Concrete Pump Truck Parts Bend DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump elbows have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.Two production lines, wear-resistant pipe 100pcs daily, trailer pipe 400pcs daily.

2. The experiment done abroad shows that the life of our concrete pump pipes can reach 6000-15000cbm,got the customers' praise.Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. OEM service available.

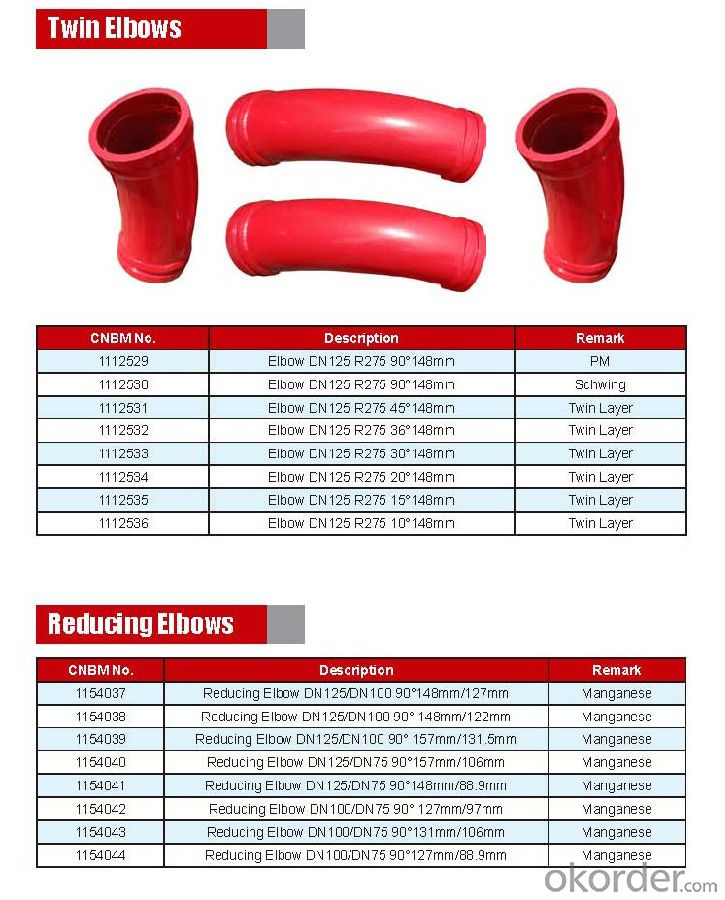

5. Applications: Putzmeister, Schwing, Zoomlion, SANY, etc.

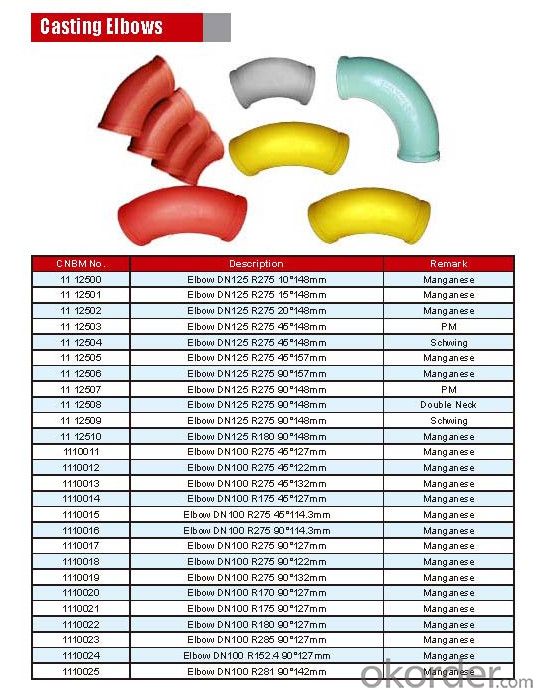

Product Specifications:

Technical: Casting

Radius: 500mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: How can a faulty water pump affect the concrete pumping operation?

- A faulty water pump can have several negative effects on a concrete pumping operation. Firstly, a water pump is responsible for supplying water that is used to mix the concrete and maintain its proper consistency. If the water pump is faulty and not functioning correctly, it may not be able to supply the required amount of water, resulting in the concrete mix being too dry or not well-mixed. This can lead to a poor-quality concrete mix that is difficult to pump and may not set properly, compromising the structural integrity of the concrete. Additionally, a faulty water pump can affect the efficiency and productivity of the concrete pumping operation. If the pump is not working efficiently, it may take longer to mix and deliver the concrete, causing delays in the construction process. This can lead to increased costs and potential disruptions to project timelines. Furthermore, a faulty water pump can also impact the safety of the concrete pumping operation. Adequate water supply is essential for preventing the concrete from overheating during the pumping process. If the water pump fails to supply enough water, the concrete can heat up rapidly, leading to a phenomenon called thermal cracking. Thermal cracking weakens the concrete and can cause it to fail prematurely, posing a safety risk to workers and the overall structure. In summary, a faulty water pump can negatively impact a concrete pumping operation by resulting in poor-quality concrete mixes, decreased efficiency and productivity, and potential safety hazards. It is crucial to regularly inspect and maintain water pumps to ensure their proper functioning and prevent any detrimental effects on the concrete pumping process.

- Q: Can concrete pump spare parts be inspected or certified by third-party organizations?

- Yes, concrete pump spare parts can be inspected and certified by third-party organizations. These organizations are typically independent and have the expertise and resources to evaluate the quality, performance, and safety of the spare parts. They follow specific industry standards and guidelines to conduct inspections, tests, and audits to determine if the spare parts meet the necessary requirements. The certification provided by these third-party organizations gives assurance to customers that the spare parts have been assessed and found to be in compliance with the applicable standards. This helps to enhance trust and confidence in the products, ensuring that they are reliable and suitable for use in concrete pumps.

- Q: Are there any specific guidelines for the disposal of old or damaged concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of old or damaged concrete pump spare parts. It is important to properly dispose of these parts to ensure environmental sustainability and to adhere to local regulations. Here are some guidelines to follow: 1. Identify hazardous materials: Before disposing of any concrete pump spare parts, it is crucial to determine if they contain any hazardous materials such as oils, lubricants, or chemicals. These substances require special handling and cannot be disposed of in regular waste streams. 2. Separate recyclable materials: If the spare parts are made of materials that can be recycled, such as metal or plastic, it is recommended to separate them from other waste. Recycling these materials helps in conserving resources and reducing the strain on landfill sites. 3. Contact local waste management authorities: Different regions have different guidelines and regulations for the disposal of specific materials. It is advisable to get in touch with the local waste management authorities to understand the proper procedures for disposing of concrete pump spare parts in your area. 4. Arrange for proper disposal: Once you have identified any hazardous materials and separated recyclable parts, arrange for their proper disposal. This may involve contacting specialized waste management companies that can handle hazardous materials or taking them to designated recycling centers. 5. Avoid illegal dumping: It is essential to avoid illegal dumping of old or damaged concrete pump spare parts. This can harm the environment and may result in fines or penalties. Always dispose of these parts through legal and responsible channels. By following these guidelines, you can ensure the proper disposal of old or damaged concrete pump spare parts, minimize the impact on the environment, and comply with local regulations.

- Q: How do I properly maintain and replace hydraulic cylinders in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic cylinders in concrete pump spare parts is crucial for ensuring the smooth functioning and longevity of your equipment. Here are some steps to help you with this process: 1. Regular Inspection: Conduct regular inspections of the hydraulic cylinders to check for any signs of wear, leaks, or damage. Look for any fluid leakage, rust, or dents in the cylinder body or rod. Inspect the seals, piston, and rod for any signs of wear or damage. 2. Cleanliness: Keep the hydraulic cylinders and their components clean. Dirt and debris can cause damage and reduce the efficiency of the system. Regularly wipe down the cylinders and ensure that there is no build-up of dirt or debris. 3. Lubrication: Proper lubrication is essential for the smooth operation of hydraulic cylinders. Follow the manufacturer's recommendations for lubrication intervals and use the appropriate lubricants. Make sure to apply the lubricant to all moving parts, seals, and fittings. 4. Fluid Checks: Check the hydraulic fluid regularly to ensure that it is at the correct level and is free from contaminants. If the fluid appears dirty or contaminated, it should be replaced. Additionally, check the hydraulic filter and replace it if necessary. 5. Seals and O-rings: Inspect the seals and O-rings in the hydraulic cylinders for any signs of wear or damage. Replace them if necessary to prevent leaks and maintain optimal performance. 6. Replacing Hydraulic Cylinders: When replacing hydraulic cylinders, it is important to follow the manufacturer's instructions and guidelines. Ensure that you have the correct replacement cylinder for your specific model and application. Properly align the cylinder during installation and tighten all bolts and connections to the recommended torque specifications. 7. Testing: After replacing hydraulic cylinders, test the system for any leaks or abnormal operation. Check for smooth and consistent movement of the cylinder and ensure that there are no fluid leaks or unusual noises. 8. Professional Assistance: If you are unsure about any aspect of maintaining or replacing hydraulic cylinders, it is recommended to seek the assistance of a professional. They will have the expertise and experience to ensure that the job is done correctly and safely. By following these steps and maintaining a regular maintenance schedule, you can ensure the proper functioning and longevity of hydraulic cylinders in your concrete pump spare parts.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. Regular cleaning of the spare parts is necessary to remove any dirt, debris, or concrete buildup that may affect their performance. This can be done using water, mild detergent, and a brush to scrub the parts gently. Additionally, lubrication of moving parts and regular inspection for wear and tear is crucial to ensure optimal functioning and longevity of the spare parts.

- Q: What are the fittings of concrete pump?

- Fine stone concrete pump parts are: main oil cylinder, concrete cylinder, three-phase asynchronous motor, main oil pump, hopper, S pipe, electric distribution cabinet, hand oil pump, piston

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To guarantee the compatibility of mechanical components in concrete pump spare parts, there are several essential measures you can take: 1. Determine the exact make and model of your concrete pump: Different concrete pumps may have different designs and specifications, so it is crucial to identify the specific make and model of your pump. This information will assist you in selecting the appropriate spare parts for your particular pump. 2. Review the manufacturer's documentation: Examine the manufacturer's documentation, which includes the user manual and parts catalog, to understand the recommended spare parts for your concrete pump. These documents typically provide detailed information on the compatibility of various mechanical components. 3. Seek guidance from the manufacturer or authorized dealers: If you have doubts about the compatibility of certain mechanical components, it is advisable to consult the manufacturer or authorized dealers. They possess extensive knowledge and experience with their products and can offer advice on choosing compatible spare parts. 4. Consider utilizing OEM (Original Equipment Manufacturer) parts: OEM parts are specifically designed and manufactured by the original equipment manufacturer. Employing OEM parts ensures the highest level of compatibility and reliability. Although they may be slightly more expensive than aftermarket alternatives, they often provide superior performance and longer service life. 5. Verify standardized sizing and specifications: Mechanical components, such as seals, gaskets, and bearings, frequently adhere to standardized sizes and specifications. Ensure that the spare parts you are considering match these standardized measurements to guarantee compatibility. 6. Conduct thorough research and comparison: Prior to purchasing spare parts, conduct research on various suppliers and compare their offerings. Look for reputable suppliers who specialize in concrete pump spare parts and have a proven track record of delivering high-quality, compatible components. 7. Perform compatibility testing: If you are unsure about the compatibility of a specific mechanical component, consider conducting compatibility tests. This may involve installing the spare part in your concrete pump and assessing its fit, function, and performance. If possible, seek assistance from a qualified mechanic or technician to assist you with these tests. By following these steps, you can ensure the compatibility of mechanical components in concrete pump spare parts, minimizing the risk of compatibility issues and ensuring the smooth operation and maintenance of your concrete pump.

- Q: How often should hydraulic pumps be inspected or replaced in a concrete pump?

- Hydraulic pumps in a concrete pump should be inspected regularly, ideally every 500 hours of operation or at least once a year. However, the frequency of replacement depends on various factors such as the quality of the pump, maintenance practices, and the intensity of use. It is crucial to monitor the pump's performance, fluid levels, and any signs of wear or damage to determine if replacement is necessary.

- Q: Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control panels or electronic components in concrete pump spare parts. These guidelines typically recommend ensuring proper grounding, protection from moisture and vibration, and compliance with electrical codes and safety standards. It is crucial to follow these guidelines to ensure the efficient and safe operation of the equipment.

- Q: How often should hydraulic oil filters be replaced in a concrete pump?

- Hydraulic oil filters in a concrete pump should be replaced regularly according to the manufacturer's recommendations. Typically, it is recommended to replace hydraulic oil filters every 500 to 1,000 hours of operation or annually, whichever comes first. However, the specific replacement frequency may vary based on factors such as the operating conditions, environment, and the quality of hydraulic oil used. Regular maintenance and monitoring of the filter's condition can help determine the appropriate replacement interval to ensure efficient and reliable performance of the concrete pump.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords