Aluminum Coil - Continuous Casting Aluminium Coil AA1050 0.2mm-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

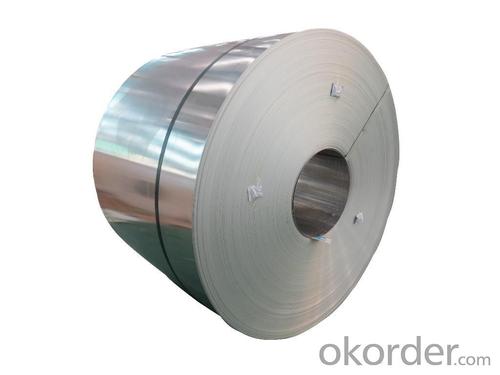

1.Structure of Product Description

Continuous Casting Aluminium Coil is widly used in building materals in the world. This strip can be rolled down to aluminium coil,sheet,circle ect. Compare to other alloy, the alloy AA1050 is much more cheaper. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Products Specifcation

| Alloy | Temper | Thickness | Coil ID | Coil Weight |

| AA1050 | H14 | 0.2mm-3mm | 505mm | 2-2.5 tons |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various industrial applications, including piping systems.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a common material choice for evaporator coils in refrigeration systems due to its excellent heat transfer properties, corrosion resistance, and lightweight nature.

- Q: What are the rules and regulations regarding the use of aluminum coil in commercial kitchen settings?

- <p>Yes, there are regulations on the use of aluminum coil in commercial kitchens. These regulations often relate to food safety, hygiene, and the material's suitability for contact with food. Aluminum is generally safe for food contact, but it must meet specific standards to ensure it does not leach harmful substances into food. Regulations may vary by country or region, with some areas having strict guidelines on the types of aluminum alloys allowed and their intended use. Compliance with these regulations is crucial to avoid health risks and legal penalties. It's important for commercial kitchens to use food-grade aluminum and to follow local health department guidelines.</p>

- Q: How do aluminum coils compare to magnesium coils in terms of strength?

- Aluminum coils are generally stronger than magnesium coils in terms of strength.

- Q: What are the potential applications of coil-coated aluminum coils?

- Coil-coated aluminum coils have a wide range of potential applications due to their versatility and durability. Some common applications include roofing and cladding for buildings, automotive parts, signage, electronics, and appliances. The coil coating process enhances the aluminum's resistance to corrosion, weathering, and fading, making it suitable for both indoor and outdoor uses. Additionally, the ability to apply various colors and finishes to the coils allows for customization and aesthetic appeal in different industries.

- Q: What are the weight and length specifications of aluminum coils?

- The weight and length specifications of aluminum coils can vary depending on the specific application and industry requirements. However, typically aluminum coils can range in weight from a few hundred pounds to several thousand pounds, and in length from a few feet to hundreds of feet.

- Q: How is the welding performance of 3003 aluminum coil?

- 3003 aluminum coil, a kind of rust-proof aluminum, belongs to AL-Mn series alloy. With low intensity (slightly higher than commercial purity aluminum), it cannot endure heat treatment, so cold processing is adopted to increase its mechanical property: high plasticity in annealing and semi-cold hardening, low plasticity in cold hardening, good corrosion resistance., good weldability and bad machinability. It is mainly used for low load part in liquid or gaseous medium requiring high plasticity and good weldability, such as fuel tanks, gasoline or lubricant conduit. It can also be used for liquid containers and other deep drawing small load parts made by deep drawing. Aluminum wire can be used to make the rivet.3003 aluminum sheet has good formability, weldability and corrosion resistance. It is used to process parts which require good formability, corrosion resistance and weldability and lower intensity than 1xxx series alloy, such as such as kitchenware, food and chemical products processing and storage equipment, groove and tank to transport liquid product, pressure vessel and pipe processed from thin plate, cooling fin, make-up board, photocopier rollers and ship material.

- Q: Are aluminum coils suitable for food processing and packaging?

- Yes, aluminum coils are suitable for food processing and packaging. Aluminum is a safe and hygienic material that is resistant to corrosion, odors, and moisture. It is commonly used for packaging food products due to its ability to maintain the freshness and quality of the food, preventing contamination and providing a longer shelf life. Additionally, aluminum coils are lightweight, flexible, and can be easily formed into various shapes and sizes, making them ideal for food packaging applications.

- Q: What are the common maintenance practices for aluminum coils?

- To maintain aluminum coils in good condition, it is necessary to regularly clean them, inspect for any damage or corrosion, and ensure proper airflow around them. Cleaning is crucial to eliminate accumulated dirt, debris, and other contaminants. This can be achieved by gently brushing or vacuuming the coils, or by using a mild detergent and water solution for more stubborn dirt. It's important to avoid the use of harsh chemicals or abrasive materials that could harm the aluminum surface. Inspecting the coils for damage or corrosion is also essential for their performance and longevity. Any signs of physical damage, like dents or bends, should be promptly addressed to prevent further deterioration. Additionally, corrosion can occur due to exposure to moisture or chemicals, so it's important to check for rust or discoloration. If corrosion is present, it should be treated and the cause of it should be identified and resolved to prevent future damage. Proper airflow around the coils is crucial for efficient operation. Obstructions or blockages in the surrounding area should be cleared to ensure adequate air circulation. This may include removing debris or objects that restrict airflow and ensuring appropriate spacing between the coils and nearby objects. Regular inspection of air filters and the ventilation system is also important to prevent any restrictions that could hinder airflow. In conclusion, regular cleaning, inspection, and maintenance of aluminum coils are necessary to ensure optimal performance and prolong their lifespan. It is advisable to follow manufacturer guidelines and seek professional advice if any issues or concerns arise.

- Q: what is the hardness number of aluminium.....? what is the hardness number of aluminium-Sic composite material...?

- I don't believe that Aluminum (US spelling)/ Aluminium (UK spelling) has a Mohs Hardness rating. The Hardness of a material, as measured by the Mohs Hardness scale, is a criterion of its resistance to crushing. [Perry's Chemical Engineering Handbook]. Since aluminum is a metal, and would deform under a crushing-type stress, rather than shatter, it would not have a Mohs Hardness rating. Perhaps you meant **aluminA**, rather than aluminum. Alumina (Al2O3) has a Modified Mohs Hardness of 12. Silicon Carbide (carborundum) has a Modified Mohs Hardness of 13. There's no value listed for the combination, but it should be pretty hard stuff -- likely in the 12-13 range, but potentially even harder. Hope that helps.

Send your message to us

Aluminum Coil - Continuous Casting Aluminium Coil AA1050 0.2mm-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords