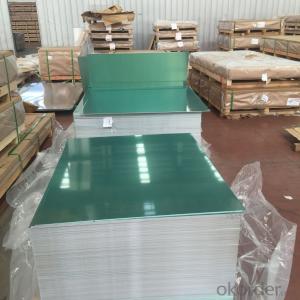

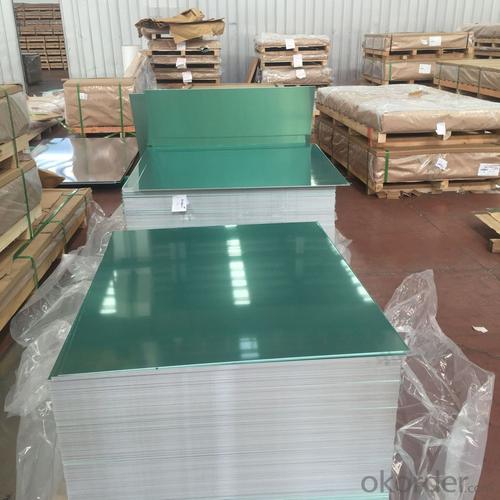

Aluminum Corrugated Metal Sheets - Coated Aluminium Coil AA3003-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Aluminum sheets are tested for quality and compliance with industry standards through a comprehensive set of tests and inspections. These tests ensure that the aluminum sheets meet the required specifications and performance criteria. One of the commonly used tests is the visual inspection, where the sheets are examined for any surface defects such as scratches, dents, or cracks. This is crucial to ensure a smooth and flawless appearance. Further, dimensional checks are performed to verify the thickness, width, and length of the sheets. Precise measurements are necessary to meet the specific requirements of the intended application. To assess the mechanical properties, various tests are conducted. Tensile strength tests evaluate the maximum load the aluminum sheet can withstand before breaking. This helps determine the sheet's structural integrity and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also conducted to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the sheets' mechanical properties and suitability for various applications. Surface integrity is evaluated through corrosion resistance tests, which assess the sheet's ability to withstand environmental factors such as moisture, chemicals, and temperature variations. This is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, aluminum sheets may undergo non-destructive testing techniques such as ultrasonic testing or eddy current testing. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are employed to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are fit for their intended purpose and meet the expectations of customers.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Yes, 101 aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable material, which means it can be easily shaped without breaking or cracking. The specific grade of aluminum, in this case, 101, refers to the alloy composition and may have certain properties that make it more suitable for bending and forming. However, the ability to bend or form aluminum sheets also depends on their thickness, as thicker sheets may require more force and specialized equipment. Overall, with the right tools and techniques, it is possible to bend or form 101 aluminum sheets into a variety of shapes to meet specific requirements.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Use gun bluing . It is the stuff they use on steel guns, it is kind of a dye. Got at a sports store that sells real guns.

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust due to their natural oxide coating that forms a protective barrier against corrosion.

- Q: How is aluminum sheet made?

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- As Vincent noted, aluminium is an abundant element in the earth's crust. It occurs in all clay minerals. Its main ore, bauxite(a mixture of aluminium hydroxides) is still available in vast deposits; particularly in Australia and South America. Aluminium is a reactive element, and so is not found in nature in the elemental form. Aluminium is a metal, and an amphoteric substance; that is; it reacts with both acids and bases.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Fiberglass boats ARE NOT more durable. A typical fiberglass bass boat will last approx 12-15 years with regular use- depending on brand and if you plan to fish tournaments. (Tournaments can ruin a boat in NO time.) Typically, GOOD aluminum hulls will last a LONG time- if properly cared for.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum, get a couple heavy duty buffers and some for your friends and then buy stock in Flitz. You can also get it where you want it and paint it with clearcote to keep it a littl better, or what most do; paint it a light gray or silver color. You can strip it, but strip and paint is not cheap. Also, since the controls are fabric covered, they will never match the polished fuselage, that's why paint is better.

- Q: What is aluminum sheet?

- Aluminum sheet, an often employed material in different industries and applications, refers to a flat and thin piece of aluminum. Its production involves the rolling of aluminum ingots between large rollers until the desired thickness is achieved. Lightweight and durable, aluminum sheets possess exceptional resistance to corrosion, rendering them suitable for a wide array of purposes. In the construction sector, they find common use in roofing, siding, and insulation. Furthermore, their application extends to industries such as automotive, aerospace, packaging, and electrical due to their high conductivity and ease of molding into various shapes. In conclusion, aluminum sheets are highly coveted for their strength, flexibility, and aesthetic appeal, making them an incredibly versatile material.

Send your message to us

Aluminum Corrugated Metal Sheets - Coated Aluminium Coil AA3003-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords