Aluminum Sheets 5032 - Continuous Casting Aluminium Coil AA1050 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

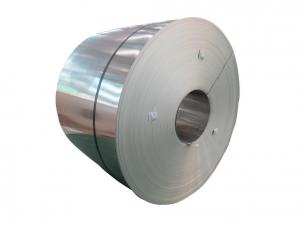

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Stainless steel plate and aluminum plate usually use acrylic structure glue.Acrylic structural adhesive two-component acrylate modified by synthesis and curing agent structural adhesive composition, A, B two agents are 100% solid components; fast curing, high strength, about 5 minutes to 30 minutes after the initial fixation strength up to 80%, 24 hours after the maximum strength; excellent resistance to acid and alkali, water, oil medium, high temperature resistance, better aging properties of metal items between strong adhesion, resistance strength is better than that of epoxy resin, excellent resistance to thermal shock, working at -30~150 DEG C; compliance with international environmental standards, has passed the European ROSH standard.

- Q: Calculate the molar mass of the aluminum oxide. A 5.00g strip of aluminum is reacted in air, producing an oxide weighing 9.36g. Calculate the percent oxygen and aluminum in the compound.Calculate the % error for percent of aluminum calculated.

- 1) Yes, indeed. Al?O? is the correct formula for aluminum oxide. Because the ionic formula is Al?? and O??. (Aluminum has an oxidation number of 3+ ; and oxygen has an oxidation number of 2- . So a neutral ionic compound will have the formula Al?O?. Each element will take the number of the opposite ion.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Disadvantages: * Far more expensive that steel. * Limited to certain geometric features using economical processes. * Abrasive to tooling (aluminum oxide is very abrasive). * Difficult to weld. * Prone to severe spring back. Advantages: Aluminum is the preferred choice for fencing due to several inherent advantages of aluminum. The main advantage is that aluminum components do not rust as easily as iron. Aluminum fences are given a powder-coat finish that protects the surfaces. This kind of a finish also enhances its appearance and provides a smooth surface for painting, if desired. All the components of the fence are drilled and powder-coated prior to assembly. Extreme care is taken during assembly by using sturdy fasteners, brackets, and rivets. Wherever these fasteners, etc., need to be visible, attractive stainless steel ones are used. This provides both looks and strength. As aluminum is an easy metal to work with, a plethora of style choices and adornment options are made available to clients. The flexibility of the metal allows for several designs that can complement the facade of the structure they are installed around.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Yes, aluminum sheets are highly suitable for decorative lighting fixtures. Aluminum is a lightweight and versatile material that is easy to work with and manipulate into various shapes and designs. It offers excellent corrosion resistance, making it suitable for both indoor and outdoor lighting fixtures. Additionally, aluminum can be easily coated or painted to achieve different finishes, allowing for endless design possibilities. Its reflective properties also contribute to enhancing the overall lighting effect, making it an ideal choice for decorative lighting fixtures.

Send your message to us

Aluminum Sheets 5032 - Continuous Casting Aluminium Coil AA1050 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords