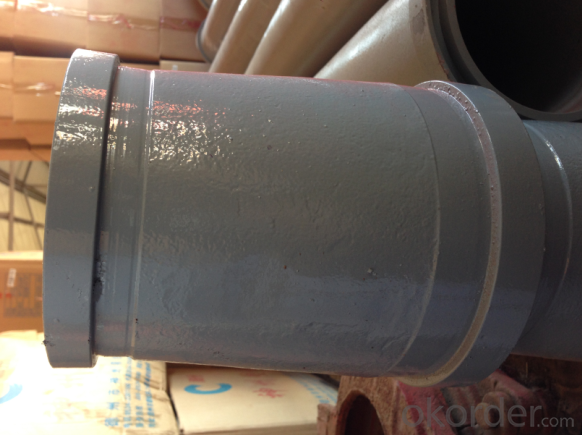

Concrete Pump Truck Parts Bend DN125 R500 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery bend connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

Two production lines, wear-resistant bend 100pcs daily, trailer bends 400pcs daily.

Seaworthy packing or as customers’ request. Service life:6000-15000 CBM Concrete.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you./ We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market.

We can supply OEM service and can also produce according to your requirements.

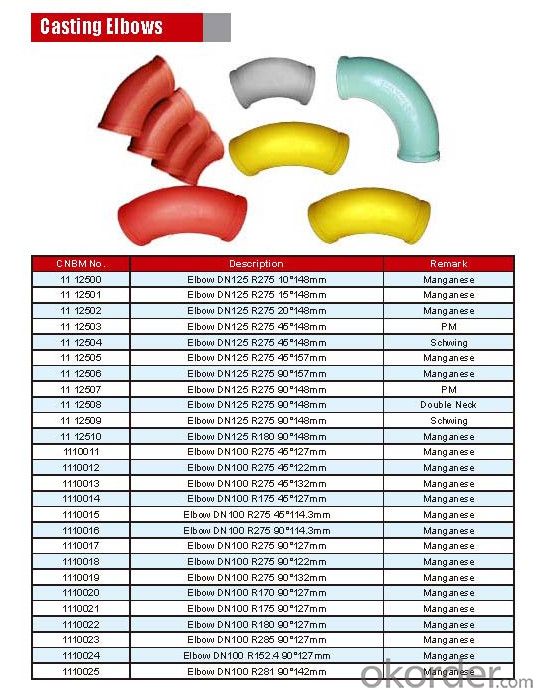

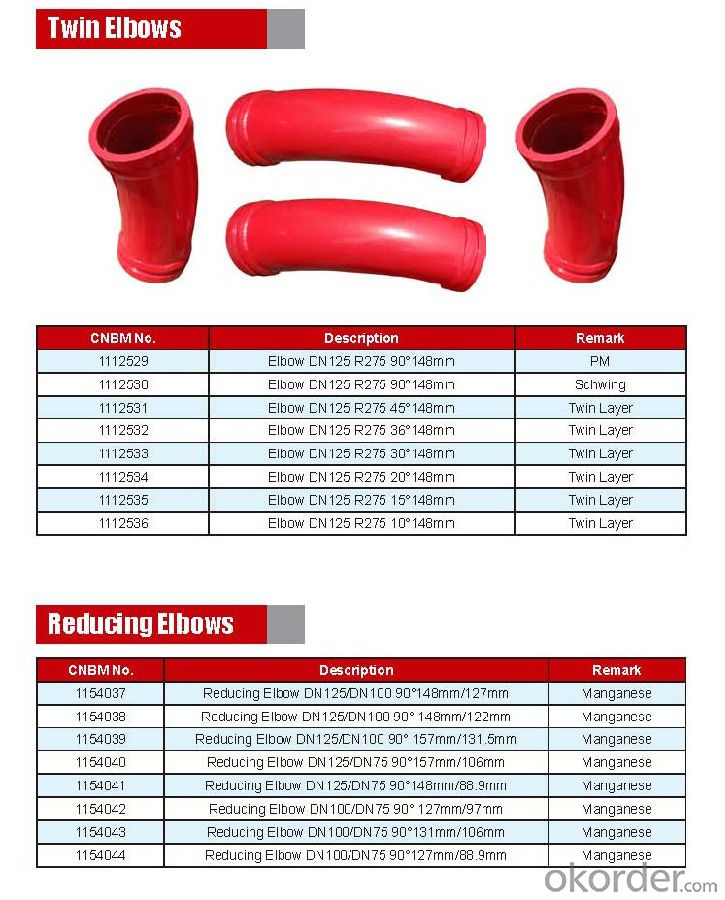

Applications: Putzmeister, Schwing, Zoomlion, SANY, etc.

Product Specifications:

Technical: Casting

Radius: 500mm

Degree: 90

Material: Mn13-4

Characteristics: According to our technology, the casting bends also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: Where can I buy concrete pump spare parts?

- There are several places where you can buy concrete pump spare parts. One option is to check with the manufacturer of your concrete pump. They usually have authorized dealers or distributors that sell genuine spare parts for their equipment. This ensures the quality and compatibility of the parts with your specific pump model. Another option is to look for specialized construction equipment suppliers or dealers in your area. These companies often carry a wide range of spare parts for various types and brands of concrete pumps. You can visit their physical stores or check their websites to see if they have the specific parts you need. Online marketplaces and platforms are also a convenient option for purchasing concrete pump spare parts. Websites like Amazon, eBay, and Alibaba have a vast selection of spare parts from different sellers worldwide. You can compare prices, read reviews, and choose the parts that best suit your needs. Before making a purchase, it is essential to ensure that you are buying from a reputable source. Look for sellers with positive feedback or ratings, and check if they offer warranties or return policies. Additionally, consider factors like shipping costs, delivery times, and customer service when deciding where to buy your concrete pump spare parts.

- Q: Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Absolutely, spare parts for concrete pump hydraulic cylinders and valves are readily available. There is a wide range of companies and suppliers dedicated to supplying spare parts specifically for construction machinery, such as hydraulic cylinders and valves for concrete pumps. These spare parts can be conveniently obtained online or through nearby distributors. To ensure compatibility and proper operation of the spare parts, it is crucial to provide precise details about the make and model of your concrete pump. Furthermore, it is recommended to select reputable suppliers who offer authentic, top-notch spare parts for optimal performance and longevity.

- Q: What are the different types of concrete pump hopper agitator shaft seals?

- There are various types of concrete pump hopper agitator shaft seals, including packing seals, mechanical seals, and lip seals.

- Q: Can a concrete pump wear plate be repaired or does it need to be replaced entirely?

- In certain situations, a concrete pump wear plate may require repair or complete replacement. The determination of whether to repair or replace the wear plate depends on the extent of the damage and the overall condition of the plate. In the case of minor damages such as small cracks, dents, or worn out areas, suitable techniques can often be employed for repair. For instance, small cracks can be welded or filled with an appropriate epoxy or filler material. Similarly, dents or worn out areas can be filled and smoothed to restore the plate's functionality. However, if the wear plate has sustained significant damage, such as extensive cracks, severe corrosion, or large holes, it may be more advisable to replace the plate entirely. This is due to the potential compromise in the structural integrity and effectiveness of the wear plate if extensive damage is repaired. Optimal performance and safety of the concrete pump can be ensured by replacing the wear plate in these cases. Careful assessment of the wear plate's condition is crucial before deciding to repair or replace it. Seeking guidance from experts or professionals knowledgeable in concrete pump maintenance can provide valuable insights in making the appropriate decision. Additionally, regular maintenance and inspection of the wear plate can help detect potential issues early on, enabling timely repairs or replacements to prevent further damage and ensure the efficient operation of the concrete pump.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. Here are some general guidelines to follow: 1. Safety precautions: Always ensure that the concrete pump is turned off and depressurized before attempting to install any seal kits or O-rings. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the installation process. 2. Preparation: Thoroughly clean the area where the seal kits or O-rings will be installed. Remove any debris or old seal remnants to ensure a clean and smooth surface for installation. 3. Inspection: Before installing new seal kits or O-rings, inspect them for any defects or damage. If any issues are found, replace the faulty parts with new ones. 4. Lubrication: Apply a small amount of compatible lubricant or hydraulic oil to the seal kits or O-rings to aid in their installation and prevent damage during the process. Be sure to use a lubricant that is compatible with the materials used in the seal kits or O-rings. 5. Proper alignment: Carefully align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Ensure that they are properly seated and positioned before proceeding. 6. Correct installation technique: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid excessive force or bending, as this can lead to damage or improper sealing. 7. Testing: After the installation is complete, test the concrete pump to ensure that the seal kits or O-rings are functioning properly. Check for any leaks or abnormal behavior during operation. 8. Regular maintenance: Once the seal kits or O-rings are installed, it is important to regularly inspect and maintain them to ensure their longevity and optimal performance. Follow the manufacturer's recommended maintenance schedule and guidelines for best results. It is important to note that these guidelines are general in nature and may vary depending on the specific make and model of the concrete pump. Therefore, it is always recommended to consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q: What are the functions of concrete pump truck?

- Concrete large transport equipment, used in high-rise buildings, high-speed, overpass and other large concrete works of concrete transmission.

- Q: How long do concrete pump rubber hoses typically last?

- Concrete pump rubber hoses typically last around 1 to 5 years, depending on various factors such as usage, maintenance, and environmental conditions.

- Q: What are the signs of a faulty concrete pump control panel?

- There are several signs that can indicate a faulty concrete pump control panel. Firstly, if the control panel is not powering on or experiencing intermittent power loss, it could be a sign of a faulty electrical connection or a malfunctioning power supply. This can prevent the panel from functioning properly and controlling the concrete pump. Secondly, if the control panel is displaying error messages or error codes, it suggests that there may be an issue with the internal components or sensors. These errors can range from minor malfunctions to more serious problems that require immediate attention. Additionally, a faulty control panel may exhibit erratic behavior or unresponsive controls. For example, if the buttons or switches do not respond when pressed, or if they behave inconsistently, it could indicate a problem with the panel's circuitry or wiring. Moreover, unusual noises or vibrations coming from the control panel can be a sign of internal mechanical issues. These could include loose or damaged components, faulty relays, or malfunctioning motors. Lastly, if the concrete pump is not operating as expected, it could be due to a faulty control panel. Inadequate pressure, incorrect flow rates, or difficulty in starting or stopping the pump may all be indicators of a control panel malfunction. In any case, if you suspect that the control panel of a concrete pump is faulty, it is important to consult a professional technician or manufacturer for inspection, diagnosis, and repair.

- Q: How can a faulty outrigger affect the stability of the pump?

- A faulty outrigger can significantly affect the stability of a pump. The outrigger is an essential component that helps to support and balance the pump during operation. It acts as a stabilizer and prevents the pump from tipping over or vibrating excessively. If the outrigger is faulty, it may not provide the necessary support and stability required for the pump to function properly. This can lead to various stability issues. For example, the pump may become more prone to tipping over, especially if it is subjected to uneven surfaces or strong vibrations. This can be extremely dangerous, especially if the pump is dealing with hazardous or flammable materials. Additionally, a faulty outrigger can cause the pump to vibrate excessively. Vibrations can lead to increased wear and tear on the pump, resulting in premature failure of critical components. Excessive vibrations can also cause damage to the surrounding infrastructure or equipment, leading to costly repairs or even accidents. Furthermore, a faulty outrigger can affect the accuracy and efficiency of the pump's operation. If the pump is not properly stabilized, it may not be able to maintain a consistent flow rate or pressure, affecting its performance. This can result in inefficiencies, increased energy consumption, and even reduced productivity. In conclusion, a faulty outrigger can have a detrimental impact on the stability of a pump. It can increase the risk of accidents, cause excessive vibrations, and affect the pump's performance and efficiency. Regular maintenance and inspections are crucial to ensure that the outrigger and other support systems are functioning correctly to maintain the stability and reliability of the pump.

- Q: How can a faulty lubrication system affect the pump's performance?

- A faulty lubrication system can significantly affect the pump's performance in several ways. Firstly, a lubrication system is responsible for providing a thin film of lubricant between moving parts of the pump, reducing friction and wear. If the lubrication system is faulty or inadequate, it can result in increased friction between components, leading to excessive heat generation and accelerated wear and tear. This can ultimately reduce the efficiency and lifespan of the pump. Secondly, a faulty lubrication system can cause inadequate lubrication to critical components, such as bearings and seals. Insufficient lubrication can lead to increased friction, heat, and ultimately, premature failure of these components. This can result in increased downtime, costly repairs, and potential damage to other parts of the pump. Furthermore, a faulty lubrication system can also result in the contamination of the lubricant. Contaminants such as dirt, debris, or moisture can enter the system due to leaks or improper maintenance. These contaminants can cause abrasive damage to the pump's internal components, leading to reduced efficiency, increased wear, and potential failure. Lastly, a faulty lubrication system can also impact the pump's overall performance and energy consumption. Insufficient lubrication can increase the power requirements of the pump as it works harder to overcome friction and resistance. This can result in higher energy consumption and increased operating costs. In conclusion, a faulty lubrication system can severely impact the pump's performance by causing increased friction, accelerated wear and tear, premature failure of critical components, contamination of the lubricant, and increased energy consumption. Regular maintenance and proper lubrication are crucial to ensure the pump operates at its optimal level and to extend its lifespan.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R500 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords