Single Screw Recycling Machine for Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Screw Recycling Machine for Pipe

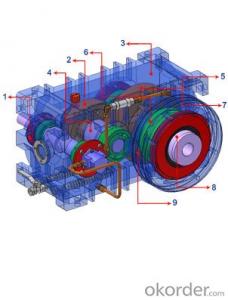

Description of High Quality Extruder

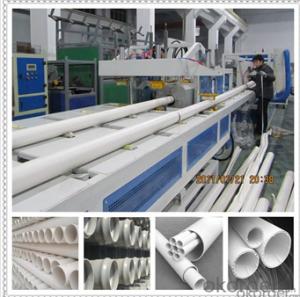

Single Screw Recycling Machine for Pipe is mainly used to process PP, PE, PPR,ABS and other plastics. Equipped with auxiliary machines, it can manufacture profile, pipes, sheets and other plastic products and granulation. This Single Screw Extruder has the advantage of simple production technological process, high output, stable quality and low cost.

Advantages of High Quality Extruder

1.Suitable for various polyolefin materials: PVC, PC,and ABS etc. single screw extruder adopts advanced human-machine interface control system to realize the automatic control of the whole line

2.Excellent temperature control system to ensure the stability of the producing process. Integrated design of force water cooling and force feeding groove ensures the evenness and stability of the manufacturing process.

3.High-performance driving system; Wearable and easy to maintain.

Technical Parameters of Sigle Screw Extruder

Model | L/D | Output (kg/h) | Speed of Screw Rotation (r/min) | Power (kw) | Center Height (mm) |

JWS45 | 25/28 | 25/30/38 | 10-100 | 11/15/18.5 | 45 |

JWS65 | 25/28 | 50/60/80 | 10-100 | 18.5/22/30 | 65 |

JWS75 | 25/28 | 80 | 10-100 | 37 | 75 |

JWS80 | 28/30 | 100 | 10-90 | 37 | 80 |

JWS90 | 28/30 | 120 | 10-90 | 45 | 90 |

JWS120 | 28/30 | 250 | 10-90 | 75 | 120 |

Idea

The design concept of low temperature plasticization, ensure the high quality products of extrusion.

The two order integral design, strengthening plasticizing function, ensure the adjustment of high-performance extrusion.

The special barrier, comprehensive mixing design, to ensure the effect of mixing material.

The high torque output, large thrust bearing.

The gear, shaft for high strength alloy steel, carburizing, tooth grinding processing.

The high hardness, high smoothness, ultra low noise.

The PLC intelligent control, can realize the linkage between the main and auxiliary engine.

Excellent monitoring human-machine interface, easy to understand processing and machine status.

You can be replaced according to requirements of control mode (temperature control instrument).

The material for the 38CrMoAL/A nitriding, wear resistance.

The accuracy of temperature control strictly, wind cooling combined cooling.

The material inlet design unique, perfect with water cooling device.

Screw cylinder with bottom sleeve groove surface feeding, with enhanced feeding function, provide guarantee for high-speed high-yield extrusion.

- Q: What are the machinery needed for plastic processing?

- Extruder is the role of the screw in the molten plastic through a fixed shape of the extrusion port extrusion, under the action of the tractor after the water-cooled after cutting. Mainly used for a variety of the same cross-section of a large number of continuous production, such as tube

- Q: Plastic products manufacturing machinery parts company which?

- Changzhou Hongyi German Plastic Machinery Manufacturing Co., Ltd

Send your message to us

Single Screw Recycling Machine for Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords