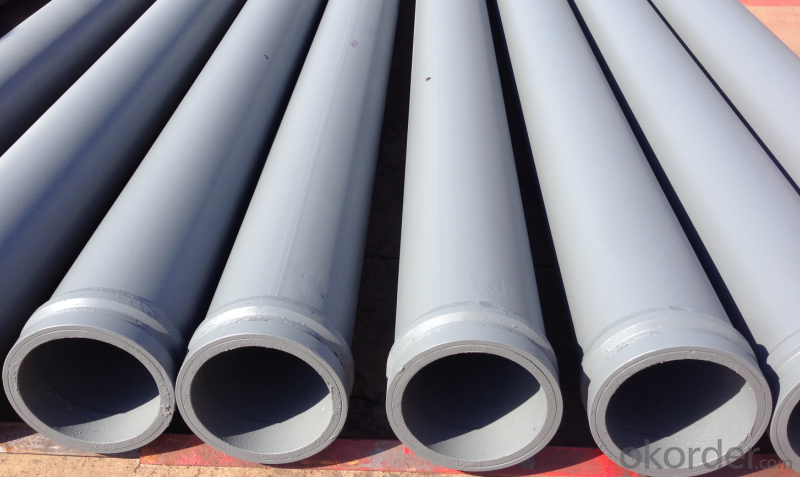

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 3m

Thickness: 4.1mm

Material: ST52

Weight: 40kg

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Concrete pump spare parts, such as wear plates or wear rings, have specific guidelines for their installation. These guidelines guarantee proper installation and optimal equipment performance. Here are some essential guidelines to consider: 1. Prior to installation, thoroughly examine the wear plates or wear rings for any damage or defects. Replace any damaged or worn-out parts to ensure efficient operation. 2. Ensure that the concrete pump and all related components are clean and clear of debris or contaminants. Doing so will prevent premature wear and prolong the lifespan of the wear plates or wear rings. 3. Before installation, apply a suitable lubricant to the wear plates or wear rings. This will minimize friction and extend the components' service life. 4. Proper alignment is crucial for the effective functioning of wear plates or wear rings. Make sure the plates or rings are correctly aligned and securely fixed in place. Misalignment can cause premature wear and equipment damage. 5. Use the recommended torque specifications to tighten the bolts or fasteners that secure the wear plates or wear rings. Improper tightening can result in equipment malfunction or damage. 6. Implement a regular maintenance schedule to inspect and replace worn-out wear plates or wear rings. Regular maintenance will help detect and address any issues before they lead to major breakdowns or costly repairs. It is important to consult the manufacturer's guidelines and adhere to their specific instructions for the installation of wear plates or wear rings in concrete pump spare parts. Following these guidelines will ensure the equipment's optimal performance and longevity.

- Q: What is the farthest pumping distance of concrete pump truck?

- Concrete pump, commonly known as to pump, or supporting pump, pumping height is determined by the power of the engine, 08 years in Guangzhou pearl, vanda heavy section pump made of C100 high strength concrete vertical height of 411 meters world record, the engine for the 572KW

- Q: What are the signs of a malfunctioning concrete pump outrigger?

- There are multiple indicators that point towards a malfunctioning concrete pump outrigger. 1. An uneven or unstable platform may suggest that the outrigger is not functioning properly. This can be observed when the pump is not level or when the platform exhibits excessive movement or shaking. 2. The presence of hydraulic fluid leaks in the outrigger's hydraulic system is a telltale sign of malfunction. If you notice puddles or stains on the ground caused by hydraulic fluid, it signifies a problem. 3. If the outrigger is slow to extend or retract, or if it does not respond to the controls, it indicates a malfunction. This can jeopardize the stability of the pump and should be taken seriously. 4. Unusual noises emanating from the outrigger, such as grinding, whining, or knocking sounds, can be indicative of mechanical issues or loose components. Ignoring these noises may lead to underlying problems that require attention. 5. It is crucial to visually inspect the outrigger for any visible damage, such as bent or cracked components, loose bolts, or missing parts. These physical signs of damage can impair the functionality and stability of the outrigger. Regular inspection and maintenance of the concrete pump outrigger are essential for ensuring safe and efficient operation. If any of these signs are present, it is advisable to cease using the pump and have it inspected and repaired by a qualified professional to prevent further damage or accidents.

- Q: What are the signs of a faulty concrete pump control box?

- Signs of a faulty concrete pump control box can vary depending on the specific issue. However, there are some common indicators to look out for: 1. Unresponsive controls: When the controls fail to function properly or become unresponsive, such as buttons not working or switches not engaging, it is a clear sign of a faulty control box. 2. Inaccurate readings: If the readings or measurements displayed on the control panel are inconsistent or incorrect, such as pressure readings or flow rates, it suggests a faulty control box. 3. Electrical problems: Faulty control boxes can cause electrical issues like flickering lights, sudden power surges or shortages, and blown fuses. These electrical problems can be dangerous and potentially cause further damage. 4. Strange noises: A faulty control box may produce unusual noises like buzzing, humming, or clicking sounds. These noises indicate loose connections, damaged components, or malfunctioning parts within the control box. 5. Pump malfunctions: The concrete pump itself can experience malfunctions due to a faulty control box. This can include inconsistent pumping, irregular flow, or sudden stops and starts, which can disrupt the concrete pouring process and lead to project delays. If you suspect a faulty concrete pump control box, it is crucial to address the issue promptly. It is recommended to seek assistance from a qualified technician or contact the manufacturer for help in diagnosing and repairing the control box.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Yes, there are specific guidelines for the storage and handling of concrete pump spare parts during transportation. These guidelines are in place to ensure the safe and efficient transportation of the spare parts, as well as to minimize the risk of damage or loss. Firstly, it is important to ensure that the spare parts are properly packaged and protected. This includes using appropriate packaging materials such as cardboard boxes, bubble wrap, or foam padding to prevent any physical damage during transit. The spare parts should be securely packed to prevent any movement or shifting during transportation. Additionally, it is recommended to label the packages clearly with the contents and any specific handling instructions. This will help the transport personnel to handle the spare parts correctly and avoid any mishandling or confusion. Furthermore, it is essential to choose a reliable and experienced transportation service provider who has expertise in handling delicate and sensitive items like concrete pump spare parts. They should have proper equipment, such as pallet jacks or forklifts, to handle and move the spare parts safely. During transportation, it is important to ensure that the spare parts are loaded and secured properly in the transport vehicle. This may involve using straps, ropes, or other securing devices to prevent any movement or shifting of the packages. In terms of temperature control, it is vital to consider the specific requirements of the spare parts. Some parts may be sensitive to extreme temperatures and require special handling or climate-controlled transportation. It is important to consult with the manufacturer or supplier of the spare parts to determine any specific temperature or climate requirements. Overall, following these guidelines will help ensure the safe and secure transportation of concrete pump spare parts, reducing the risk of damage or loss and ensuring their readiness for use when they reach their destination.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Certainly, before installation, it is possible to examine concrete pump spare parts to ensure their dimensional accuracy. It is crucial to verify that the spare parts meet the necessary specifications and dimensions for proper functioning and compatibility with the concrete pump system. One can perform this inspection using a range of techniques, including visual examination, precise instrument measurements, and comparing dimensions to the manufacturer's specifications. This procedure aids in detecting any disparities or deviations in the spare parts' dimensions, enabling adjustments or replacement if needed. By inspecting spare parts for dimensional accuracy prior to installation, one can guarantee the seamless operation and durability of the concrete pump system.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- To determine if the concrete pump cylinder needs replacement, you can perform a few inspections and tests. 1. Visual inspection: Look for any visible signs of wear and tear on the cylinder, such as cracks, dents, or corrosion. Additionally, check for any leaks or excessive hydraulic fluid around the cylinder. 2. Performance evaluation: Pay attention to the pump's performance during operation. If you notice a decrease in pumping efficiency, irregular flow, or decreased pressure, it could indicate a problem with the cylinder. 3. Pressure testing: Conduct a pressure test to determine if the cylinder can handle the required pressure. This can be done by isolating the cylinder and pressurizing it to a level higher than what it typically experiences during operation. If the cylinder fails to maintain pressure or shows signs of leakage, it may be time for a replacement. 4. Cylinder stroke measurement: Measure the stroke length of the cylinder during operation. Uneven stroke lengths can indicate internal damage to the cylinder and may require replacement. 5. Consultation with experts: If you are unsure about the condition of the cylinder, it is advisable to consult with professionals or experts in the field. They can provide you with a more accurate assessment and recommend the appropriate course of action, which may include cylinder replacement. Keep in mind that regular maintenance and inspections are crucial for the longevity and efficient operation of the concrete pump. It is always better to address potential issues early on to avoid further damage or accidents.

- Q: What are the precautions for gas washing of concrete pump?

- During gas cleaning, the personnel shall not be close to the outlet of the discharge pipe, the pipe is turned sharply (if 90 bends) and the compressed air pipe is connected

- Q: What are the advantages of using tungsten carbide components in concrete pump spare parts?

- There are several advantages of using tungsten carbide components in concrete pump spare parts. Firstly, tungsten carbide is an extremely hard and durable material, which ensures longer lifespan and increased wear resistance of the components. This means reduced maintenance and replacement costs in the long run. Additionally, tungsten carbide has excellent corrosion resistance, making it suitable for use in harsh and corrosive environments commonly found in concrete pumping applications. Furthermore, tungsten carbide components offer superior strength and toughness, enabling them to withstand high-pressure and heavy-duty operations without compromising performance. Overall, the use of tungsten carbide in concrete pump spare parts leads to improved efficiency, reliability, and cost-effectiveness in concrete pumping operations.

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- Some indications of an inaccurate concrete pump pressure gauge may include inconsistent readings, sudden drops or spikes in pressure, or when the gauge fails to return to zero when the pump is turned off.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords