Concrete Pump Truck Parts Bend DN125 R1000 90DRG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you.

We can supply OEM service and can also produce according to your requirements.

Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

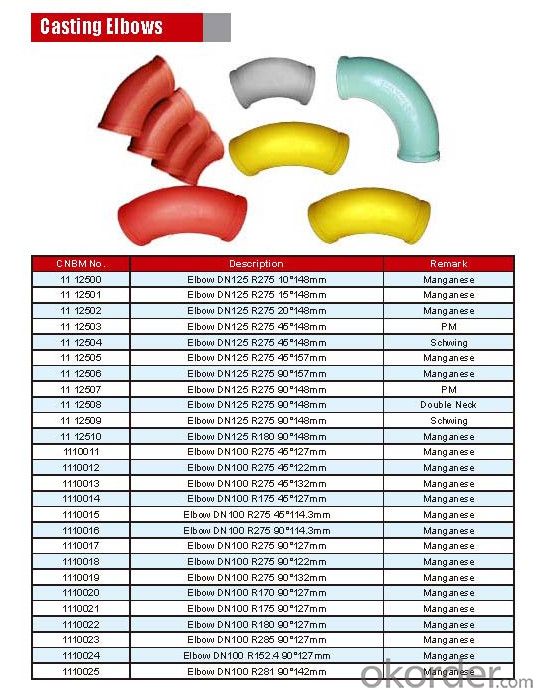

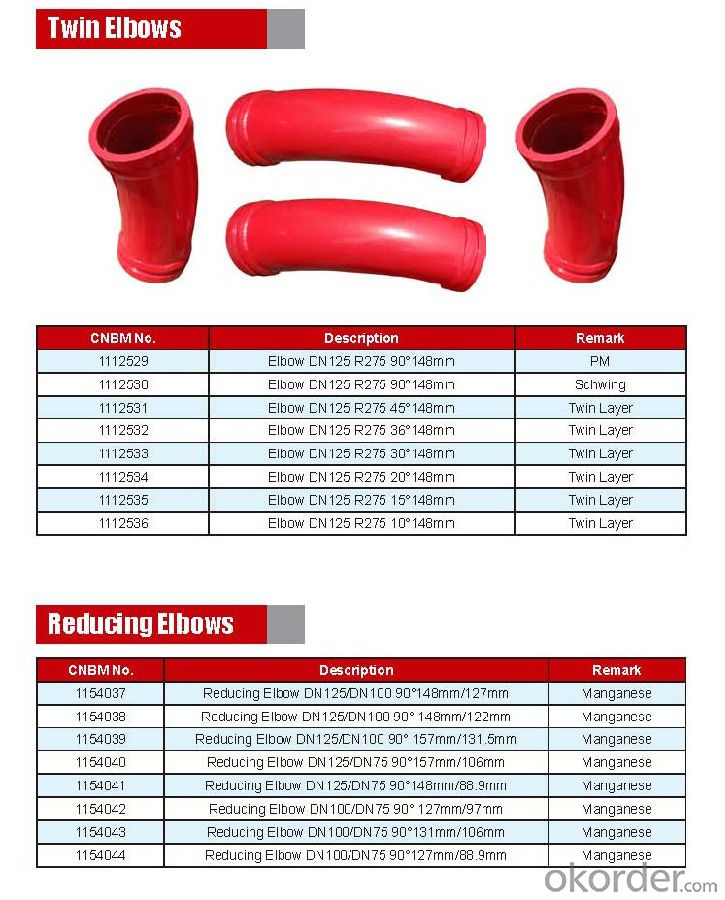

Product Specifications:

Technical: Casting

Radius: 1000mm

Degree: 90

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Concrete pump spare parts can undergo pre-assembly and pre-testing prior to installation. This allows for quality control measures to be implemented before the actual installation takes place, ensuring that any defects or issues with the parts can be identified and resolved before they are put into the concrete pump. Furthermore, pre-testing the spare parts guarantees their functionality and compatibility with the pump system, enabling any necessary adjustments or modifications to be made in advance. By engaging in these practices, the risk of complications during the installation process is reduced, resulting in a smooth and efficient operation of the pump system.

- Q: Are there any specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts. These guidelines typically vary depending on local regulations and environmental laws. It is generally recommended to follow the manufacturer's instructions for proper disposal methods. This may involve recycling the hydraulic fluids or disposing of them at designated waste management facilities to ensure minimal environmental impact.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Yes, there are specific maintenance practices that should be followed for concrete pump spare parts. Firstly, it is important to regularly inspect the spare parts for any signs of wear or damage. This includes checking for cracks, leaks, or any other visible defects. If any issues are detected, the spare parts should be replaced or repaired immediately to prevent further damage. Secondly, it is crucial to clean the spare parts on a regular basis. Concrete pump spare parts often come into contact with cement, water, and other substances that can cause build-up and affect their performance. Regular cleaning will help remove any debris or residue, ensuring that the spare parts function optimally. Additionally, lubrication is an essential maintenance practice for concrete pump spare parts. Lubricating moving components such as bearings, seals, and pistons will help reduce friction and wear, extending the lifespan of the spare parts. It is important to use the correct lubricants specified by the manufacturer and follow their guidelines for application. Furthermore, proper storage of spare parts is also important for their maintenance. They should be stored in a clean and dry environment, away from any chemicals or other substances that could damage them. Spare parts should also be stored in a way that protects them from physical damage, such as being dropped or bumped. Lastly, it is recommended to follow the manufacturer's guidelines and recommendations for maintenance and replacement intervals. Regular servicing and inspections by qualified technicians can help identify any potential issues early on and prevent major breakdowns or failures. In conclusion, following specific maintenance practices such as regular inspection, cleaning, lubrication, proper storage, and adherence to manufacturer's guidelines are crucial for ensuring the optimal performance and longevity of concrete pump spare parts.

- Q: What are the preventive measures for concrete pump?

- First, the ratio of the maximum particle size to the diameter of the coarse aggregate should be determined

- Q: Can concrete pump spare parts be retrofitted to older pump models?

- Indeed, older pump models can often accommodate retrofitting of concrete pump spare parts. Multiple manufacturers engineer their spare parts to be compatible with various pump models, even those from previous generations. Nonetheless, it is crucial to acknowledge that not all spare parts may be appropriate for retrofitting, as compatibility can differ based on the specific pump model and the part in consideration. It is advisable to seek guidance from the manufacturer or a qualified technician to ascertain the compatibility and safe retrofitting of the spare parts onto older pump models.

- Q: How do I maintain the performance of concrete pump spare parts in extreme weather conditions?

- To maintain the performance of concrete pump spare parts in extreme weather conditions, it is crucial to take certain precautions. Firstly, ensure that the spare parts are properly protected from direct exposure to harsh weather elements such as rain, snow, or extreme heat. This can be achieved by using covers or shelters to shield the parts. Additionally, regular cleaning and lubrication of the spare parts will help to prevent any buildup of dust, dirt, or moisture that could potentially affect their performance. Lastly, conducting regular inspections and maintenance checks will allow for early detection of any damage or wear, enabling timely repairs or replacements to be made, thus ensuring optimal performance in extreme weather conditions.

- Q: How is the piping of the concrete pipe designed?

- When pumping underground structures, the horizontal axis of the ground shall be perpendicular to the axis of the Y - shaped discharge port

- Q: Are there any specific safety precautions for handling concrete pump spare parts?

- Concrete pump spare parts require specific safety precautions to be followed. It is essential to wear the appropriate personal protective equipment (PPE) like gloves, safety goggles, and a dust mask. This ensures protection against potential hazards, as concrete dust can harm the skin and cause respiratory issues if inhaled. Proper lifting techniques are crucial when handling these spare parts to prevent strains or injuries. Heavy parts should be lifted using lifting equipment or with the assistance of others to minimize accidents. Moreover, it is vital to handle the spare parts with care and avoid rough handling or dropping to prevent damage or breakage. Damaged spare parts can negatively impact the concrete pump's performance and safety. Storing the spare parts in a clean, dry area away from moisture or chemicals is also important. This prevents potential damage that may compromise the quality and integrity of the spare parts. Lastly, it is advisable to always follow the manufacturer's instructions and guidelines for handling concrete pump spare parts. They provide specific safety precautions and recommendations, ensuring the parts are handled and used safely. By adhering to these safety precautions, the risk of accidents, injuries, and damage to the concrete pump spare parts can be minimized, creating a safe working environment.

- Q: What is the purpose of a concrete pump piston?

- The purpose of a concrete pump piston is to pressurize and push the concrete mixture through a pipeline, enabling efficient and accurate placement of the concrete in construction projects.

- Q: What are the advantages of using stainless steel components in concrete pump spare parts?

- There are several advantages of using stainless steel components in concrete pump spare parts. Firstly, stainless steel has excellent corrosion resistance, which ensures the longevity and durability of the spare parts even in harsh environments. Secondly, stainless steel is known for its high strength-to-weight ratio, providing increased strength and reliability without adding excessive weight to the concrete pump. Additionally, stainless steel is highly resistant to wear and tear, which reduces the need for frequent replacements and maintenance. Lastly, stainless steel components offer a hygienic and clean surface, making them suitable for applications in the construction industry where cleanliness is crucial.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R1000 90DRG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords