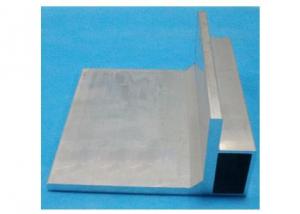

Aluminum Profiles Uk with Different Surface

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Color | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. Aluminum is a lightweight yet strong material that offers numerous advantages for modular construction projects. Firstly, aluminum profiles have excellent structural integrity, making them suitable for supporting various loads in modular buildings. They can withstand heavy loads and provide stability, ensuring the integrity and safety of the entire structure. Secondly, aluminum profiles are corrosion-resistant, which is crucial for modular construction projects that may be exposed to different weather conditions. This resistance to corrosion enhances the durability and longevity of the modular constructions, reducing maintenance costs in the long run. Furthermore, aluminum is highly versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and adaptability in modular construction. This flexibility enables architects and engineers to create innovative and functional modular structures according to specific project requirements. In addition, aluminum profiles are lightweight compared to traditional building materials like steel, making them easier to transport and handle during the construction process. This lightness also contributes to reducing the overall weight of the modular constructions, which can be beneficial in terms of transportation costs and foundation requirements. Moreover, aluminum is a sustainable material as it is 100% recyclable, and its production process requires less energy compared to other materials. This makes it an environmentally friendly choice for modular construction projects, aligning with the growing demand for sustainable building practices. Overall, aluminum profiles offer a range of advantages that make them highly suitable for modular construction. Their strength, corrosion resistance, versatility, lightweight nature, and sustainability make them an ideal choice for creating durable, customizable, and efficient modular structures.

- Q: Household aluminum profiles, which brand of cost-effective? Recommend!

- China's well-known aluminum alloy profiles manufacturing enterprisesChina top ten aluminum profile list / famous brand aluminum alloy profiles1 China Aluminum Group (central management of large state-owned enterprises)The 2 Asia Aluminum Group (Asia's largest aluminum producer, Chinese brand)3 Southwest Aluminum Group ()4 Nanshan aluminum (China famous brand, China well-known trademark, national inspection free products)5 South South aluminum (China well-known trademark)6 BTL Baotou aluminum (China famous brand)7 Zhong Wang aluminum profile (China famous brand, China well-known trademark, national inspection free products)8 (China Jianmei aluminium profile brand, national Mianjian products)9 South Asia Aluminum Profile (China famous brand, national inspection free products)10 Feng aluminum (national Mianjian products)The brands above are all very good...

- Q: Are aluminum profiles recyclable at the end of their useful life?

- <p>Yes, aluminum profiles can be recycled at the end of their lifespan. Aluminum is one of the most recycled materials in the world due to its durability and the energy efficiency of recycling it. The recycling process involves melting the aluminum, which requires significantly less energy than producing aluminum from raw materials. This makes recycling aluminum profiles not only environmentally friendly but also economically viable. The recycled aluminum can be used to produce new aluminum products, contributing to a circular economy.</p>

- Q: Changhe brand aluminum can?

- Profile is not bad, but visibility is not too large, the whole is still very good, cost-effective

- Q: What does T6 mean in aluminum alloy sections?

- The aluminum alloy heat treatment process of the broken bridge aluminum profile: the specific content is as follows:T6 is the deformation of Aluminum Alloy (distinguished from casting Aluminum Alloy) a heat treatment process, is "solid solution treatment (for steel in this process is called" quenching ", everyone should be very familiar with) + artificial aging process", of which the main factor is the solid solution temperature, quenching rate (determined by the quenching medium) and the aging temperature, holding time, time series (an aging or ageing).For different alloys, the same heat treatment code, such as T6, contains values that vary from one factor to another.This process is distinguished from what is commonly known as an annealing process.This process is the key to solving the problems of strength, plasticity, reasonable collocation (high strength and sufficient plasticity) and corrosion resistance.Without deformation of alloy Txxx processing, is absolutely can not be used as a structural material, will be mine, so please rest assured that your car frame (if not from the black hearted miners workshop) must have been processed.2014 aluminum alloy commonly used heat treatment state code has T6, T62, T651 (E), different product shape processing process is slightly different.My MOSSO car shelf is 7005 alloy, the usual process is T53 (V), do not write above also know.Handlebar and handlebar immediately 6061 aluminum alloy T6The above aluminum alloys are all foreign brands

- Q: Can aluminum profiles be used for exhibition booths?

- Yes, aluminum profiles can be commonly used for exhibition booths. Aluminum profiles are lightweight, durable, and easy to assemble, making them an ideal choice for constructing exhibition booths. Additionally, aluminum profiles offer flexibility in design and can be customized to suit specific requirements, making them a popular choice in the exhibition industry.

- Q: Are aluminum profiles suitable for outdoor use and can they withstand weathering?

- <p>Yes, aluminum profiles can be used for outdoor applications. They are resistant to corrosion and weathering due to their inherent properties and can be anodized or powder coated for additional protection against the elements. This makes them suitable for a variety of outdoor uses such as construction, furniture, and signage. However, it's important to ensure that the profiles are properly finished and maintained to prolong their lifespan and performance outdoors.</p>

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles offer a range of fire-resistant qualities that render them suitable for a variety of uses. Firstly, aluminum boasts a remarkably high melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure extreme temperatures without succumbing to melting or compromising its structural integrity. Furthermore, aluminum possesses a low ignition point, necessitating a higher temperature than other metals to ignite. This attribute reduces the likelihood of aluminum catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles generate a protective layer of aluminum oxide on their surface owing to their innate oxide layer. This layer acts as a barrier, impeding the propagation of flames and hindering the combustion process. Moreover, the aluminum oxide layer exhibits exceptional heat resistance, thereby providing supplementary defense against elevated temperatures. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the expansion of a fire. This characteristic assumes critical importance in ensuring fire safety by containing the fire within a specific zone and averting rapid spreading. Taken together, the fire-resistant attributes of aluminum profiles, encompassing their high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, establish them as a dependable choice for a wide range of applications where fire safety is a paramount concern.

- Q: Can aluminum profiles be used in material handling equipment manufacturing?

- Indeed, aluminum profiles have the capability to be utilized in the manufacturing of material handling equipment. These profiles possess properties such as being lightweight, resistant to corrosion, and exhibiting a high strength-to-weight ratio, thus rendering them suitable for the construction of diverse components in material handling equipment. By means of these profiles, frames, support structures, conveyor systems, and other parts of material handling equipment can be effortlessly customized and assembled. Moreover, aluminum profiles provide design flexibility, enabling convenient modifications or additions to the equipment in accordance with specific requirements.

- Q: Can aluminum profiles be used in the automotive industry?

- Indeed, the automotive industry can incorporate aluminum profiles. Lightweight, durable, and corrosion-resistant, these profiles prove ideal for a range of applications in this sector. Commonly employed in the production of car bodies, doors, hoods, and various structural components, aluminum profiles aid in diminishing the overall weight of vehicles. Consequently, this reduction bolsters fuel efficiency and enhances performance. Furthermore, the malleability of aluminum profiles permits effortless extrusion into intricate forms, offering greater design adaptability and innovative solutions in automotive manufacturing.

Send your message to us

Aluminum Profiles Uk with Different Surface

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords