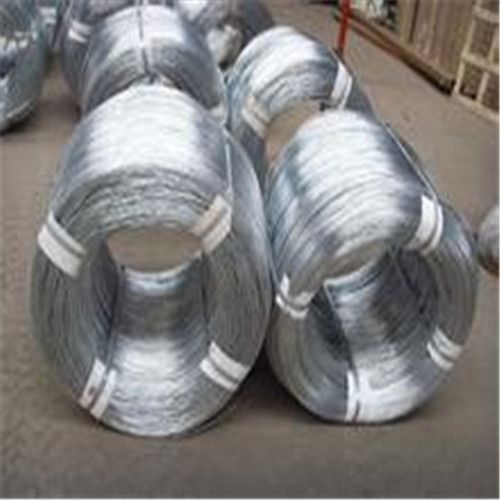

Electro Galvanised Iron Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Wire /Galvanised Steel Wire

(1) Quality : Meet GB/T 343 standard and other requirements of relevant standards .

(2) Zinc Coating: Meet GB/T 15393 standard and other requirements of relevant standards .

(3) Raw Material : Wire rod ——1006 , 1008 , 1018 , Q195 , etc, and zinc with 99.995% purity.

(4) Tensile Strength Range

Size (mm) | Tensile Strength (mpa) |

0.15-1.60 | 290-550 |

0.65-1.60 | 400-550 |

1.61-6.00 | 400-1200 |

(5) Application : Used in wire mesh , artware , metal hose , binding for agriculture and construction , etc.

(6) Packing

Size (mm) | Coil Size | Spool Packing | Big Coil Packing | |

ID (mm) | OD (mm) | |||

0.15-0.26 | 6 inch | 1-14kg/spool |

|

|

0.27-0.60 | 8 inch | 1-100kg/spool |

|

|

0.61-1.60 | 12/14/16 inch | 1-100kg/spool | 250-400 | 400-770 |

1.61-6.00 |

| 14-500kg/spool | 450 | 800 |

508 | 840 | |||

(7) Zinc Coating

Meet GB/T 15393 standard.

Size (mm) | Weight of Zinc-Coating ( g/m2 ) | |||||||

A | AB | B | C | D | E | F | ||

A1 | B2 |

|

|

|

|

|

| |

≤0.25 |

|

| 30 | 20 | 18 |

|

|

|

>0.25-0.40 |

|

|

| 30 | 25 | 20 |

|

|

>0.40-0.50 |

|

|

|

| 30 | 20 |

|

|

>0.50-0.60 |

|

|

|

| 35 | 20 |

|

|

>0.60-0.80 | 120 | 110 |

|

| 40 | 20 |

|

|

>0.80-1.00 | 150 | 130 |

|

| 45 | 25 |

|

|

>1.00-1.20 | 180 | 150 |

|

| 50 | 25 |

|

|

>1.20-1.40 | 200 | 160 |

|

| 50 | 25 |

|

|

>1.40-1.60 | 220 | 180 |

|

| 50 | 35 | 30 |

|

>1.60-1.80 | 220 | 180 |

|

| 70 | 40 | 30 |

|

>1.80-2.20 | 230 | 200 |

|

| 80 | 50 | 40 |

|

>2.20-2.50 | 240 | 210 |

|

| 80 | 55 | 40 |

|

>2.50-3.00 | 250 | 230 |

|

| 90 | 70 | 45 |

|

>3.00-4.00 | 270 | 250 |

|

| 100 | 85 | 60 | 30 |

>4.00-5.20 | 290 | 270 |

|

| 110 | 95 | 70 | 40 |

>5.20-6.00 | 290 | 270 | 245 |

| 110 | 100 | 80 | 50 |

- Q: How is commercial wiring differ from residental wiring in design,operation and etc?

- This Site Might Help You. RE: Residental Vs Commercial Electric Wiring? How is commercial wiring differ from residental wiring in design,operation and etc?

- Q: Am I able to do this? The wire burn the clay?

- If you are referring to using a metal armature inside Sculpty, then No it will not burn the clay. You do need to follow the baking instructions though. It will bake just fine and you will be surprised how strong the sculpture is after baking.

- Q: My house is wired for surround sound. The wires coming out of the speakers holes are not labeled as far as i can tell but the wires that are coming out of housing that go into the back of the receiver are labeled 26,27,30,and 31. I cant tell which wires go to which speaker Front Left, Front Right, Rear left or Rear Right. Do these numbers mean anything?

- No. It should not be too hard to try hooking on speaker up at a time though and finding what runs to what. Then writing it down. Did the previous owner have a package of documenttion to pass on to you?

- Q: I spliced the stereo wires to the adapter to plug into my car. there's 2 extra orange wires in the adapter. There orange it says there for illumination and the dimmer. What should I do with them? Did I get the wrong one?

- If the vehicle/truck grew to become into made until now 1968 i'm able to warm cord it andchronic it.After 1968 i'm able to attempt initiate the engines yet i cannotchronic it now devoid of disassembling the steerage wheel calum.somebody advised me,then your no longer e very stable mechanic.I replayed no that advise i'm no longer a vehicle thief.

- Q: my dogs have chewed my central air contactor wire.my ac will not cut on. does anyone knows how to replace them and where to buy replacement wires locally( i live in Dallas TX.) i would like to do it myself instead of spending a lot of money.

- You shouldn't need to replace the wires, only splice them back together, color to like color. If you decide to replace them, they are 18 gauge. Depending on the unit that you have, there may be 2, 3, 5, 7, or 9 wires. Install the wire in 3/8 flex to prevent a repeat. Lowes and Home Depot will sell you the wire by the lenght you need. Ask for jacketed wire.

- Q: How can I investigate the resistance of wire and how it changes with the length of the wireCheers

- get a multimeter. get long lengths of different gauge (diameter) copper lead wire. for each diameter, measure the resistance. cut 1ft off, measure the resistance, cut 1ft off, measure the resistance, cut 1ft off, etc etc. plot the resistance vs length for each gauge separately. show that the resistance is linear in the wire length in each case. now use the different diameter data to measure the resisitivity of copper. resisitivity rho = R*A/L R = resistance L = length A = cross-sectional area cheers

- Q: there is different gauge wire sizes in the power/ground and speaker wire? which is better? what is the difference? buy ground power and speaker wire the same gauge?

- Use the 4 gauge wire (thicker) for your power and then the 8 gauge wire for speakers and ground. If you are wiring a stereo with an amp, its best to ground both at the same spot to reduce what is called ground loop. Otherwise, you may hear engine noise through your speakers and possibly clicks when using your turn signals.

- Q: It every download on lime-wire basic free and is the down load of lime-wire basic free is lime wire really illegal thanks

- Lime Wire is LEGAL.. just not the illegal content you download on it. Also, just because somebody buys LimeWire Pro doesn't mean it is legal to download songs.. The chance of getting caught is low though, so I wouldn't worry about it.

- Q: Does anyone know what color the amp sensor wire is on a 2005 EX?

- some amp's have an auto power on when they receive a signal through the input speaker wires. that would give them a power and ground wire only.

- Q: Okay so bought 2 Kicker Comp C12-8 subs they are single voice coil, and I bought the Kicker DX300.2 amp. I would like to parallel wire thes subs to have a 4 ohm load, But I don't totally get the concept of it. Could somebody explain it, or show me a diagram, or video, or something?

- Parallel: okorder /

Send your message to us

Electro Galvanised Iron Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords