Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

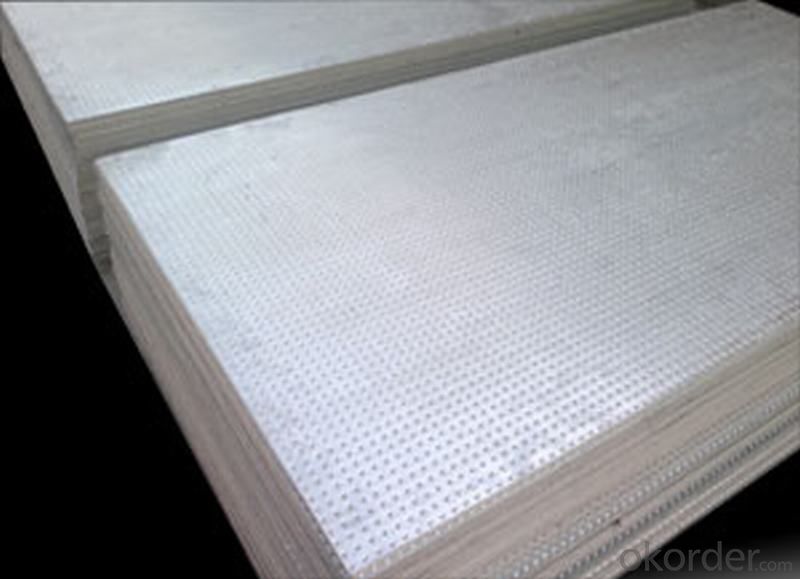

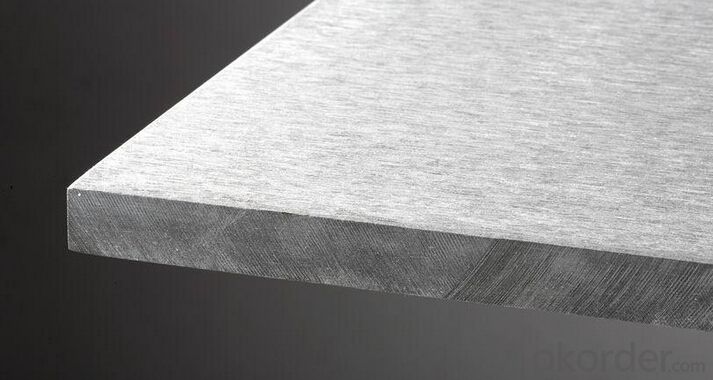

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of hightech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Incombustibility: It can not burn and give off toxic smoke.

2) Heat insulation: Low heat conductivity, good thermal insulation.

3) Waterproof: It can keep its shape without swelling and deformation after a long time.

4) Sound proof: Reduce indoor noise.

5) Environmental protection: high density reinforced fiber cement board `s special characters make more comfortable environment.

6) High Strength: High-stength and impact-resistant make it is not easy to be damaged.

7) Durability: insulation against bugs, fungus and corrosion,so reinforced fiber cement board can last for a long time.

8) Easy installation: Painting, tiling and nailing can be feasible in the new system.

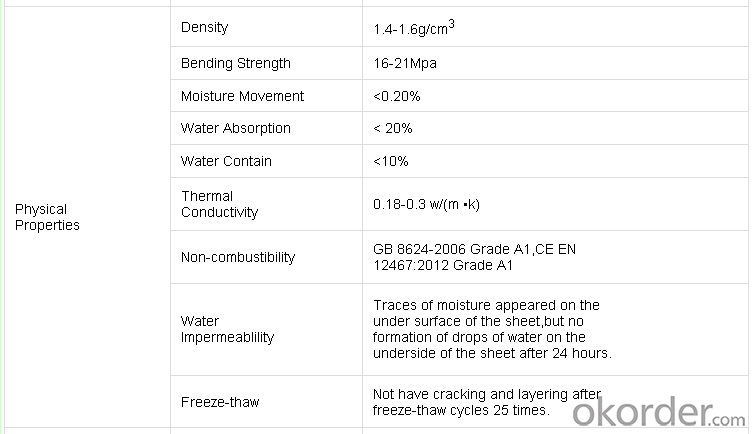

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: How to put tiles on the cement board

- In the partition on the tile is generally the most common is: first need to paste the tiles with a grid (0.5X0.5) with 30 straight row nail fixed, so after a thin layer of cement on its bottom (select Thinner because when you have finished the wall after the finished tile thickness of about 4CM, if your bottom is too thick; in the passage of time there will be cracks, which is the overall wall in the wall caused by the top of the pull. So it is thin) and so on when it can quickly paste through the dry.

- Q: And the best way to attach it to a wood frame.

- any carbide tipped saw blade circular saw or jig saw the jig saw blade costs less clamp on a guide to make straight cuts. special screws that go into the floor at least a 1/2 or more. the floor must be flat and solid or you tiles or grout will crack. use self lever to make floor flat if it is not.

- Q: Do not you dry the stone

- Yes, as long as the cement surface to ensure the smoothness of the surface roughness and verticality can be directly sprayed.

- Q: I would like to build 4 steps on a incline. It is above a retaining wall but will be a good foot away from the wall all on firm packed dirt. I have a couple questions. One side of the steps would be next to the garage wall.1. Can I pour cement up against the cinder wall?2. If so how would someone build steps form without any boards against the one side. So basically just have the one side and front plate.3. Or would you recommend having a board against the wall. Or pull it out after the form has set?

- have you thought of buying a precast fiberglass step, they go well with weather, they are strong and you can pain them if you like. Home Depot might have some

- Q: over the bath tub is durock cement board enough by itself,or it has to be something else under durock...?

- If the tub wall is on an outside wall it should be insulated & then sealed with plastic, then durock, then the tile. For sound purposes you can insulate the other walls also.

- Q: I just completely gutted my bathroom down to the wall studs and original plywood sub-floor. Which do I install first -- the new bathtub or the cement backer board on the floor? The original tile floor was over an inch thick. The new tub will be fiberglass, and I plan to put ceramic tile around the tub area as well as the main floor.

- If you got the standard enamelled metal tub you will see that the top edge may have screw holes already in it. I don't think fiberglass was much different- maybe no holes and you have to drill them yourself as the tub is in place This is screwed to the studs. Can't see studs behind cement board.(Don't care if you have better than 20:20 vision) CB is just a board for tiling onto. Before that was Greenboard basically gypsum board with a waterproof coating. Before that it was just gypsum board. The Tile& grout is the waterproof layer. Many houses were done on gypsum board. Mine has been done that way because neither Greenboard or Cementboard were not invented yet. Mine has been up for 35 years not a problem at all.

- Q: I have a 5x20 room off my basement which sits under my front porch. All four walls of the room are cement block all the way up to the ceiling which is the cement slab from the porch above. There is a wood ceiling in the room that has gotten wet from leaks above. Is it safe to remove the wood joists and plywood in that room, fix the leaks and replace it? This doesn't support any weight from the slab above, does it? I assume that it was probably used as the bottom of the form when the slab was poured. Also, when I replace the ceiling, can I attach the ledger board using concrete sleeve anchors? Can these be fastened into the block wall? I'm not sure if they are hollow or have been filled with gravel or concrete. I plan on using the ledger board to fasten joist hanger to and frame back up my ceiling for insulation and wiring. The current ledger is attached with masonry nails. Any thoughts?

- Your ceiling may very well be no more than the bottom forms for the slab, but you really need to make sure. Attempting to seal the concrete slab from the underside isn't advisable. Concrete draws moisture, so you will always have a seepage problem after you're finished. I'd suggest sealing the slab on the surface and make sure it quit weeping before proceeding with the remainder of your project. Not all concrete blocks are filled. To secure your ledger board I'd suggest using a lag bolt with a lead spread type toggle. Drill into the block and insert to lead, which will hold the lag bolt. Hope this has been some help. Good Luck

- Q: Its all gonna get covered with mortar anyway when I put the tile on, right? So.... Is it NECESSARY to mortar the joints before hand or not?

- If the top layer of plywood is treated then there is no reason whatsoever to apply water proofing. If it isn't treated then there is always a small risk that large amounts of mold could develop in the plywood, but it is a small risk. I would pull up the cement board and put roofing felt under it. Or if I didn't want to take the time for about 80 dollars I can pick up a spray on waterproofing layer to the cement board that most tile flooring stores should carry. Tile membranes are good product, but somewhat expensive to use. Grout is sealed to protect the integrity of the grout and no other reason. A small amount of floor movement and water will have a direct path past the grout.

- Q: Help? Do I just lay new thinset on top or what?

- That's what a friend and I did when we couldn't get the old thinset up off his kitchen floor. We just laid down some more thinset so the floor was level all the way across.

- Q: Bought new ceramic tile for kitchen and the old stuff is hard to get up. I want to keep the cement board that is in there for the new stuff.

- It's next to impossible to remove Ceramic with out damaging the cement board. Esp. if the tile was installed properly to begin with. Tile is installed with a thin-set type mortar when using a Cement backer. If installed over plywood they would have used a ceramic Mastic [glue] That can be removed much easier. You can however lay the new tile over the old, but this will raise the level of the floor, not a good idea when in the Kitchen.

Send your message to us

Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords