High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Cold Drawn Aluminum Alloy Plate Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Cold Drawn Aluminum Alloy Plate :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

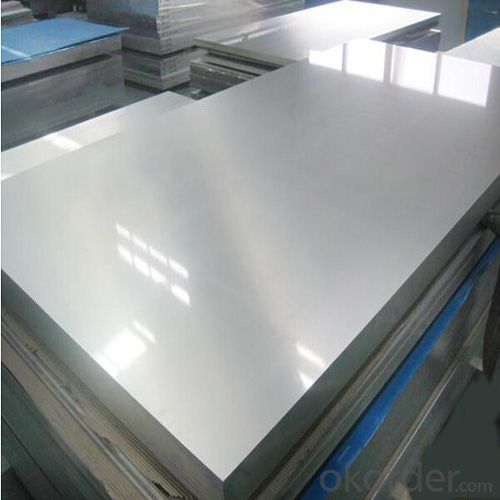

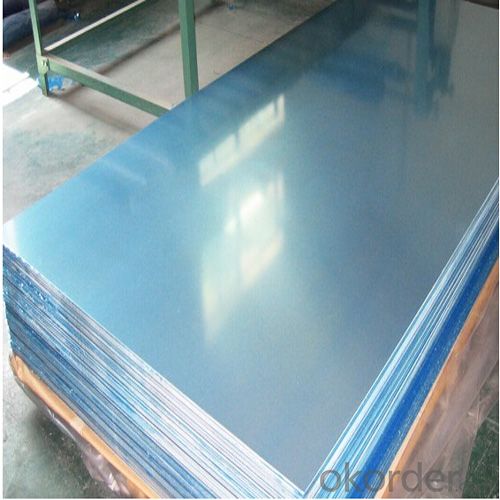

3. Cold Drawn Aluminum Alloy Plate Images:

4. Cold Drawn Aluminum Alloy Plate Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: Can aluminum sheets be used for heat sinks?

- Yes, aluminum sheets can be used for heat sinks. Aluminum has excellent thermal conductivity properties, making it an ideal material for transferring heat away from electronic components. Aluminum sheets can be formed into various shapes and sizes to maximize heat dissipation. They are commonly used in applications such as computer processors, LED lights, and power electronics, where efficient heat dissipation is crucial for maintaining optimal performance and preventing overheating. Additionally, aluminum sheets are lightweight and cost-effective, making them a popular choice for heat sink applications.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: Is aluminum sheet fire-resistant?

- Although aluminum sheet is not inherently fire-resistant, it exhibits specific properties that grant it superior fire resistance compared to alternative materials. One such property is its high melting point, enabling it to endure elevated temperatures without melting or igniting. Another advantage is its low thermal conductivity, which limits heat transfer and impedes the spread of fire across the sheet. Nevertheless, it is crucial to acknowledge that aluminum can still be affected by fire. Exposure to extreme heat may cause it to weaken and compromise its structural integrity. Additionally, certain chemicals or intense flames can render aluminum more susceptible to burning. To enhance the fire resistance of aluminum sheet, one can apply fire-retardant materials or treat it with fire-resistant coatings. These supplementary measures serve to further minimize the risk of fire and enhance the overall fire performance of the sheet. In conclusion, while aluminum sheet is not entirely fire-resistant, it possesses certain attributes that contribute to its heightened resistance compared to other materials. Nonetheless, it is imperative to exercise appropriate precautions and apply additional fire-resistant treatments when necessary to ensure optimal safety.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Aluminum sheets generally have good chemical resistance due to the formation of a protective oxide layer on their surface. This oxide layer helps prevent corrosion and protects the aluminum from many common chemicals. However, aluminum can react with certain aggressive acids and alkalis, so it is important to consider the specific chemical environment when assessing its chemical resistance.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. Aluminum is a widely used material in the pharmaceutical industry due to its various beneficial properties. Firstly, aluminum sheets are lightweight and have excellent corrosion resistance. This makes them ideal for packaging pharmaceutical products as they can protect the contents from external factors such as moisture, light, and oxygen, which could potentially degrade the quality of the medication. Additionally, aluminum sheets can be easily formed into different shapes and sizes, allowing for customization in packaging design. They are also available in various thicknesses, providing options for different types of pharmaceutical products, from tablets and capsules to liquid medications. Furthermore, aluminum sheets have a high barrier property, effectively preventing the transfer of odors, flavors, and contaminants. This ensures the integrity and safety of the medication throughout its shelf life. Moreover, aluminum is a non-toxic material, which means it does not react with drugs or alter their composition. This makes it a suitable choice for pharmaceutical applications, where maintaining the purity and stability of the medication is crucial. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications due to their lightweight, corrosion resistance, barrier properties, and non-toxic nature. They provide efficient protection and preservation of pharmaceutical products, ensuring their quality and safety.

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Aluminum sheets prove to be a fitting option for chemical filtration applications. Renowned for its outstanding corrosion resistance and durability, aluminum emerges as a trustworthy selection for chemical filtration systems. It diligently sieves out impurities and contaminants across diverse chemical procedures, encompassing the separation of solids from liquids and the elimination of hazardous substances. Furthermore, aluminum sheets boast resilience against elevated temperatures and pressures, rendering them well-suited for an extensive array of chemical filtration applications.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

Send your message to us

High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords