Aluminum Sheets Oregon - Continuous Casting Aluminium Coil AA5052 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

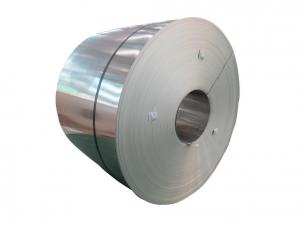

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA5052 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA5052 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is an effective method for cutting aluminum sheets as it utilizes a high-temperature plasma arc to melt and remove the metal, resulting in clean and precise cuts.

- Q: Are aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is known for its excellent resistance to corrosion, even in harsh outdoor environments. It is lightweight, durable, and can withstand various weather conditions, making it an ideal choice for outdoor applications such as roofing, siding, and decorative elements.

- Q: What are the different methods for joining aluminum sheets?

- Depending on the desired outcome and specific application, there are various methods available for joining aluminum sheets. The following are some commonly used techniques: 1. Welding: Different welding techniques, such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW), can be employed to weld aluminum sheets. TIG welding is often preferred for thin sheets as it produces a strong and precise joint. MIG welding, on the other hand, is suitable for thicker sheets and allows for faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be utilized to join aluminum sheets, providing a reliable and sturdy connection. This method allows for easy disassembly if necessary. Rivets are another commonly used mechanical fastening method, where the sheets are secured using a rivet gun that deforms the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often chosen for its ability to create a clean and seamless appearance, making it ideal for situations where aesthetics matter. Adhesive bonding also helps distribute stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process that involves deforming the aluminum sheets using a punch, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that utilizes a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own set of advantages and disadvantages. The choice of method depends on factors such as the desired strength, appearance, production rate, and specific requirements of the application.

- Q: This question asks for methods to protect aluminum sheets from damage during transportation and storage.

- <p>To prevent damage to aluminum sheets during transportation or storage, follow these guidelines: 1) Use protective packaging such as bubble wrap or padded covers to prevent scratches and dents. 2) Store aluminum sheets in a dry, cool place away from moisture and direct sunlight to avoid corrosion. 3) Stack sheets with soft padding between them to prevent surface damage. 4) Securely strap or brace the sheets during transport to prevent movement and potential damage. 5) Handle aluminum sheets with clean, dry hands or use gloves to avoid leaving fingerprints or oils that can cause corrosion. 6) Ensure that transportation vehicles are clean and dry to prevent any contaminants from coming into contact with the aluminum. By adhering to these practices, you can minimize the risk of damage to aluminum sheets.</p>

- Q: could magnet attract iron with the seperation of rubber and aluminum sheets?

- no problem.

- Q: how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a lightweight and durable material that is commonly used in the food industry. It is non-toxic, non-reactive, and does not release any harmful chemicals when it comes into contact with food. Aluminum sheets are also easy to clean and maintain, making them a popular choice for food preparation surfaces in both commercial kitchens and home kitchens. Additionally, aluminum has excellent heat conductivity, allowing for even cooking and baking. However, it is important to note that aluminum can react with acidic or salty foods, causing a metallic taste. To prevent this, it is recommended to use a layer of parchment paper or silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: How is the thickness of aluminum sheets measured?

- A micrometer is typically utilized to measure the thickness of aluminum sheets. This precision instrument consists of a calibrated screw mechanism featuring a spindle and anvil. To determine the thickness of an aluminum sheet, it is positioned between the spindle and anvil of the micrometer. By turning the screw, pressure is applied to firmly secure the sheet in place. The measurement can then be obtained by reading the scale or digital display on the micrometer. Alternatively, a thickness gauge is commonly employed for this purpose. This gauge employs a set of parallel anvils to measure the sheet's thickness. The sheet is inserted into the gap between the anvils, and the measurement can be obtained by reading the scale or display on the gauge. Both methods yield precise and dependable measurements of aluminum sheet thickness.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Yes, aluminum sheets are suitable for manufacturing audio speaker enclosures. Aluminum is a lightweight and durable material that is often used in speaker enclosure construction. It offers good acoustic properties, reduces vibrations, and provides excellent heat dissipation, making it an ideal choice for speaker manufacturing.

Send your message to us

Aluminum Sheets Oregon - Continuous Casting Aluminium Coil AA5052 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords