electrical conductivity. It is commonly used in the construction of vehicle bodies, aircraft frames, and various aerospace components.

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The optical properties of aluminum sheet are significantly influenced by its surface finish. Optimal light reflection and minimal scattering are achieved with a smooth surface finish, leading to heightened reflectivity. Consequently, this amplifies the brightness and reflectiveness of the aluminum sheet. Conversely, a rough or textured surface finish on aluminum sheet provokes light scattering in various directions, thereby diminishing reflectivity. Consequently, this yields a lackluster and less reflective appearance. Furthermore, the surface finish has an impact on the visual aspect of any coatings or films applied to the aluminum sheet. A smooth surface finish promotes superior adhesion and uniformity of coatings, thus augmenting their optical properties. To conclude, the optical properties of aluminum sheet are improved with a smooth surface finish, as it enhances reflectivity and diminishes scattering, ultimately resulting in a more vibrant and reflective appearance.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that adds a protective oxide layer to the surface of aluminum, enhancing its durability and corrosion resistance. During the anodizing process, the aluminum sheet is immersed in an electrolytic solution and an electrical current is passed through it. This causes a controlled oxidation of the aluminum surface, creating a porous layer that can be dyed to achieve custom colors. By carefully selecting the dye, different shades and hues can be achieved, allowing for a wide range of custom color options. Additionally, anodized aluminum sheets can also be further processed with techniques such as laser engraving or printing to create unique designs and patterns, making them a versatile choice for various applications in industries like architecture, automotive, and electronics.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- This Site Might Help You. RE: Aluminum Vs. Fiberglass Ladders? I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- Q: I think I remember that this is true of aluminum foil. When it's charged, it'll push away from itself, I know. Why do magnets have seemingly no effect?

- Aluminum is a non-ferrous metal. Ferrous metals contain Iron which is magnetic. When aluminum has a charge applied to it, it acts like any conductor would, the charge has magnetic properties. the aluminum is still not magnetic, but it acts like a magnet due to the charge.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Brother, I want to tell you first, the aluminum grinding machine is very rare! Because the aluminum sticky grinding wheel!No money, people are: 1., flying base level, thickness to 26.5 low point! 2. turn the face, press 4 sides, drill rough. The 3. lock bolt is in the hole you hit! Notice here that the lock must be locked one by one! Do you think the workpiece completely tied to lock dead in the fixture, and then processing the thickness to 25.6, the Kong Xian crude drilling reamer locking bolt end processing in place, lock 4. replacement bolts, the original lock bolt hole processing in place! 5., the final flying surface, according to each side of the 0.3 to fly surface, flying surface fixed method, you can use hot melt adhesive or hard rubber mud to fix the workpiece 4 sides and forming the inner hole!The rich person is the vacuum sucker, the base level as much as 26.5, turn over the surface of the vacuum sucker, forming directly!Hope to adopt, typing hard enough!

- Q: Can the aluminum sheets be custom-cut to specific dimensions?

- Yes, the aluminum sheets can be custom-cut to specific dimensions.

Send your message to us

Homemade Dryer Sheets Aluminum Foil Coated Alloy Aluminum Coil/Sheet Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords