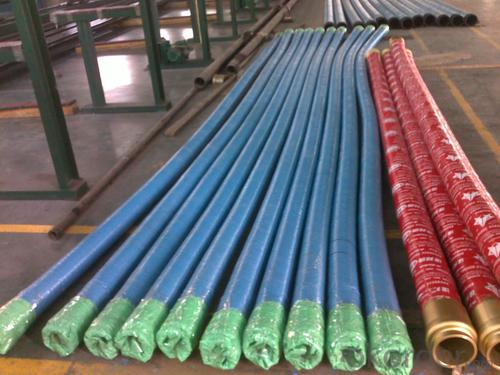

Concrete Pump Rubber End Hose DN100 with 7M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification

DN100*7M CONCRETE PUMP RUBBER HOSE

1.Work Pressure:85~1250(BAR/PSI)

2.Burst Pressure:200 to 2940(BAR/PSI)

3.Working life:20000m³

4.The inside of hose is high abrasion resistant.

5.Integrated hose end and inner wall harden,prolong work life.

Name | Concrete rubber hose; Delivery hose; End hose; Concrete pump hose; Boom hose |

Size | 2"/2.5"/3"/3.5"/4"/4.5"/5"/6"or according to client’s requirement |

Length | 3M,5 or Any length |

Reinforcement | Steel wire, tire cord or fabric |

Hose End | Galvanized, inner wall harden |

Application | Schwing, Putzmeister, Sany, Zoomlion, etc |

2. Application

1.Applacation:delivery concrete

2.Suitable for the various :Schwing, CIFA,PM, Zoomlion ,SANY and so on.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce DN100*7M CONCRETE PUMP RUBBER HOSE according to customers request?

A4: Yes, we can produce DN100*7M CONCRETE PUMP RUBBER HOSE according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: What are the layout requirements of concrete pump for building engineering?

- The concrete pump shall be as close as possible to the casting site. In the use of cloth rod work, should make the casting parts as far as possible within the working range of the distribution rod, as little as possible to move the pump, that is able to complete the pouring.

- Q: What are the performance characteristics of concrete pump?

- The use of advanced S pipe distribution valve, automatic compensation for wear clearance, good sealing performance

- Q: Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can often be retrofitted to older pump models. Many manufacturers design their spare parts to be compatible with multiple pump models, including older ones. However, it is important to note that not all spare parts may be suitable for retrofitting, as compatibility can vary depending on the specific pump model and the part in question. It is advisable to consult with the manufacturer or a qualified technician to ensure that the spare parts are compatible and can be safely retrofitted to older pump models.

- Q: How do I properly maintain and replace hydraulic pumps in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic pumps in concrete pump spare parts involve a few key steps. Firstly, it is crucial to regularly inspect the hydraulic pump for any signs of wear, leaks, or damage. This includes checking the fluid levels, filters, and hoses. Secondly, following the manufacturer's guidelines, ensure that the hydraulic pump is regularly serviced and that the recommended maintenance tasks are performed on schedule. This includes changing the hydraulic fluid, replacing filters, and lubricating moving parts. Lastly, when it comes to replacing hydraulic pumps, it is important to use genuine and compatible spare parts that are recommended by the manufacturer. Additionally, it is advisable to seek professional assistance or consult the manufacturer's instructions to ensure proper installation and alignment of the new pump.

- Q: What is the first generation pumping technology of concrete pump?

- The machine assembly is simple and the production cost is low, but the electrical control is complex

- Q: What are the signs of a damaged or malfunctioning electric motor?

- There are several signs that indicate a damaged or malfunctioning electric motor. Firstly, unusual noises such as grinding, squealing, or banging sounds are typically indicative of a problem. These sounds may suggest that the motor's bearings are worn out or that there is an issue with the motor's internal components. Secondly, excessive heat is another sign of a damaged electric motor. If the motor feels unusually hot to the touch, it could signify that the motor is working harder than it should be or that there is a problem with its cooling system. Thirdly, a motor that frequently trips the circuit breaker or blows fuses is a clear indication of a malfunction. This could be due to an electrical fault within the motor or an overload caused by a faulty component. Furthermore, a damaged electric motor may exhibit decreased performance or a noticeable decrease in power output. This could be observed as a decrease in speed or torque produced by the motor, or even a complete inability to start or function properly. Lastly, excessive vibration or shaking of the motor could indicate misalignment or an issue with the motor's mounting. This can lead to further damage if not addressed promptly. If any of these signs are observed, it is recommended to immediately stop using the motor and consult a qualified technician or electrician to diagnose and repair the problem. Ignoring or continuing to use a damaged motor can lead to further damage and potentially dangerous situations.

- Q: How often should hopper agitator blades be inspected or replaced in a concrete pump?

- Hopper agitator blades in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure that they are functioning properly. Replacement of the blades should be done as necessary, depending on the wear and tear they have undergone.

- Q: How can a faulty concrete pump control valve affect the pumping operation?

- A faulty concrete pump control valve can adversely affect the pumping operation in several ways. Firstly, it may lead to an inconsistent flow of concrete, causing disruptions in the pouring process. This can result in uneven distribution of concrete, affecting the quality and structural integrity of the project. Secondly, a faulty control valve may cause excessive pressure build-up within the pump, leading to potential damages or leaks. Additionally, it can impact the overall efficiency and productivity of the pumping operation, resulting in delays and increased costs. Therefore, it is crucial to ensure that the concrete pump control valve is in proper working condition to maintain a smooth and efficient pumping process.

- Q: How does a concrete pump clamp work?

- An integral part of a concrete pump is the concrete pump clamp, which is utilized to securely fasten and stabilize the concrete delivery pipeline. Its function is to firmly grasp the pipeline, eliminating any potential movement or leakage throughout the concrete pumping procedure. Typically comprised of two primary components, the concrete pump clamp consists of the clamp body and the wedge. The clamp body, constructed from durable steel, possesses a curved structure tailored to the pipeline's shape. Equipped with bolts or knobs, it can be tightened or loosened to attach the clamp to the pipeline. In contrast, the wedge is a metal piece that is inserted into the clamp body. Its purpose is to apply pressure to the pipeline when the clamp is tightened. By manipulating the bolts or knobs, the wedge is pushed deeper into the clamp body, effectively squeezing the pipeline and establishing a secure grip. The secure grip achieved by the concrete pump clamp is essential as it guarantees a seamless and uninterrupted flow of concrete without any leaks or disruptions. It upholds a consistent and steady movement of concrete from the pump to the desired destination. Furthermore, the clamp contributes to the stability of the pipeline, preventing any shifting or displacement during the pumping process. In summary, the concrete pump clamp assumes a crucial role in the efficient and safe operation of a concrete pump. It ensures the secure placement of the concrete delivery pipeline, facilitating a smooth and uninterrupted concrete pumping process.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When buying spare parts for a concrete pump, there are several important factors to think about. These factors include making sure that the spare parts are compatible with the concrete pump's make and model, checking their quality and reliability, ensuring their availability, and considering their cost-effectiveness. First and foremost, it is crucial to make sure that the spare parts you purchase are suitable for the concrete pump you have. Concrete pumps come in different makes and models, and each may have specific requirements for spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts you buy to ensure proper functionality and performance. The quality and reliability of the spare parts are also important considerations. Investing in high-quality spare parts can have a significant impact on the efficiency and lifespan of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Doing thorough research and reading customer reviews can help assess the quality and reliability of the spare parts. Availability is another crucial factor to consider when purchasing spare parts for a concrete pump. It is important to ensure that the spare parts you need are easily accessible, either from local suppliers or through efficient delivery channels. Delays in obtaining the necessary spare parts can result in extended downtime and increased costs. Therefore, it is recommended to choose suppliers with a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when buying spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help make a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key factors, you can ensure that the spare parts you choose will meet the specific needs of your concrete pump, maintain its performance and reliability, and provide value for your money.

Send your message to us

Concrete Pump Rubber End Hose DN100 with 7M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords