Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

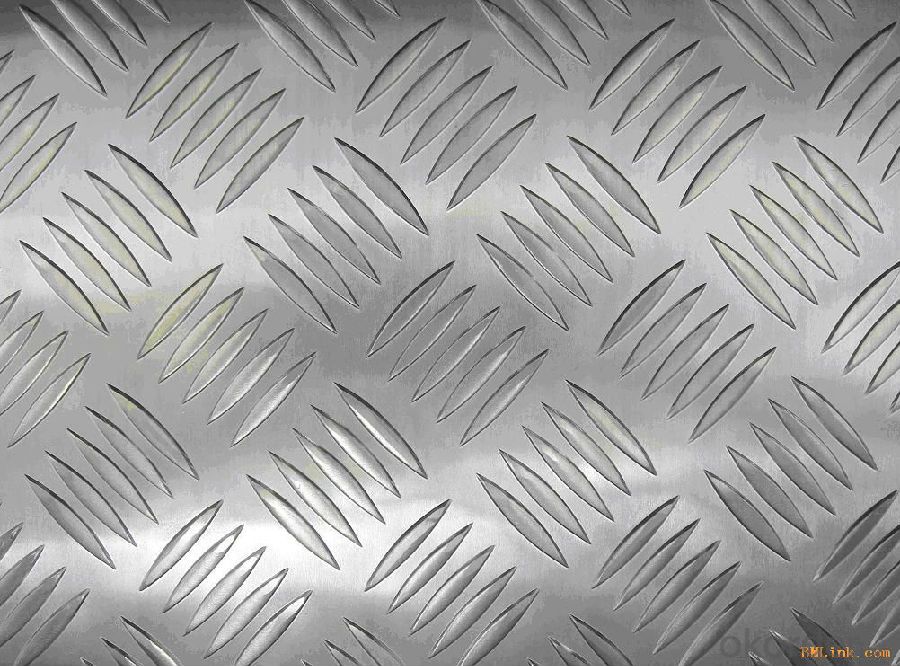

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the weight of the aluminum sheets?

- The weight of the aluminum sheets will depend on their size and thickness.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- I'll do NO2- as an example. The Lewis structure is O=N-O with two electron pairs on the left O and 3 electron pairs on the right O and one electron pair on the N. But you could also draw it as O-N=O. So, those are the two resonance structures. The actual is where N has 1.5 bonds to each O on average.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: Explain how aluminum sheets impact the soundproofing capabilities of a building.

- <p>Aluminum sheets can have a significant impact on the sound insulation of a building. They are often used as a cladding material due to their durability and low maintenance requirements. However, aluminum is a good conductor of sound, which means it can transmit sound waves efficiently. This can reduce the sound insulation of a building, especially if the aluminum sheets are not combined with other soundproofing materials. To improve sound insulation, aluminum sheets can be combined with insulation materials, such as polyurethane foam, to create a barrier that reduces sound transmission. Additionally, using thicker aluminum sheets or adding a layer of sound-absorbing material can help enhance the soundproofing capabilities of a building.</p>

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation. Aluminum is known for its excellent thermal conductivity, which allows it to efficiently transfer heat away from a source. This makes it a popular choice for heat sinks and heat exchangers in various industries. Aluminum sheets can be shaped and formed into different configurations to maximize surface area and enhance heat dissipation. The lightweight and corrosion-resistant nature of aluminum also make it a preferred material for heat dissipation applications.

- Q: This question asks about the impact of aluminum sheets on the air quality inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality. They are inert materials that do not emit volatile organic compounds (VOCs) or other harmful substances. However, the installation process might involve adhesives or sealants that could release VOCs temporarily. Proper ventilation during and after installation can mitigate this issue. Additionally, aluminum sheets can contribute to better air quality by enhancing thermal performance, reducing energy consumption for heating and cooling, and indirectly lowering emissions from power plants.</p>

- Q: I'm making a project for class and I bought a 10 Inch long 5mm thick aluminum/metal, How do you cut it WITHOUT large machinery? is there any power tools adapters or tools that can do this job without a problem?Here is what I have to do:*Cut the metal into ~1x1 and 2X2inch squares*Somehow shave a circle about 2mm deep without going trough the 5mm aluminum (Shaded gray)*Drill a hole right through the 5mm (right in the center)*Drill screw holes on each cornerI provided a really basic pic of what I'm trying to dohttp://img204.imageshack.us/img204/487/77845398.pngRED=backgroundGRAY=drilled 2mm deep WITHOUT GOING THROUGHRED HOLES=screw holes with threadsPlz help need to finish this by friday!PS: Screw holes, and other sizes don't matter right now I'm just trying to figure out what tools/tool adapters I need thanks!

- Steel scissors and Portable hand drill.

- Q: This question asks for an explanation of the various types of coatings applied to aluminum sheets that are used outdoors.

- <p>Aluminum sheets used for exterior applications are often coated to enhance their durability, weather resistance, and aesthetic appeal. The different types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a dry finishing process that provides a uniform and durable finish. 3. PVDF (Polyvinylidene Fluoride) coating, known for its excellent resistance to UV rays and chemicals. 4. Fluorocarbon coatings, which offer superior resistance to weathering and color retention. 5. Electrolytic coating, which involves the application of a thin protective layer through an electrochemical process. Each coating type has specific properties that make it suitable for different exterior applications and environmental conditions.</p>

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: Is aluminum sheet recyclable?

- Yes, aluminum sheet is highly recyclable. Aluminum is one of the most sustainable and environmentally friendly materials, as it can be recycled indefinitely without losing its quality. The recycling process of aluminum sheet involves melting it down to its liquid form, which requires significantly less energy compared to the production of primary aluminum from raw materials. Recycling aluminum sheet not only conserves natural resources but also reduces greenhouse gas emissions and saves energy. It is estimated that recycling one ton of aluminum sheet saves about nine tons of CO2 emissions. Therefore, aluminum sheet recycling is not only economically viable but also an essential practice for maintaining a sustainable and eco-friendly environment.

Send your message to us

Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords