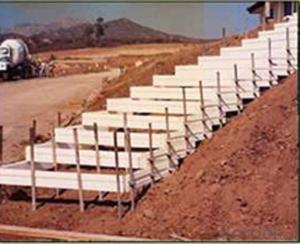

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Circular Column Formwork Outrigger For Scaffolding With New Design

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels..

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

FAQ

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: Can steel frame formwork be used for both interior and exterior concrete elements?

- Yes, steel frame formwork can be used for both interior and exterior concrete elements. Steel frame formwork is versatile and durable, making it suitable for various types of concrete structures. Whether it is a wall, column, beam, slab, or any other concrete element, steel frame formwork can be easily adapted to meet the requirements of the project. Its strength and stability allow for the creation of smooth and precise concrete finishes, making it ideal for both interior and exterior applications. Additionally, steel frame formwork is reusable, which makes it a cost-effective choice for construction projects.

- Q: Channel frame and reinforced concrete structure which is more shockproof

- The seismic performance of steel frame building is better than that of concrete frame structure.

- Q: Can steel frame formwork be used for curved or irregular shapes?

- Yes, steel frame formwork can be used for curved or irregular shapes. Steel frames can be easily adjusted to form various shapes by bending or welding the steel components. This flexibility allows for the creation of complex architectural designs or structures with curved or irregular geometries.

- Q: Are there any limitations to the number of formwork reuses for complex structures using steel frame formwork?

- Yes, there are limitations to the number of formwork reuses for complex structures using steel frame formwork. While steel frame formwork is known for its durability and ability to withstand multiple uses, there are several factors that can impact its reusability. Firstly, the complexity of the structure itself plays a significant role in determining the number of formwork reuses. Complex structures often require intricate and customized formwork systems, which may not be as durable or easily reusable as standard formwork systems. The more complex the structure, the higher the likelihood of damage or wear and tear to the formwork, reducing its reusability. Secondly, the quality of the formwork and its maintenance also affect its reusability. Regular inspection, maintenance, and repairs are necessary to ensure the formwork remains in good condition. Failure to maintain the formwork properly can lead to damage or deformation, limiting its ability to be reused. Additionally, the type and quality of concrete used can impact the life span of the formwork. Harsh chemicals or aggressive concrete mixtures can cause corrosion or deterioration of the formwork, reducing its reusability. Lastly, the handling and storage of the formwork also play a role in its reusability. Improper handling, stacking, or storage can cause damage or deformation to the formwork, rendering it unusable for future projects. In conclusion, while steel frame formwork is generally durable and can be reused multiple times, the complexity of the structure, the quality and maintenance of the formwork, the type of concrete used, and the handling and storage practices can all impose limitations on its reusability. It is essential to consider these factors and assess the condition of the formwork before determining its suitability for reuse in complex structures.

- Q: How does steel frame formwork contribute to the overall aesthetics of a concrete structure?

- Steel frame formwork contributes to the overall aesthetics of a concrete structure in several ways. Firstly, steel frame formwork allows for greater precision and accuracy in the placement of concrete, resulting in a smoother and more uniform finish. This is especially important in projects where the exposed concrete surface is intended to be a prominent design feature. Additionally, steel frame formwork provides flexibility in terms of shaping and molding the concrete. The steel frames can be easily adjusted and customized to create different shapes, curves, and patterns, allowing for more creative design possibilities. This enables architects and designers to create unique and visually appealing concrete structures that stand out from traditional construction techniques. Moreover, steel frame formwork helps in achieving a consistent and level surface finish across the entire structure. The rigid and sturdy nature of steel frames ensures that the formwork remains stable and does not deform during the concrete pouring process. This eliminates the risk of uneven surfaces or imperfections, resulting in a visually pleasing and professional appearance. Furthermore, steel frame formwork also contributes to the durability and longevity of the concrete structure. The use of steel frames provides strong support and reinforcement to the concrete, making it more resistant to external forces and potential damage. This ensures that the structure maintains its aesthetic appeal over time, as the concrete surface remains intact and free from cracks or deterioration. Overall, steel frame formwork plays a vital role in enhancing the overall aesthetics of a concrete structure. It allows for precise and accurate placement of concrete, provides flexibility in design, ensures a consistent and level finish, and contributes to the durability and longevity of the structure. By combining functionality and aesthetics, steel frame formwork helps create visually stunning and architecturally impressive concrete structures.

- Q: How does steel frame formwork contribute to the overall sustainability of a construction project?

- Steel frame formwork contributes to the overall sustainability of a construction project in several ways. Firstly, steel is a highly durable material that can withstand the rigors of construction, ensuring the longevity of the formwork system. This durability reduces the need for frequent replacements, leading to a reduction in waste generation and the consumption of resources. Secondly, steel frame formwork is reusable. Unlike traditional timber formwork, which is often discarded after a single use, steel frame formwork can be dismantled and reused multiple times, significantly reducing the amount of material waste and minimizing the environmental impact of the construction process. Additionally, steel is a recyclable material. At the end of its useful life as formwork, steel frames can be recycled and used in the production of new steel products, further reducing the demand for virgin materials and conserving natural resources. Moreover, steel frame formwork offers flexibility in design and construction. Its modular nature allows for easy customization and adjustment, reducing the need for excessive material cutting and minimizing construction waste. This adaptability also ensures efficient use of resources and reduces the overall environmental footprint of the project. Furthermore, steel frame formwork enables faster construction compared to traditional formwork systems. The speed and efficiency of construction result in reduced energy consumption, lower carbon emissions, and a smaller environmental impact. In conclusion, steel frame formwork contributes to the overall sustainability of a construction project by promoting durability, reusability, recyclability, flexibility, and efficiency. By incorporating steel frame formwork, construction projects can minimize waste generation, conserve resources, reduce carbon emissions, and create more sustainable built environments.

- Q: How does steel frame formwork contribute to the overall aesthetics of a building?

- Steel frame formwork does not directly contribute to the overall aesthetics of a building as it is a temporary structure used during construction. However, it plays a crucial role in achieving accurate and precise concrete construction, which in turn can enhance the overall aesthetics of the building. By providing a strong and rigid framework, steel formwork ensures smooth and seamless finishes, straight lines, and precise dimensions, which are essential for creating visually appealing architectural elements.

- Q: Can steel frame formwork be used for the construction of commercial buildings?

- Yes, steel frame formwork can be used for the construction of commercial buildings. Steel frame formwork provides strong support and stability, making it suitable for handling the weight and load requirements of commercial buildings. Additionally, steel frame formwork can be easily assembled, disassembled, and reused, making it a cost-effective choice for commercial construction projects.

- Q: Does steel frame formwork require any specific waterproofing measures?

- Yes, steel frame formwork does require specific waterproofing measures. Although steel is a durable material, it is not inherently waterproof. Therefore, in order to prevent water leakage and ensure the integrity of the formwork, some waterproofing measures are necessary. One common method used to waterproof steel frame formwork is the application of a waterproofing coating or membrane. This can be applied to the surface of the formwork to create a barrier against water penetration. The type of waterproofing material used will depend on the specific project requirements, but commonly used materials include bitumen, acrylic-based coatings, or polyurethane membranes. Additionally, proper joint sealing is crucial for preventing water ingress. Sealing all joints, connections, and penetrations in the steel frame formwork system with waterproof sealants or tapes will help to create a watertight structure. This includes sealing the joints between individual formwork panels as well as any gaps or openings where water could potentially enter. It is also important to ensure proper drainage and slope design to prevent water accumulation on the formwork surface. The design should include adequate drainage channels or weep holes to allow any water that does penetrate the formwork to drain away efficiently. Furthermore, regular inspections and maintenance are essential to identify and address any potential areas of water leakage or damage. This includes checking the condition of the waterproofing materials, repairing any cracks or damages, and addressing any issues that may compromise the waterproofing system. Overall, while steel frame formwork offers numerous advantages in construction, it does require specific waterproofing measures to protect against water infiltration. Implementing proper waterproofing techniques and regularly maintaining the formwork system ensures its longevity and effectiveness in preventing water damage.

- Q: How does steel frame formwork contribute to the overall thermal insulation of a concrete structure?

- The thermal insulation of a concrete structure is not directly affected by steel frame formwork. The main purpose of steel frame formwork is to provide temporary support and shape to the concrete during the pouring and curing process. Its primary function is to guarantee the concrete's structural integrity and achieve the desired shape and dimensions. However, there are other methods to enhance the overall thermal insulation of a concrete structure. For example, insulation materials like polystyrene boards, foam concrete, or expanded polystyrene (EPS) blocks can be incorporated into the design to improve its thermal performance. These materials are typically placed between the concrete walls or slabs, acting as a barrier against heat transfer and reducing thermal bridging. Moreover, additional elements such as double-glazed windows, high-performance insulation coatings, and proper sealing techniques can be utilized to further boost the thermal insulation of the concrete structure. These measures help minimize heat loss or gain through the building envelope, resulting in improved energy efficiency and reduced heating or cooling demands. Although steel frame formwork does not directly contribute to thermal insulation, it plays a vital role in ensuring the structural integrity of the concrete structure, which indirectly impacts the overall energy efficiency and sustainability of the building.

Send your message to us

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords