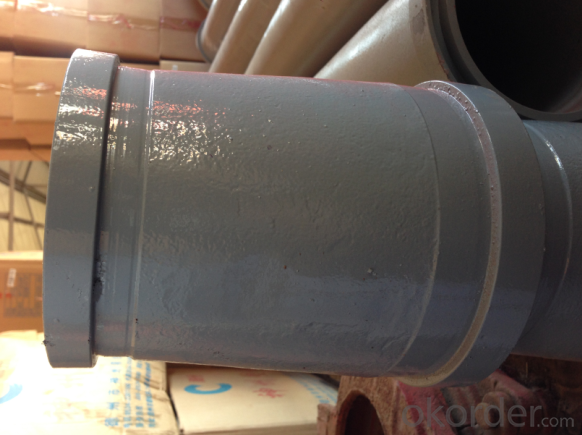

Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery bend connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

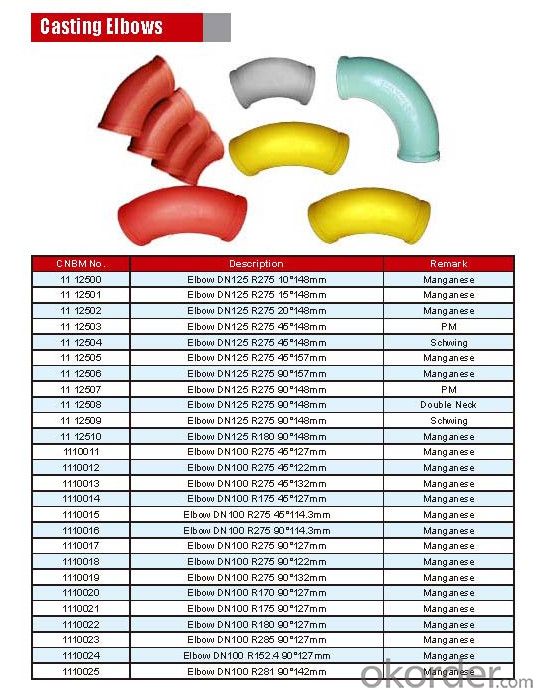

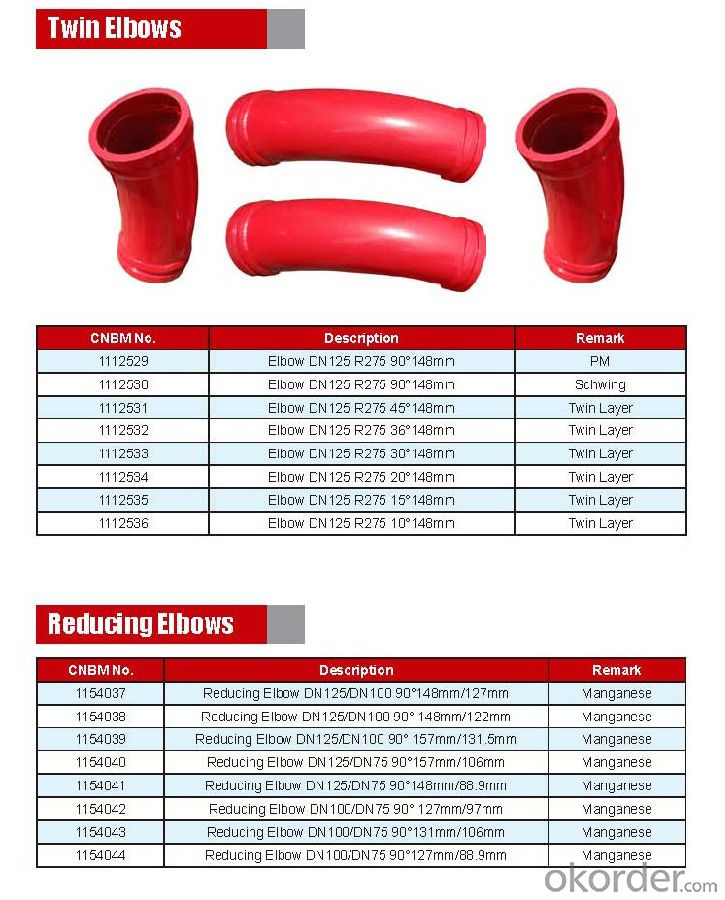

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. Service life:6000-15000 CBM Concrete.

3. We can supply OEM service and can also produce according to your requirements.

4. Normal and female/male flanges are both available to suit for normal or high pressure concrete pumping

5. Possess quality certification of ISO 9001:2000. Can pass CE test.

6. Fitting to PUTZMEISTER, SCHWING Sany, Zoomlion concrete pumps

Product Specifications:

Technical: Casting

Radius: 1000mm

Degree: 90

Material: Mn13-4

Characteristics: According to our technology, the casting bends also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- Hopper agitator shaft seals in a concrete pump should be replaced as per the manufacturer's recommendations. However, as a general guideline, it is advisable to inspect and replace them annually or whenever signs of wear, leakage, or reduced performance are observed. Regular maintenance and proper lubrication can also help prolong the lifespan of these seals.

- Q: What are the different types of concrete pump hopper agitator shaft seals?

- There are various types of concrete pump hopper agitator shaft seals, including packing seals, mechanical seals, and lip seals.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Concrete pump pressure gauges should be inspected and replaced on a regular basis, ideally every six months or as recommended by the manufacturer. Regular inspections help ensure accurate pressure readings and prevent potential accidents or malfunctions due to faulty gauges.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. Regular cleaning of the spare parts is necessary to remove any dirt, debris, or concrete buildup that may affect their performance. This can be done using water, mild detergent, and a brush to scrub the parts gently. Additionally, lubrication of moving parts and regular inspection for wear and tear is crucial to ensure optimal functioning and longevity of the spare parts.

- Q: What are the types, classifications and specifications of concrete pump?

- According to the ability of mixing materials, select the range of output; according to the aggregate of pumping concrete, select the form of the distribution valve

- Q: How do concrete pump spare parts help in the pumping process?

- The smooth and efficient operation of a concrete pump relies heavily on spare parts. These parts are crucial for enhancing performance, extending the pump's lifespan, and ultimately saving costs. The use of concrete pump spare parts offers several advantages, one of which is improved pumping efficiency. These parts are meticulously manufactured to ensure the optimal flow of concrete through the pump. For example, the wear plate, wear ring, and S valve all play a crucial role in reducing friction and enhancing pumping performance. By minimizing friction and maintaining a consistent flow, these spare parts prevent blockages and allow for the smooth and efficient pumping of concrete. In addition, concrete pump spare parts are vital for minimizing downtime and reducing maintenance costs. Since the pump operates continuously, wear and tear are inevitable. However, replacing worn-out parts with high-quality spare parts on a regular basis can significantly prolong the pump's lifespan and decrease the need for frequent repairs. Investing in durable and reliable spare parts helps operators avoid unexpected breakdowns and costly repairs, ensuring uninterrupted and efficient pumping operations. Furthermore, concrete pump spare parts contribute to the safety of the pumping process. Components such as the safety valve, hopper grate, and control system all play critical roles in preventing accidents and ensuring the well-being of operators. These spare parts are designed to facilitate the safe and controlled pumping of concrete, reducing the risk of equipment failure and potential hazards. In conclusion, concrete pump spare parts are indispensable in the pumping process as they improve efficiency, minimize downtime and maintenance costs, and enhance safety. By investing in high-quality spare parts, operators can optimize the pump's performance, increase productivity, and achieve long-term cost savings.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Indeed, procuring spare parts for concrete pumps equipped with various valve systems, such as S-valve or gate valve, is entirely feasible. Manufacturers and suppliers of concrete pumps generally offer an extensive selection of spare parts, which encompass valves. These spare parts can be procured either directly from the manufacturer or via authorized distributors. To ensure compatibility, it is vital to furnish precise information regarding the concrete pump model, valve type, and any other pertinent details when placing an order for spare parts. Moreover, there exist specialized firms that exclusively concentrate on providing spare parts for concrete pumps, irrespective of the valve system employed. These entities often possess a comprehensive inventory of spare parts and can offer assistance in identifying and sourcing the necessary components for your specific concrete pump.

- Q: How can one store and handle concrete pump spare parts to maintain their quality?

- To maintain the quality of concrete pump spare parts, it is crucial to store and handle them properly. Firstly, these spare parts should be stored in a clean and dry environment, away from moisture and direct sunlight. They should also be protected from dust and debris by using suitable covers or packaging. Additionally, it is important to handle them with care, avoiding any rough or improper handling that could cause damage. Regular inspection and maintenance of the spare parts should also be conducted to identify any signs of wear or corrosion, ensuring they are in optimal condition when needed for use.

- Q: How is the piping of the concrete pipe designed?

- In the same line, should transfer the same diameter concrete pipe; at the same time, using the new 1 pipe section, should be the new arrangement of the tube in the pump delivery pressure is larger; pipes should be arranged vertically

- Q: How often should hopper vibrators be inspected or replaced in a concrete pump?

- Hopper vibrators in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure they are functioning properly. If any signs of wear, damage, or decreased performance are observed, it is recommended to replace them promptly to avoid any disruptions or issues during concrete pumping operations.

Send your message to us

Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords