Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump elbows have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Adopt high chromium and manganese as standard material, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.Two production lines, wear-resistant pipe 100pcs daily, trailer pipe 400pcs daily.

2. The experiment done abroad shows that the life of our concrete pump pipes can reach 6000-15000cbm,got the customers' praise. Uniform baking finish.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. Normal and female/male flanges are both available to suit for normal or high pressure concrete pumping

5. OEM service available.

6. Fitting to PUTZMEISTER, SCHWING Sany, Zoomlion concrete pumps

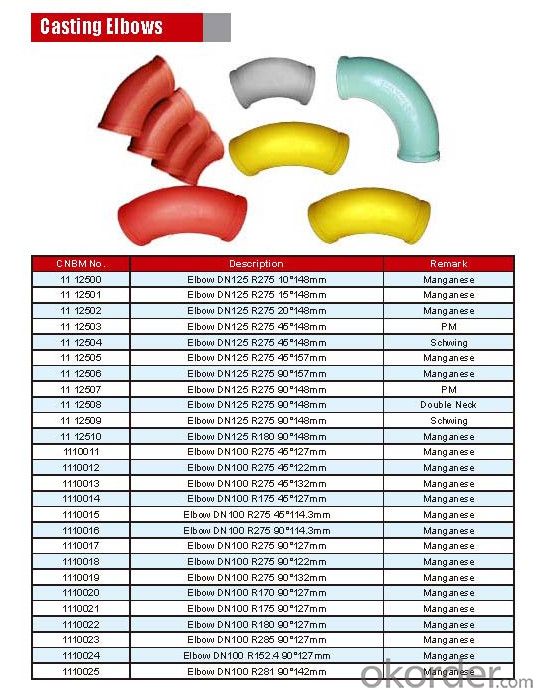

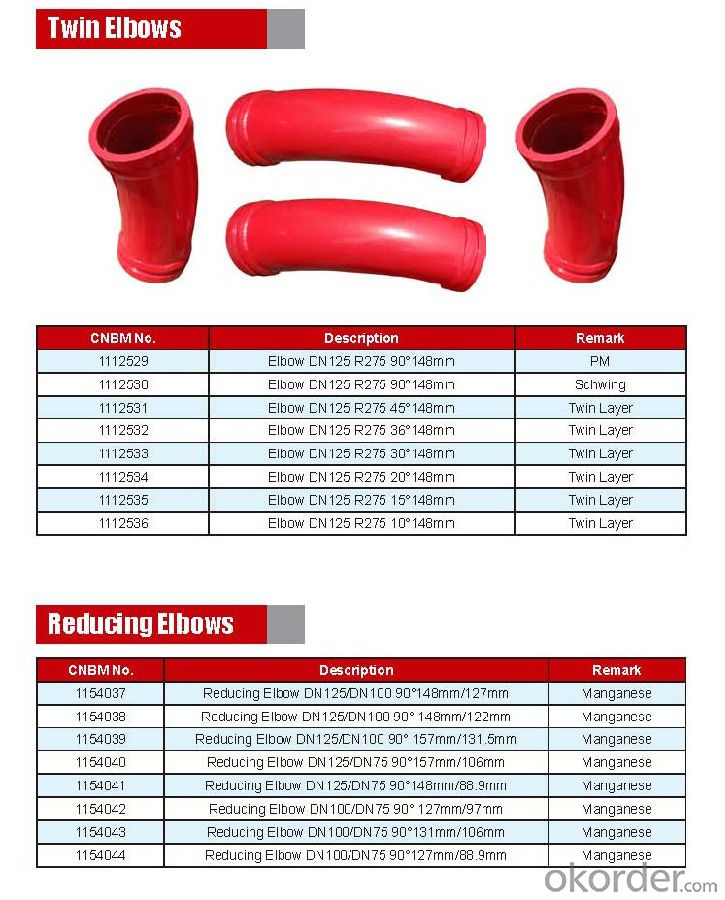

Product Specifications:

Technical: Casting

Radius: 1000mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: How often should concrete pump control panels be inspected and replaced?

- Concrete pump control panels should be inspected regularly to ensure they are functioning properly and to identify any potential issues or malfunctions. The frequency of inspections may vary depending on several factors such as the type of pump, the operating conditions, and the manufacturer's recommendations. However, a general guideline is to have a thorough inspection at least once every six months or after every 500 hours of operation, whichever comes first. During these inspections, trained professionals should check for any signs of wear or damage on the control panel components, including buttons, switches, indicators, and wiring. They should also verify the functionality of the control panel by testing all the different functions and safety features. In terms of replacement, it is essential to follow the manufacturer's guidelines and recommendations. Typically, control panels have a lifespan of several years, but this will depend on various factors such as the quality of the panel, frequency of use, and maintenance practices. If any significant issues or failures are identified during inspections, it is important to replace the control panel promptly to ensure the safe and efficient operation of the concrete pump. Ultimately, regular inspections and prompt replacement of control panels are crucial to minimize the risk of equipment failure, ensure safety on the construction site, and maintain the productivity and longevity of the concrete pump.

- Q: How do I properly maintain and replace hydraulic cylinders in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic cylinders in concrete pump spare parts is crucial for ensuring the smooth functioning and longevity of your equipment. Here are some steps to help you with this process: 1. Regular Inspection: Conduct regular inspections of the hydraulic cylinders to check for any signs of wear, leaks, or damage. Look for any fluid leakage, rust, or dents in the cylinder body or rod. Inspect the seals, piston, and rod for any signs of wear or damage. 2. Cleanliness: Keep the hydraulic cylinders and their components clean. Dirt and debris can cause damage and reduce the efficiency of the system. Regularly wipe down the cylinders and ensure that there is no build-up of dirt or debris. 3. Lubrication: Proper lubrication is essential for the smooth operation of hydraulic cylinders. Follow the manufacturer's recommendations for lubrication intervals and use the appropriate lubricants. Make sure to apply the lubricant to all moving parts, seals, and fittings. 4. Fluid Checks: Check the hydraulic fluid regularly to ensure that it is at the correct level and is free from contaminants. If the fluid appears dirty or contaminated, it should be replaced. Additionally, check the hydraulic filter and replace it if necessary. 5. Seals and O-rings: Inspect the seals and O-rings in the hydraulic cylinders for any signs of wear or damage. Replace them if necessary to prevent leaks and maintain optimal performance. 6. Replacing Hydraulic Cylinders: When replacing hydraulic cylinders, it is important to follow the manufacturer's instructions and guidelines. Ensure that you have the correct replacement cylinder for your specific model and application. Properly align the cylinder during installation and tighten all bolts and connections to the recommended torque specifications. 7. Testing: After replacing hydraulic cylinders, test the system for any leaks or abnormal operation. Check for smooth and consistent movement of the cylinder and ensure that there are no fluid leaks or unusual noises. 8. Professional Assistance: If you are unsure about any aspect of maintaining or replacing hydraulic cylinders, it is recommended to seek the assistance of a professional. They will have the expertise and experience to ensure that the job is done correctly and safely. By following these steps and maintaining a regular maintenance schedule, you can ensure the proper functioning and longevity of hydraulic cylinders in your concrete pump spare parts.

- Q: How can one determine the correct pressure and flow rating for hydraulic components in concrete pump spare parts?

- When determining the correct pressure and flow rating for hydraulic components in concrete pump spare parts, several factors should be taken into account: 1. Review the manufacturer's specifications for the hydraulic components. These specifications should provide the recommended pressure and flow ratings for optimal performance and durability. 2. Assess the concrete pump system's specific requirements. Factors such as pump size, concrete volume and distance, and required delivery speed should be considered. These factors will help determine the necessary pressure and flow rating for the hydraulic components. 3. Ensure that the pressure and flow rating of the hydraulic components fall within the safe operating limits of the concrete pump system. Going beyond these limits can result in equipment failure, accidents, or component damage. 4. Verify the compatibility of the hydraulic components with the rest of the system. The pressure and flow rating should align with the capabilities and specifications of other components like the pump, valves, and hoses to guarantee proper functionality and performance. 5. If unsure about the appropriate pressure and flow rating, seek guidance from hydraulic system experts or the manufacturer's technical support team. They can offer advice based on their expertise and experience with similar systems. It's important to note that the pressure and flow rating of hydraulic components may vary depending on the specific model, design, and intended application. Therefore, referring to the manufacturer's guidelines and recommendations is crucial to accurately determine the correct pressure and flow rating for hydraulic components in concrete pump spare parts.

- Q: What are the different types of concrete pump hydraulic filters?

- Construction projects commonly utilize various types of concrete pump hydraulic filters. These filters are crucial for ensuring the hydraulic system's smooth operation and longevity. 1. Suction filters, located at the hydraulic pump's intake side, play a vital role in removing larger particles and debris from the hydraulic oil. They prevent contaminants from entering the pump and causing harm to its components. 2. Positioned on the return line, return line filters are designed to eliminate smaller particles and contaminants from the hydraulic oil before it is returned to the reservoir. By maintaining oil cleanliness, they prevent system wear and tear. 3. Pressure line filters, typically installed after the hydraulic pump on the high-pressure side, remove fine particles and contaminants from the oil. Their purpose is to guarantee the valves, cylinders, and other hydraulic components work smoothly. 4. In-tank filters are submerged in the hydraulic oil reservoir to filter the oil as it circulates through the tank. They effectively eliminate larger particles and contaminants settled at the bottom of the reservoir. 5. Magnetic filters attract and remove metallic particles, such as iron filings and metal shavings, from the hydraulic oil. They are highly effective in capturing ferrous contaminants. 6. Breather filters, installed on the breather vent of the hydraulic oil reservoir, maintain the cleanliness and integrity of the hydraulic oil by preventing dust, dirt, and moisture from entering the system. Regular inspection and replacement of these hydraulic filters are crucial for optimal performance and longevity of the concrete pump's hydraulic system. Neglecting this maintenance can lead to increased wear and tear, decreased efficiency, and potential damage to the pump and its components.

- Q: How often should hopper cylinder seals be replaced in a concrete pump?

- The frequency at which hopper cylinder seals should be replaced in a concrete pump depends on several factors such as the quality of the seals, the intensity of usage, and the maintenance practices followed. Ideally, hopper cylinder seals should be inspected regularly for any signs of wear and tear or damage. If there are visible cracks, tears, or leaks, it is recommended to replace the seals as soon as possible to prevent any further damage to the concrete pump. In general, hopper cylinder seals can last anywhere from several months to a couple of years, depending on the aforementioned factors. However, it is essential to establish a preventive maintenance plan and regularly monitor the condition of the seals to ensure optimal performance and minimize downtime. Additionally, it is advisable to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for hopper cylinder seals based on the pump model, usage patterns, and environmental conditions.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The frequency at which carbide wear plates should be replaced in a concrete pump depends on several factors, including the type and quality of the plates, the intensity of usage, and the specific conditions in which the pump operates. Carbide wear plates are designed to endure heavy wear and tear caused by the abrasive nature of concrete. Generally, they have a longer lifespan compared to traditional steel wear plates. However, they are not completely immune to deterioration and will eventually wear down over time. A good rule of thumb is to regularly inspect the wear plates and monitor their condition. If the plates show signs of significant wear, such as visible cracks, excessive erosion, or reduced performance in terms of concrete flow, it is time to consider replacing them. In some cases, wear plates may need to be replaced annually, while in others, they may last several years. To prolong the lifespan of carbide wear plates, proper maintenance and care are essential. This includes regularly cleaning the plates, ensuring proper lubrication of the pump, and avoiding excessive pressure or abuse during operation. Regular maintenance can help to extend the lifespan of the wear plates and reduce the frequency of replacements. It is always recommended to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for carbide wear plates in a particular pump model. They will have the expertise and knowledge to provide accurate recommendations based on the specific conditions and usage of the concrete pump.

- Q: How can a faulty electric motor affect the pump's performance?

- The performance of the pump can be significantly affected by a defective electric motor. To begin with, the motor is responsible for supplying the necessary power to operate the pump. If the motor is faulty, it may fail to generate the required amount of power, leading to a decline in the pump's performance and efficiency. This can result in decreased flow rates and lower pressure output, which in turn hampers the pump's functioning. Furthermore, a defective motor can also give rise to problems such as increased energy consumption and overheating. In case the motor is not working properly, it may consume excessive electrical current, resulting in higher energy usage and elevated operational costs. Moreover, an overheating motor can cause damage to the pump and other associated components, thereby further affecting performance and potentially leading to expensive repairs or replacements. Moreover, the reliability and lifespan of the pump can also be compromised by a defective motor. Operating the pump continuously with a faulty motor can subject it to excessive strain, resulting in premature wear and tear, heightened maintenance requirements, and a shorter lifespan. Consequently, frequent breakdowns, downtime, and a decline in overall productivity may occur. In conclusion, a defective electric motor can have various adverse effects on the pump's performance, including reduced flow rates, diminished pressure output, increased energy consumption, overheating, and decreased reliability. Therefore, it is crucial to regularly inspect and maintain motors to ensure their optimal functioning and prevent any detrimental impact on the pump's performance.

- Q: What are the precautions for gas washing of concrete pump?

- Compressed air pressure shall not be higher than 0.7MPa

- Q: How often should hydraulic oil filters be replaced in a concrete pump?

- The replacement frequency of hydraulic oil filters in a concrete pump is determined by several factors, such as operating conditions, oil type, and manufacturer recommendations. It is generally advised to replace these filters every 500 to 1000 operating hours or every 6 to 12 months, depending on which comes first. However, it is crucial to refer to the concrete pump's operation manual or the manufacturer's guidelines to determine the exact replacement interval for the hydraulic oil filters. Monitoring the filter's condition regularly and conducting routine maintenance checks can also aid in identifying the need for an earlier filter replacement than the recommended interval.

- Q: Can I get spare parts for concrete pump hoppers and agitators?

- Yes, it is possible to get spare parts for concrete pump hoppers and agitators. Many manufacturers and suppliers of concrete pumps and equipment offer spare parts for their products. You can contact the manufacturer or supplier of your specific concrete pump hopper or agitator to inquire about the availability and pricing of spare parts. Additionally, there are also specialized companies that provide spare parts for various brands and models of concrete pumps and equipment. These companies typically have a wide range of spare parts in stock and can ship them to you as needed.

Send your message to us

Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords