Customized Colorful Aluminum Profiles - Aluminium Foil Stocks Warehouse Warehouse Price

- Loading Port:

- Shanghai

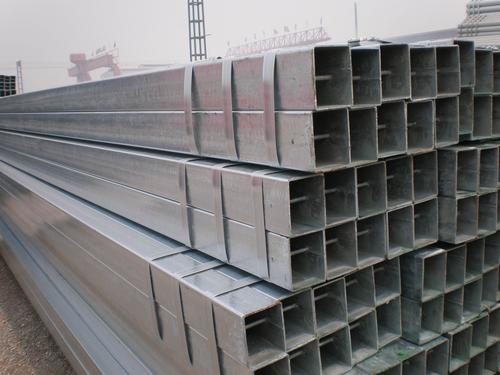

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and also the other grades are all best-selling in China now,

is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, mirror finish aluminium cold roled and hot rolled

sheet, aluminum casting coil, etc.

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Jiangyin aluminum manufacturer, including aluminum, aluminum, cell Longding Xieji Xinyu aluminum, aluminum, aluminum, aluminum Donghua Jianbang started earlier, larger scale. Their market is mainly in East china.

- Q: Industrial aluminum profiles are generally used in what industry?

- Kunshan Austrian crown aluminum to tell you: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.

- Q: Are aluminum profiles suitable for food processing applications?

- Yes, aluminum profiles are suitable for food processing applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for use in industries such as food processing where hygiene and cleanliness are crucial. Additionally, aluminum profiles can be easily cleaned and maintained, ensuring the safety and quality of the food being processed.

- Q: What are the different surface patterns available for aluminum profiles?

- Some of the different surface patterns available for aluminum profiles include brushed, anodized, powder coated, polished, and textured finishes.

- Q: What is the composition of aluminum profiles?

- Aluminum profiles are typically composed of aluminum alloy, which is a combination of aluminum and other elements. The specific composition of aluminum profiles can vary depending on the intended use and desired characteristics. Common alloying elements include copper, magnesium, silicon, and zinc. These elements are added to enhance the strength, durability, and corrosion resistance of the aluminum profiles. Additionally, trace amounts of other elements may be present to further refine the properties of the profiles. Overall, the composition of aluminum profiles is carefully engineered to ensure optimal performance and versatility in various applications.

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles are known for their exceptional durability and resilience, making them highly capable of handling extreme weather conditions. Due to their inherent corrosion resistance, aluminum profiles can withstand harsh weather elements such as heavy rain, snow, extreme temperature fluctuations, and even high levels of UV radiation without corroding or deteriorating. One of the key attributes of aluminum is its ability to create a protective oxide layer on its surface, known as aluminum oxide. This layer acts as a natural barrier, shielding the metal from moisture, salt, and other corrosive agents present in the atmosphere. As a result, aluminum profiles remain unaffected by rain or snow, and they do not rust or corrode like other metals. Furthermore, aluminum's thermal conductivity allows it to quickly dissipate heat, preventing any damage caused by extreme temperature variations. Whether exposed to scorching heat or freezing cold, aluminum profiles expand and contract minimally, which helps maintain their structural integrity and prevents warping or cracking. Moreover, aluminum profiles can withstand high wind loads, making them suitable for areas prone to hurricanes, tornadoes, or strong gusts. Their lightweight yet sturdy nature enables them to withstand significant pressure without bending or breaking. In terms of UV radiation, aluminum profiles have excellent resistance to fading and discoloration. They can effectively endure prolonged exposure to sunlight without losing their original color or surface finish. This makes them an ideal choice for outdoor applications, such as windows, doors, and facades, where they remain visually appealing and structurally sound even in extreme weather conditions. Overall, aluminum profiles exhibit remarkable durability, corrosion resistance, thermal stability, and resistance to UV radiation, allowing them to effectively handle and withstand the challenges posed by extreme weather conditions.

- Q: Can aluminum profiles be used in agricultural machinery manufacturing?

- Yes, aluminum profiles can be used in agricultural machinery manufacturing. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it suitable for various components such as frames, brackets, and structural parts in agricultural machinery. Its versatility also allows for customization and easy integration with other materials, contributing to the overall efficiency and performance of the machinery.

- Q: This question asks for a list of various fastening methods or components used to attach aluminum profiles in roofing systems.

- <p>In roofing systems, various types of fasteners are used to secure aluminum profiles, ensuring stability and longevity. Some common fasteners include: 1. Self-tapping screws, which thread directly into the aluminum without pre-drilling. 2. Rivets, which join two pieces of aluminum by compressing them together. 3. Nuts and bolts, used in conjunction with pre-drilled holes for a secure fit. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, used for bonding profiles in situations where mechanical fasteners are not suitable. 6. Clips and brackets, which can be used to attach profiles to other structural elements. Each type of fastener has its specific application and is chosen based on the design requirements and environmental conditions of the roofing system.</p>

- Q: Are aluminum profiles suitable for roofing systems?

- Yes, aluminum profiles are suitable for roofing systems. Aluminum is a lightweight and durable material that offers numerous advantages for roofing applications. It is highly resistant to corrosion, making it suitable for various weather conditions and ensuring long-term performance. Aluminum profiles also have excellent thermal properties, reflecting heat and reducing energy consumption for cooling purposes. Additionally, aluminum is easy to work with, allowing for flexibility in design and installation. Overall, aluminum profiles are a popular choice for roofing systems due to their strength, longevity, and aesthetic appeal.

Send your message to us

Customized Colorful Aluminum Profiles - Aluminium Foil Stocks Warehouse Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords