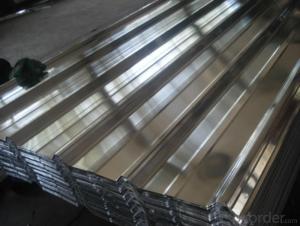

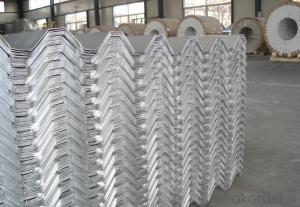

Aluminum Composite Sheets Los Angeles - Extruded Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Extruded Aluminum Plate in Different Corrugation Profiles

Specifications

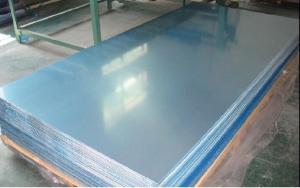

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

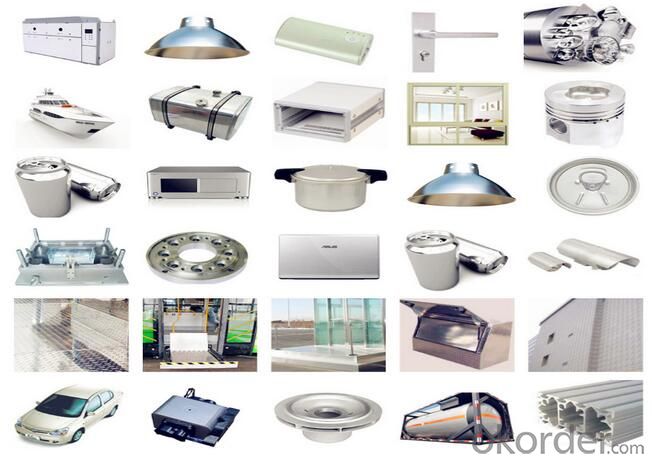

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

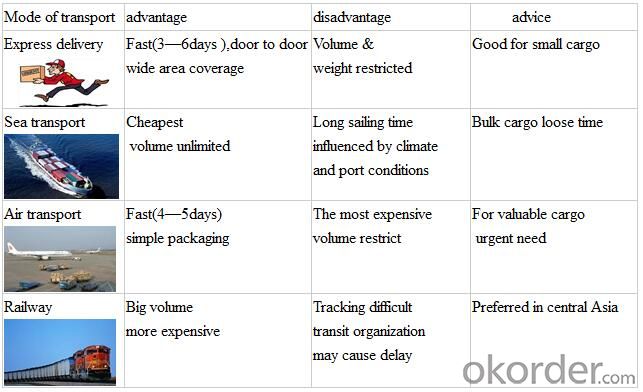

Shipment

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can aluminum sheets be used in electrical applications?

- Aluminum sheets have the capability to be employed in electrical applications. Due to its adeptness in conducting electricity, aluminum is frequently utilized in diverse electrical components and applications. In power transmission lines, bus bars, and electrical enclosures, aluminum sheets are frequently employed as conductive materials. Moreover, their exceptional thermal conductivity properties make them valuable in the production of capacitors, transformers, and heat sinks. Furthermore, aluminum sheets are lightweight and resistant to corrosion, rendering them appropriate for electrical applications where weight and durability are crucial considerations.

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- So convert 27,8 g iron to moles, and convert that to a mass of aluminium 2. 3 CuNO3 + Fe3+ -- Fe(NO3)3 + 3 Cu+ 3. 2 Fe3+ + 3 O2- --- Fe2O3 So convert Fe2O3 from 20,8 grams to moles. Multiply this answer by two. Convert to a mass of Fe3+ 4. H2SO4 + 2 KOH -- K2SO4 + 2 H2O again, 150 grams of H2SO4 to moles, then convert that amount to an amount of mass of K2SO4 5. Na2CO3 + 2 H3O+ + Cl- --- CO2 + 3 H2O + NaCl

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

- Q: Are 101 aluminum sheets suitable for interior design or architectural applications?

- Yes, 101 aluminum sheets are suitable for interior design or architectural applications. 101 aluminum is a common alloy that offers good strength, corrosion resistance, and excellent formability. It can be easily cut, shaped, and fabricated to create various architectural elements such as wall panels, ceilings, furniture, and decorative accents. Additionally, 101 aluminum sheets can be finished with different coatings or textures to enhance their visual appeal and durability. Overall, 101 aluminum sheets are a versatile and cost-effective choice for interior design and architectural applications.

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets can vary depending on various factors such as manufacturing process, heat treatment, and specific alloy composition. However, generally speaking, 101 aluminum sheets have a tensile strength of approximately 27,000 to 42,000 pounds per square inch (psi). It is important to note that this range is an approximation and actual tensile strength values may differ slightly. It is recommended to refer to the specific manufacturer's data sheet or conduct further testing to determine the precise tensile strength of 101 aluminum sheets.

- Q: How do you ensure the flatness of large aluminum sheets?

- To guarantee the flatness of large aluminum sheets, there are several essential measures that can be taken: 1. Choosing the right material: Begin by selecting top-quality aluminum sheets that are specifically designed for flatness. These sheets should have a consistent thickness and minimal internal stress to minimize the risk of warping. 2. Proper storage: Store the aluminum sheets in a controlled environment to prevent exposure to extreme temperature changes or humidity. This will help prevent any potential expansion or contraction of the metal, which can result in warping. 3. Handling and transportation: When moving or transporting the aluminum sheets, ensure that they are evenly supported to avoid any bending or flexing. Use appropriate lifting and handling equipment to avoid putting excessive strain on the sheets. 4. Machining and processing: During the machining and processing stages, it is crucial to employ proper techniques and equipment to maintain flatness. Utilize precision machinery that can handle large sheets and has features to minimize distortion or bending during cutting, drilling, or forming processes. 5. Heat treatment: If necessary, heat treatment can be used to relieve any residual stress in the aluminum sheets. Thermal stress relief techniques, like annealing, can help reduce internal stress and enhance flatness. 6. Quality control: Implement a rigorous quality control procedure to ensure the flatness of the aluminum sheets. This can involve regular inspections using precision measuring instruments, such as straightedges or laser scanners, to identify any deviations from flatness. If any issues are detected, corrective actions can be taken promptly. By following these steps, manufacturers can guarantee the flatness of large aluminum sheets, a critical requirement for industries such as aerospace, automotive, construction, and manufacturing.

- Q: Is aluminum sheet corrosion-resistant?

- Yes, aluminum sheet is corrosion-resistant due to its natural oxide layer that forms on its surface, protecting it from corrosion and making it suitable for various applications in industries such as construction, automotive, and aerospace.

- Q: Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum is an excellent conductor of electricity, and its high conductivity allows for efficient transmission of electrical current. Aluminum sheets are commonly used in electrical applications such as power transmission lines, electrical wiring, and electrical enclosures. Additionally, aluminum is lightweight, which makes it easier to handle and install. It is also resistant to corrosion, which ensures long-term durability and reliability in electrical systems. However, it is important to note that aluminum has a lower conductivity compared to copper, so it may require larger gauge sizes to compensate for this difference. Overall, aluminum sheets are a viable and cost-effective option for various electrical applications.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal material for lightweight applications. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where weight reduction is crucial. They offer excellent corrosion resistance, durability, and formability, allowing for easy fabrication and installation. Additionally, aluminum sheets can be easily joined using various welding and adhesive techniques, further enhancing their suitability for lightweight structures.

Send your message to us

Aluminum Composite Sheets Los Angeles - Extruded Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords