Diamond Plate Polished Aluminum Alloy Sheets for Metal Walls 4x8x1/4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Polished Aluminum Alloy Sheets for Metal Walls

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Polished Aluminum Alloy Sheets for Metal Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Polished Aluminum Alloy Sheets for Metal Walls

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

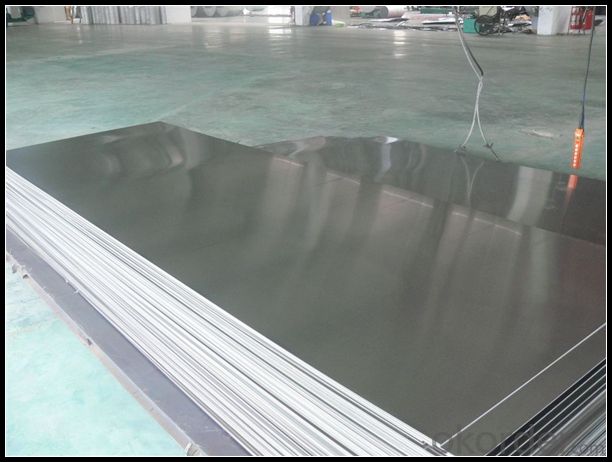

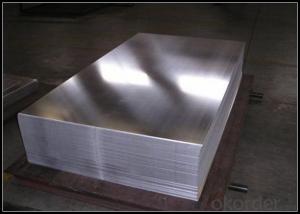

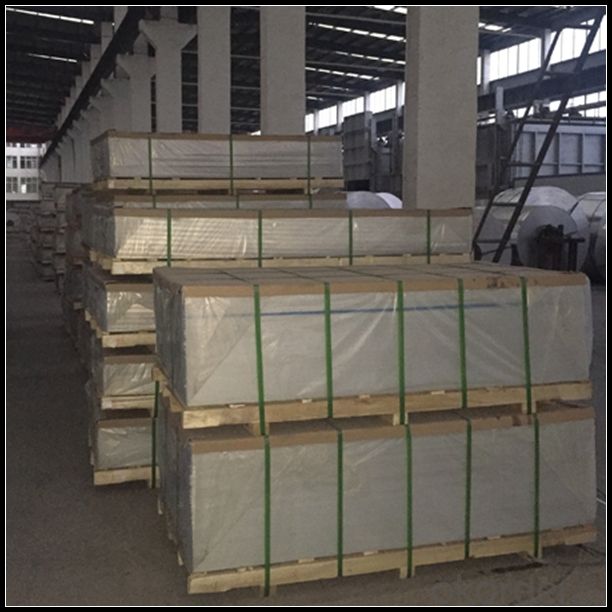

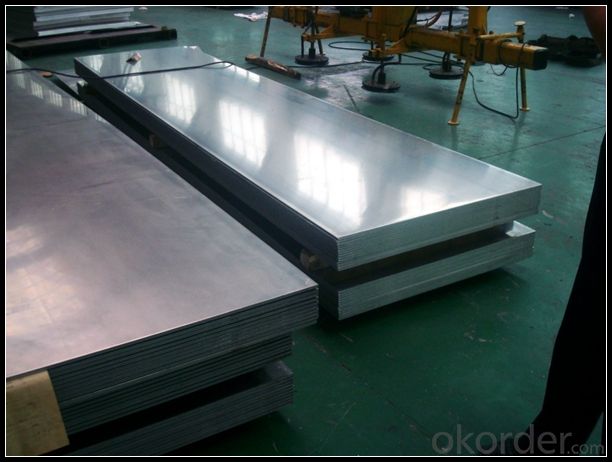

5. Image of Polished Aluminum Alloy Sheets for Metal Walls

6. Package and shipping of Polished Aluminum Alloy Sheets for Metal Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- Aluminum and titanium are lighter, but they are easier to scratch (due to non-stick coatings) and do not hold heat as well. Stainless steel is more durable and distributes heat better. You can also clean it with sand or ice without having to worry about scratching it. If you are going to fry with it, you will need oil since the food will stick without it. When I go ultra light, I use a jet boil with a titanium pot to boil water for cooking. When I want to go gourmet, I use the GSI stainless steel set.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- This is not my expertise. As I have been researching this the past hour to re-educate myself, no one else has answered you. So, I will attempt to get you in the right direction by what I found. I found two specific heat values for Aluminum. The recent one is from wikipedia with the other an old text someone quoted. The specific heat of aluminum, cAl, is 0.897J g?1 K?1; this is, 0.214cal g?1 °C?1. [per wikipedia] AND The specific heat capacity of aluminum as 0.215 kcal/(kg C) [The Handbook of Chemistry and Physics, p. D-217, 1979]. Standard Value was the harder item. I found it is referred to as Hro [Where the o is a circle]. I could only find it referring to water. To measure heat for each metal, it was always compared to the heating water, which is used as the standard. I'm guessing its like a thermometer filled with mercury. The mercury gets heated and the lines are marked to tell you how hot the air is. Hope that helps... Maybe someone else will jump in...

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are highly suitable for manufacturing kitchen utensils. Aluminum is a lightweight and durable material that offers excellent heat distribution properties. It is corrosion-resistant, making it ideal for contact with food and liquids. Additionally, aluminum is non-reactive, which means it does not leach any harmful substances into the food being cooked or stored. It is also easy to clean and maintain, making it a popular choice for kitchen utensils. Overall, aluminum sheets are a reliable and efficient option for manufacturing a wide range of kitchen utensils.

- Q: Explain the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with several options to enhance their appearance, durability, and functionality. These include: 1) Anodizing, which creates a protective oxide layer, 2) Powder coating, offering a wide range of colors and textures, 3) Liquid painting, for a smooth, painted finish, 4) Laminating, which bonds a protective film to the surface, 5) Electrolytic coloring, resulting in a variety of colors, 6) PVD (Physical Vapor Deposition), for a high-quality, durable finish, and 7) Thermal spraying, applying a coating to improve wear resistance. Each method serves different purposes and has its advantages and limitations.</p>

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets are suitable for storage tanks.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets are highly sought after in various industries due to their unique mechanical properties. To begin with, they possess an exceptional strength-to-weight ratio, making them both lightweight and strong. This quality is particularly valuable in industries like aerospace and automotive, where reducing weight is crucial. Furthermore, aluminum sheets are highly malleable, allowing them to be easily shaped and formed into different sizes and configurations. This versatility makes them ideal for applications that require complex shapes, such as the manufacturing of cans, appliances, and architectural components. In addition, aluminum sheets have a high resistance to corrosion, thanks to the development of a thin, protective oxide layer on their surface. This durability makes them suitable for outdoor applications or environments with high moisture or chemical exposure. Moreover, aluminum sheets exhibit excellent thermal conductivity, enabling them to efficiently transfer heat. This property makes them widely used in heat exchangers, cooling systems, and other applications where effective heat dissipation is necessary. Lastly, aluminum sheets possess good electrical conductivity, allowing them to effectively conduct electricity. This makes them suitable for electrical enclosures, conductors, and other electrical applications. To summarize, the mechanical properties of aluminum sheets include a high strength-to-weight ratio, good formability, high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. These properties make aluminum sheets the preferred choice for a wide range of applications across various industries.

Send your message to us

Diamond Plate Polished Aluminum Alloy Sheets for Metal Walls 4x8x1/4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords