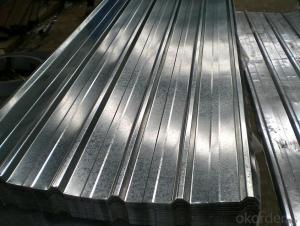

Corrugated Aluminum Panel in Different Corrugation Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Corrugated Aluminum Panel in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

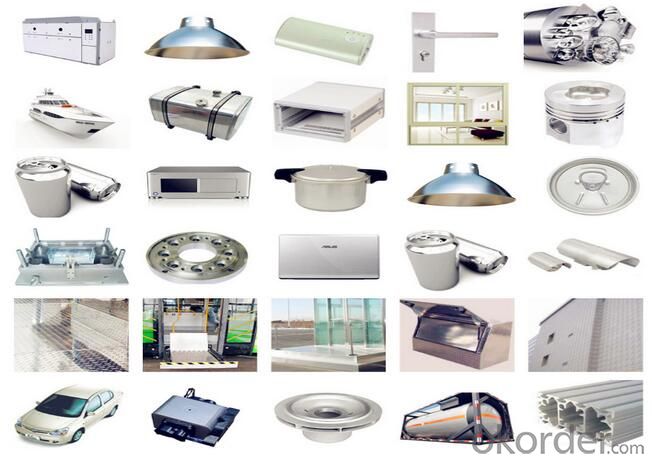

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in various applications.

- <p>Advantages of using aluminum sheets include their lightweight nature, which reduces transportation and handling costs. They are also corrosion-resistant, making them suitable for outdoor applications. Aluminum sheets are recyclable and environmentally friendly, with a high recycled content rate. They are also easy to fabricate and can be cut, bent, and shaped into various forms. Disadvantages include lower strength compared to steel, which may require thicker sheets for certain applications. They can also be more expensive than some other materials, and their light reflection can sometimes be a concern in certain environments.</p>

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically classified as Class A, indicating a high level of fire resistance.

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: Are aluminum sheets suitable for hydraulic applications?

- Yes, aluminum sheets are suitable for hydraulic applications. Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity, making it a suitable material for hydraulic systems. It is commonly used in the construction of hydraulic tanks, cylinders, and other components due to its durability and ability to withstand high pressure and fluid flow.

- Q: What are the typical thicknesses of aluminum sheets?

- The typical thicknesses of aluminum sheets vary depending on their intended use, but they usually range from 0.006 to 0.25 inches.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Cutting, drilling, and shaping aluminum sheets is generally quite easy, especially when working with 101 aluminum. This alloy is known for its malleability and lightweight nature, making it more manageable compared to other metals. It offers good formability and weldability, making it suitable for various fabrication processes. To cut aluminum sheets, common tools such as saws, shears, or even a simple utility knife can be used. Similarly, drilling holes in aluminum sheets is relatively effortless and can be done using standard drill bits. Shaping aluminum sheets can be accomplished through bending, folding, or by utilizing specialized tools like a brake press. However, it is crucial to always prioritize safety and use appropriate measures and equipment when working with any metal, including aluminum.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: How do I clean and maintain aluminum sheets?

- In order to clean and maintain aluminum sheets, there are several steps that can be followed: 1. To begin, one should prepare a cleaning solution by combining warm water with a mild detergent or dish soap in a bucket or sink. It is important to avoid using harsh chemicals or abrasive cleaners as they can cause damage to the aluminum. 2. Next, immerse a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. It is necessary to ensure that the entire surface is covered, with special attention given to any stains or dirt build-up. 3. In the case of stubborn stains or grime, a non-abrasive brush or toothbrush can be used to scrub the affected areas. However, caution should be exercised to prevent applying excessive pressure, as this may result in scratching the aluminum. 4. Following the cleaning process, the sheets should be thoroughly rinsed with clean water to eliminate any residue from the cleaning solution. It is important to ensure that all soap is completely rinsed off. 5. Once rinsed, a clean and dry cloth should be used to remove any excess water and dry the aluminum sheets. This step aids in preventing water spots or stains from forming. 6. To preserve the shine and condition of the aluminum, a thin layer of aluminum polish or wax can be applied. It is advisable to follow the manufacturer's instructions for the best outcomes. 7. Regular inspection of the aluminum sheets is recommended to detect any signs of damage, such as dents, scratches, or corrosion. If any issues are noticed, they should be promptly addressed to prevent further harm. It is crucial to handle aluminum sheets with care to avoid damage. The use of abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface should be avoided. Regular cleaning and maintenance will assist in preserving the appearance and prolonging the lifespan of the aluminum sheets.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- it will make your penis larger because of the fact it is going to construction up scar tissue. In time you may have a extensive thick cuck and the ladies persons will like it. additionally, you will get such thick skin on it which you are going to have little or no sensation, which ability you may carry on very very nearly without end. the ladies will initiate speaking approximately you and different ladies will want to be sure for themselves. So those physique builders can loaf around with sweaty mens with their toddler oil and their spandex. you would be scoring with a distinctive chick everynight.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets can vary depending on the thickness of the sheet and the specific alloy being used. However, in general, a typical bend radius for aluminum sheets ranges from 0.8 to 2 times the thickness of the sheet.

Send your message to us

Corrugated Aluminum Panel in Different Corrugation Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords