Fiber Cement Board for Interior a nd Exterior Walls

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

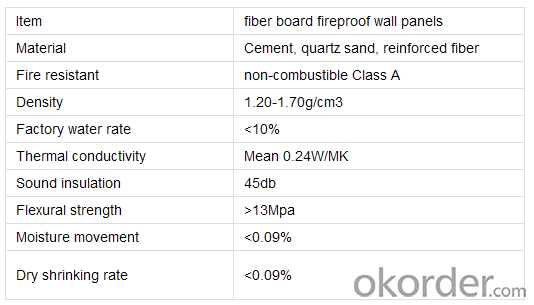

Our fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and temperature advanced technologies. It’s a new building material with excellent performances.

Product Advantages:

Standard Size: 1220*2440mm (W*L)

Thickness Range: 5mm~30mm

Packing: Pcs/Pallet

Main Product Features:

Density: 1.2~1.5g/cm3 (medium), 1.5~2.0 (high)

Water Absorption: ≤30% (medium density), ≤25% (high density)

Non-combustibility: Non-Inflammability Class A

Wet Expansion: ≤0.25%

Bending Strength (Dry/Wet): 20/12 MPA (medium density), 24/14 MPA (high density)

Fire Proof & Insulation;

Waterproof and Moisture Proof;

Thermal & Sound Insulation;

High Strength & Light Weight;

Economical;

Good Looking & Easy Installation / Replacement;

Safe & Harmless;

Product Specifications:

Images:

- Q: We're tiling our basement. The floor is plain concrete. Do I need to put a layer of plywood, then a layer of cement board, then the tiles, or do I just need a layer of cement board then the tiles?

- Glue your cement board down with cement construction adhesive and let cure for 24 hours. You are now ready to start laying tile Hope this helps you and good luck. Richard

- Q: I'm concerned about the silica dust. Should I hire someone?

- You have a minor concern. Wear a respirator if possible. At least a dust mask. If the board was properly put down you also have to scrape up thin set under the board.Thin set also contains silica Plastic off all doors, cabinets vents ( hot and cold) and cover furniture. You ll do a better job at doing this than any one you hire. Or you cover it and hire some one. It s hard, very dusty job. Usually a one time deal isn t a concern ( as long as you take precautions) unless you have breathing problems. I ve dealt with doing this sort of work for 20+ years and no problem. Any questions you can e mail me through my avatar. GL

- Q: Older house, kitchen floor. There's 3/4 diagonal wood on floor joists after hardwood floor is removed. Can I put down 1/2 plywood/ osb and expect the ceramic tile and grout to last? 100% better to use cement board or that synthetic strand board?

- am i the only one who heard him say he wants a long lasting floor? ten years ago only the worst of hacks would use cement board on floors, i'm not even gonna talk about tiling on plywood. now everyone uses it on floors and they last about five years. what happened to mudding floors? lasts forever! much cheaper too. thought it was the rule! too many weekend warriors in the trades these days thanks to the home depot. what's next, perhaps a medical depot? mabye they'll start selling do it yourself surgery or cast in a can . sounds crazy but if it happened tomorrow you guys will be answering medical questions just as recklessly. stop reading labels as answers. don't any of you wanna see proof anymore? get real people. long lasting floors require tar paper, lathe, portland and sharp sand as a base. not cement board and certianly not glued sawdust or woodchips!

- Q: An exhibition, you can use the cement board to do arc shape of the wall? If so, what about the specific building steps?

- With wood Fang and wood to do just to facilitate, or with steel, first made of curved structure, and then board

- Q: I've put up my cement board walls now not sure what 2 use on it as a thin coat? I am not going 2 put tile on just want a textured cement look. Also is there a metalic type paint I can use on cement? I'm looking for options in my new shower area. There is a wax or plastic also that looks like it was a type of tile adhesive that I don't know how to get off before I stain or paint the concrete. Any suggestions on how to get it off? Can I use spray paint on the concrete in a shower area? Thank you

- Cement backer board is okay but probably a bit of over kill for most applications since the backsplash really doesn't get wet in most kitchens. In our last house the tile was applied to common drywall and worked just fine for the 25 years we lived in the house. Our current house has green drywall board which is more moisture resistant than common drywall but is not waterproof like cement board.

- Q: I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- Yes, unfortunately you will. If you tile directly onto the sub floor, the tile is likely to develop cracks. The sub-floor is probably 3/4 material, so an additional 1/2 thick cement board should work.

- Q: Home improvement wall is made of light steel keel + gypsum board, light steel keel + cement pressure plate is good or red brick light weight brick good?

- You can use the first program, light steel keel + sound-absorbing cotton, gypsum board, even if you want to hang TV no problem, which add skeleton on the line, so you can avoid the brick wall caused by the load-bearing problem.

- Q: do i need mortar under the cement board?

- no you just screw it to the wall or studs. then after its up you tape and mortar the joints with special mortar and tape. then you tile or put you tub surround up over it

- Q: Can I just paint a stone on a cemented fiberboard?

- Yes, as long as the cement surface to ensure the smoothness of the surface roughness and verticality can be directly sprayed. Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, after the pulp, copy, pressure, conservation made of a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board.

- Q: Is it okay to install ceramic tile on greenboard, or is cement board necessary?

- Bigg_dogg44 is correct on the question above. Also in addition if you are going to set tiles use versa bond flex white as it has a better bond. do not use mastic for wet areas

Send your message to us

Fiber Cement Board for Interior a nd Exterior Walls

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords