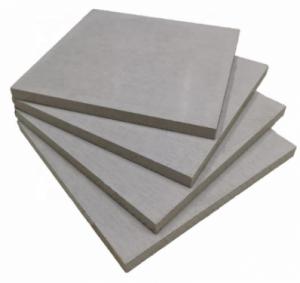

Decorative material top quality fiber cement board price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brand Name:CMAX

Density:More than 1.2g/cm3

Application:Ceiling ,Wall panel, Floor, partition

Specification:2440*1220mm(Length*Width)

Thickness:6/7/8/9/10/12/18/25 mm

Advantage:Easy-installing, Eco friendly

Incombustibility:GB8624-1997 Grade A1

Bending Strength:12Mpa

Type:Fiber Cement Boards

Supply Ability:10000 Piece/Pieces per Day

Packaging & Delivery

Packaging Details

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Port:Guangzhou or Foshan Port

Specification

1. Small board: 595*595mm /600*600mm /603*603mm /595*1195mm /600*1200mm

2. Big board: 1220*2440mm /1220*3050mm

3. Thickness: 4.5, 5, 6, 8, 10, 12, 15, 18, 20, 25mm (4.5-30mm)

Remark: Other specification is available.

Application

application: Partition wall and ceiling

Fireproof structure: Fire Rating Partition, Ceiling, wall, door,

Exterior Cladding and façade structure

Sound Insulation structure

Usage in wet areas

Other purpose: applied to furniture, interlayer floor, interior substrate

Technical Data

Item | Index | Unit | ||

Density | ≤1.20 | g/cm3 | ||

Water contain | ≤10 | % | ||

Water absorption | ≤39 | % | ||

Incombustibility | Grade A1 incombustible | |||

Bending strength | Oven dry | cross | ≥12 | M pa |

Parallel | ≥10 | M pa | ||

Fiber Cement Board With Factory Low Price

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

Packaging Details:

Fumigation wooden pallets+PE cover + corner protector

- Q: What do you use under the tiles, and do you still use grout as well?

- Normally you install tiles over a concrete slab using modified thinset for exterior use. Regards, Dale

- Q: What is the weight of the generally insulated panels? As much as possible to list some, thank you prawn

- Now talk about the shortcomings of high-density cement fiber board products, the biggest deformation, deformation is a major feature of this product, especially high-density cement board deformation is very large, this product is not suitable for large-scale external walls, not suitable for large area for Wall, after years of product research and customer reflection to prove this point.

- Q: Will the cement board on the decoration be used to blow it directly?

- If the wall can be placed directly putty putty, putty on the general scraping three times; if the wall is not flat on the first use of plaster gypsum leveling, and then scraping putty.

- Q: What are the fiberboard specifications? Fiber cement board thick

- According to industry standards JC / T412.2--2006, fiber cement board is the industry's formal name, the domestic commonly used is 1200 * 2400mm * 4 - 30mm

- Q: Outdoor use of cement pressure plate can not

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials.

- Q: Home studio decoration, do noise wall, is the effect of good gypsum board or cement fiber pressure plate effect is good

- Sound insulation generally follow the law of quality that the greater the density of the better sound insulation. 12mm paper gypsum board surface density of about 8.8kg / ㎡, the average volume of 25dB; 9mm fiber cement pressure plate (FC board) surface density of about 6kg / ㎡, the average volume of 30dB; In summary, the cement pressure Board sound insulation effect is higher than the paper gypsum board.

- Q: Gypsm plaster is recommended in Christopher Alexander's Pattern Language (#235 Soft Inside Walls) If I were to go to a building supply store and ask for gypsum plaster would they know what I was talking about? ...Is it a universal term? Can you give me a chemical formula?

- Gypsm is hydradated pulverized limestone. You would ask for Gypsym topcoat or Gypsm tape adhesive in the Drywall department of Lowes. It costs today $9.95 for a 5 gallon pail of the stuff. Gypsm is resoluable in water after drying. In other words you can redissolve gypsm in water. Gypsm is mined in the US in states like Michigan, Indiana, Ohio and so on. It is a naturally occuring substance. Plaster of Paris is unhydrated form of lime. When wetted with water it changes chemically and remains hard no matter if submerged into water. The process is irreversible. Cement is made from clay and limestone fired to high temperatures, then ground and pulverized. When water is added to cement it changes its chemistry and the water reacts with cement forming a new compound It is irreversible The Romans invented Cement. Common Drywall is gypsm between 2 layers of paper enclosure. There are also metal lath in 26x84 inch lenghts and plaster board lath in 16x36 inch lengths Those all above are nailed or glued to the house studs.

- Q: We are going to remove the vinyl flooring. It has a 1/4in sub floor over hardwood.

- Are you saying hardwood and not the ply wood sub floor? You can t go over hard wood with tile, even with a backer board.There is to much movement and expansion and contraction . Must remove this too. Now if you mean sub floor then yes it s very important that you do cement board ( 1/2) you need this total thickness in substrate to meet tile codes 1 1/4 minimum.This must be layed properly in a bed a thin set and nail well. Any other questions you can e mail me thru my avatar and check my qualifications there GL

- Q: I am planning on doing cement around bath and shower in my home. i already have cement backer board up and wire mesh screening. what do i use to make it not crack and smooth and what material do i use

- You're welcome to do whatever you want, but concrete is porous like grout. Ever seen nasty grout? Even sealed grout gets disgusting without proper maintenance (ie squeegee) and cleaning. Imagine that all over the wall. Even if you make it ultra smooth and seal it my guess is that this would get disgusting in a hurry...unless you happen to have a power washer in your bathroom... ;)

- Q: What is the best fixation screw in the cement board?

- With AB glue, vigorously glue These two kinds of glue is a strong adhesive, durable adhesive

Send your message to us

Decorative material top quality fiber cement board price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords