Steel Coupler Rebar Scaffolding Outrigger Concrete Slab Formwork Scaffolding System High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Coupler Rebar Scaffolding Outrigger Concrete Slab Formwork Scaffolding

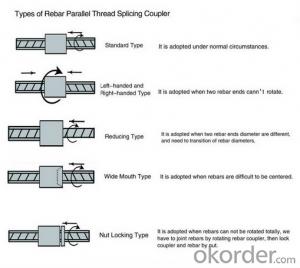

1.Description:

Lapped joints are not always an appropriate means of connecting rebar. The use of Steel Rebar Couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

The threaded steel coupler system is designed as a threaded reinforcement connection with 100% load transmission. The steel coupler rebar connection system is suitable for both static and dynamic load transmission in construction joints.

The coupler is designed as a threaded reinforcement connection for formed construction joints. Reinforcement work is normally carried out on both sides of the construction joint using lap joints or one side is anchored. The bar lengths are based on the structural analysis requirements of the building component and are calculated from anchorage and lap lengths.

2.Advantages of Steel Coupler Rebar Lift Scaffolding Galvanized Scaffolding Tube with Low Price:

The coupler system provides the opportunity to connect rebars quickly, easily and cost effectively, even when large rebar diameters are used. This makes the steel coupler rebar range a logical extension to our rebendable CNBM reinforcement continuity system for rebars over 12 mm.

3.Available sizes of Steel Coupler Rebar Lift Scaffolding Galvanized Scaffolding Tube with Low Price:

14mm,16mm,18mm,20mm,22mmm,25mm,28mm,32mm,36mm,40mm

4.Delivery:

Delivery Term: FOB / CFR / CIF available.

Delivery Time: 15 days or less after order confirmed.

5.Why choose us?

Technical Expertise

Experienced Management

Stringent Quality Control

Exemplary Service

On-Time Delivery

Wide Product Range

Competitive Pricing

Huge branch network capable of catering worldwide

- Q: How does steel formwork prevent concrete segregation during pouring?

- Steel formwork prevents concrete segregation during pouring by providing strong and rigid support to the concrete mixture. It holds the concrete in place, preventing it from separating into its individual components, such as sand, aggregates, and cement. The steel formwork also helps in controlling the flow of concrete, ensuring that it is evenly distributed throughout the structure, reducing the chances of segregation.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Steel formwork is suitable for both monolithic and composite construction. In monolithic construction, concrete is poured continuously to form a solid structure, and steel formwork provides reliable support until the concrete sets and hardens. It is easy to assemble and disassemble, making it efficient for monolithic projects. Composite construction involves combining different materials for a stronger structure. Steel formwork can also be used in composite construction, particularly when concrete is combined with materials like steel beams or columns. The steel formwork acts as a mold, enabling the concrete to be poured and shaped around the other materials to create the desired structure. In summary, steel formwork is a versatile choice for construction projects, including monolithic and composite methods. Its strength, durability, and ease of use make it a popular option for contractors and builders in a wide range of projects.

- Q: How does steel formwork affect the overall labor requirements of a construction project?

- Steel formwork can greatly impact the overall labor requirements of a construction project in several ways. Firstly, steel formwork is highly durable and robust, which means it can be reused multiple times. This reduces the need for labor-intensive tasks such as constantly constructing and dismantling formwork, resulting in significant time and cost savings. Moreover, steel formwork is much quicker to assemble and disassemble compared to traditional timber formwork. This increased efficiency allows construction projects to progress at a faster pace, reducing the overall duration of the project and minimizing labor requirements. Additionally, steel formwork offers greater dimensional accuracy and stability, resulting in fewer adjustments and modifications during the construction process. This reduces the need for labor-intensive rework and ensures that the project stays on schedule. Furthermore, steel formwork can be easily customized and fabricated to meet specific project requirements, which allows for faster and more precise construction. This reduces the need for manual alterations and adjustments, saving both time and labor. Lastly, steel formwork provides a safer working environment for laborers. Its sturdy structure and ability to withstand heavy loads enhance worker safety, reducing the risk of accidents and injuries. This not only ensures the well-being of the workforce but also minimizes potential delays and labor requirements caused by injuries. Overall, steel formwork can significantly reduce the labor requirements of a construction project by streamlining the construction process, enhancing efficiency, improving accuracy, and enhancing worker safety.

- Q: What are the common safety certifications for steel formwork?

- There are several common safety certifications for steel formwork used in construction projects. These certifications ensure that the steel formwork meets specific safety standards and regulations. One of the most well-known certifications is the OSHA (Occupational Safety and Health Administration) certification. This certification ensures that the steel formwork complies with the safety regulations set forth by OSHA. It covers various aspects such as stability, load-bearing capacity, and structural integrity. Another widely recognized certification is the ANSI (American National Standards Institute) certification. ANSI provides standards for construction equipment and materials, including steel formwork. This certification ensures that the formwork meets the necessary safety requirements, including strength, durability, and stability. The European standard EN 12812 is also an important certification for steel formwork used in Europe. It sets out the requirements for formwork systems and verifies their safety and performance. This certification covers aspects such as load-bearing capacity, stability, and safety factors. Additionally, the International Organization for Standardization (ISO) provides certifications related to steel formwork safety. The ISO 9001 certification ensures that the manufacturer has a quality management system in place, while the ISO 45001 certification focuses on occupational health and safety management systems. Other specific certifications may be required depending on the country or region. For example, in the United Kingdom, the British Standards Institution (BSI) certification may be necessary. Overall, these safety certifications for steel formwork provide assurance to construction professionals that the formwork they are using meets the necessary safety standards and regulations. It is essential to ensure that the steel formwork used on construction sites holds these certifications to prevent accidents, ensure worker safety, and maintain the structural integrity of the formwork.

- Q: Is steel formwork suitable for all types of concrete structures?

- Steel formwork is generally considered to be suitable for a wide range of concrete structures. However, its suitability may depend on several factors such as the design requirements, budget, and project timeline. Steel formwork offers several advantages over other types of formwork systems. It is known for its high strength and durability, which allows it to withstand the pressure exerted by the fresh concrete without warping or deforming. This makes it particularly suitable for structures that require large concrete pours or have complex geometries. Moreover, steel formwork provides excellent dimensional accuracy, ensuring that the final concrete structure meets the required specifications. It also allows for easy customization, enabling the formwork to be tailored to the specific needs of the project. However, there are instances where steel formwork may not be the most suitable option. For example, if the budget is limited, steel formwork may be more expensive compared to alternatives such as timber or plastic formwork. Additionally, if the project has a tight schedule, steel formwork may require more time for fabrication and assembly compared to other systems. Furthermore, steel formwork may not be the best choice for structures that have strict aesthetic requirements. The steel panels may leave imprints on the concrete surface, which may not be desirable in certain architectural designs. In conclusion, while steel formwork is generally suitable for a wide range of concrete structures, its suitability may vary based on project-specific factors such as design requirements, budget, and timeline. It is important to carefully evaluate these factors before deciding on the most appropriate formwork system for a particular project.

- Q: Can steel formwork be used for swimming pool construction?

- Yes, steel formwork can be used for swimming pool construction. Steel formwork is a versatile and durable option that is commonly used in the construction industry for various applications, including swimming pool construction. It offers several advantages such as high strength, stability, and reusability, making it suitable for constructing swimming pool walls, floors, and other structures. Steel formwork provides a smooth and precise finish, ensuring that the swimming pool walls and floors have a uniform appearance. It is capable of withstanding the pressure exerted by the water, ensuring the structural integrity of the swimming pool. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient construction and easy maintenance. Moreover, steel formwork is highly adaptable and can be customized to meet specific design requirements. It can be used for constructing different shapes and sizes of swimming pools, including both in-ground and above-ground pools. This flexibility makes steel formwork a preferred choice for swimming pool construction projects. However, it is important to consider certain factors when using steel formwork for swimming pool construction. Proper waterproofing measures need to be taken to prevent water leakage and corrosion of the steel. Additionally, adequate reinforcement and support should be provided to ensure the stability and durability of the swimming pool structure. Overall, steel formwork is a suitable option for swimming pool construction due to its strength, durability, and versatility. When used correctly and in conjunction with appropriate waterproofing and reinforcement measures, it can help create a sturdy and aesthetically pleasing swimming pool.

- Q: What are the considerations when designing steel formwork for underground utilities?

- There are several essential factors to consider when designing steel formwork for underground utilities. These considerations encompass: 1. Structural Integrity: It is necessary to ensure that the formwork can withstand the pressure and forces exerted by the surrounding soil and any potential external loads. The design should offer sufficient strength and stability throughout the construction process. 2. Water and Chemical Resistance: Underground utilities are often exposed to water and various chemicals. Consequently, the formwork must be designed to resist corrosion and deterioration caused by these elements, ensuring its durability. 3. Accessibility for Installation and Maintenance: The formwork design should facilitate easy access during installation and future maintenance activities. This may involve incorporating provisions for openings, removable sections, or access points to allow workers to easily reach the utilities when necessary. 4. Modular Design: Utilizing a modular design can provide flexibility and simplify installation. Modular formwork systems enable quick assembly and disassembly, which proves advantageous when dealing with different underground utility layouts and configurations. 5. Safety: Safety is of utmost importance in any construction project. Therefore, the formwork design should include safety features such as guardrails, handrails, and anti-slip surfaces to minimize the risk of accidents and injuries during construction and maintenance. 6. Cost-effectiveness: The design should strike a balance between performance and cost. It should be optimized to minimize material usage and labor costs while maintaining quality and durability. 7. Compatibility with other construction methods: The design should be compatible with other construction methods and materials used for the underground utilities. This encompasses considerations for joining techniques, such as welding or bolting, and compatibility with other materials, such as concrete or PVC pipes. By taking these factors into account, designers can ensure that the steel formwork for underground utilities is structurally sound, resistant to environmental factors, easily accessible for installation and maintenance, safe for workers, cost-effective, and compatible with other construction methods.

- Q: How is steel formwork cleaned and maintained?

- Steel formwork is commonly used in construction projects due to its durability and reusability. To ensure its longevity and to maintain its quality, regular cleaning and maintenance are crucial. Here are some steps to clean and maintain steel formwork: 1. Remove concrete residue: After each use, any concrete residue should be removed from the steel formwork. This can be done by chipping away the hardened concrete using a hammer or chisel. Care should be taken not to damage the formwork surface during this process. 2. Power washing: Once the larger chunks of concrete are removed, power washing can be done using a high-pressure water jet. This helps to dislodge any remaining concrete particles and dirt from the surface of the formwork. Make sure to use appropriate safety measures, such as wearing protective clothing and goggles, while power washing. 3. Chemical cleaning: In cases where stubborn stains or concrete deposits are difficult to remove through power washing alone, a chemical cleaning solution can be used. There are various commercially available concrete removers that can be applied to the formwork surface. Follow the manufacturer's instructions for proper usage and safety precautions. 4. Rust removal and prevention: Steel formwork is susceptible to rusting, which can weaken its structural integrity. Regularly inspect the formwork for any signs of rust and remove it using wire brushes or sandpaper. After rust removal, apply a rust-inhibiting primer or a protective coating to prevent further rusting. This should be done before storing the formwork to ensure it remains in good condition. 5. Proper storage: When not in use, steel formwork should be stored in a clean and dry environment. Avoid exposure to moisture, extreme temperatures, and corrosive substances, as these can adversely affect the formwork's quality. Proper stacking and organization can also prevent damage and deformation during storage. Regular maintenance and cleaning of steel formwork is essential to ensure its longevity and reusability. By following these steps and taking appropriate precautions during cleaning and storage, steel formwork can be kept in optimal condition for future construction projects.

- Q: How does steel formwork compare to timber formwork in terms of durability?

- Steel formwork is generally considered to be more durable than timber formwork. Steel is a strong and resilient material that is able to withstand heavy loads and high pressures without warping or deteriorating. Unlike timber, steel does not rot, warp, or shrink when exposed to moisture or extreme weather conditions. This makes steel formwork suitable for use in various construction projects, including high-rise buildings, bridges, and tunnels, where durability is essential. Additionally, steel formwork has a longer lifespan than timber formwork. Steel is known for its longevity and ability to maintain its structural integrity over time. It does not require frequent replacement or repairs, resulting in cost savings in the long run. Timber formwork, on the other hand, may need to be replaced more frequently due to wear and tear, moisture damage, or insect infestation. Furthermore, steel formwork offers greater flexibility and adaptability. It can be easily fabricated into different shapes and sizes to meet the specific requirements of each construction project. This adaptability allows for efficient and precise construction, reducing labor and material costs. Overall, while timber formwork can be cost-effective and suitable for certain applications, steel formwork is generally considered to be more durable, long-lasting, and versatile. It provides a reliable and resilient solution for construction projects that require high strength and durability.

- Q: How does steel formwork affect the schedule of a construction project?

- Steel formwork can have a positive impact on the schedule of a construction project. Compared to traditional formwork methods, steel formwork is quicker to set up and dismantle, reducing the time required for formwork installation and removal. This efficiency allows for faster construction progress, enabling the project to stay on schedule or even be completed ahead of time. Additionally, steel formwork is highly durable and can be reused multiple times, further saving time by eliminating the need for constant formwork replacement.

Send your message to us

Steel Coupler Rebar Scaffolding Outrigger Concrete Slab Formwork Scaffolding System High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords