Colored Anodized Aluminum Cold Rolled Sheets with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

hot rolled and cold drawn aluminum plate are both widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

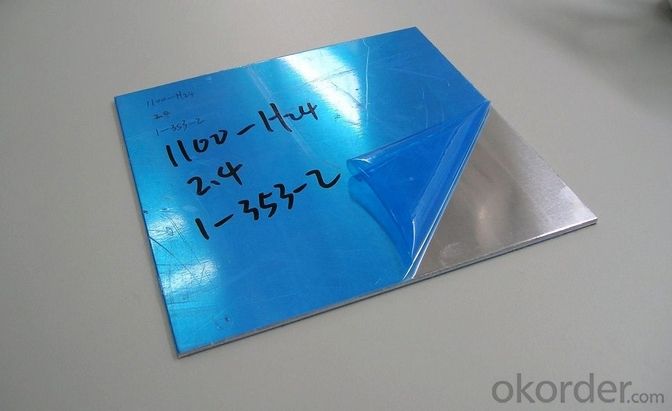

3. Image

4. Product detailed sizes:

1000mm*2000mm,1250mm*2500mm, 1219mm*2438mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 610mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

---Normally it is around 6 tons/each size.

Where is your client from?

---Normally it is from Turkey,Fiji, UAE, Saudi Arabia, Bangladesh, Sri Lanka, etc.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum composite panel, aluminum sandwich panel,etc.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Indeed, aluminum sheets prove to be a suitable material for the production of electrical enclosures. Within the manufacturing industry, aluminum is widely utilized due to its versatility and numerous advantages. To begin with, aluminum possesses a unique combination of lightweight properties and strength, making it an ideal choice for constructing enclosures that require durability without the burden of excessive weight. Its strength-to-weight ratio surpasses that of many other metals, allowing for the creation of sturdy enclosures without unnecessary bulkiness. Moreover, aluminum exhibits exceptional resistance to corrosion, a crucial attribute for electrical enclosures that may encounter various environmental conditions, such as moisture, humidity, or corrosive elements. The natural oxide layer present on aluminum acts as a protective barrier, ensuring the enclosures' longevity and reliability. Additionally, aluminum possesses excellent electrical conductivity, a vital characteristic for electrical enclosures. This property facilitates efficient dissipation of heat generated by electrical components, effectively preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is highly machinable and can be easily molded into different shapes and sizes. This inherent flexibility enables manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Finally, when considering cost-effectiveness, aluminum proves to be a more economical choice compared to other metals such as stainless steel or copper. It strikes a balance between affordability and performance, making it an attractive option for the manufacturing of electrical enclosures. In conclusion, the lightweight nature, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness of aluminum sheets make them a highly suitable material for the production of electrical enclosures.

- Q: What are the typical thickness options for aluminum sheets?

- The typical thickness options for aluminum sheets range from 0.006 inches to 0.25 inches, depending on the specific application and requirements.

- Q: What is the price range of aluminum sheets?

- The cost of aluminum sheets can fluctuate due to multiple elements, including the sheet's dimensions, thickness, and quality, as well as the supplier and market circumstances. Typically, the price of aluminum sheets can vary between approximately $0.50 and $5 per square foot. Thinner sheets or lower-quality aluminum tend to occupy the lower end of this price spectrum, while thicker sheets or higher-quality aluminum tend to fall on the higher end. It is advisable to compare prices among various suppliers to secure the most advantageous offer.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that creates a protective layer on the surface of aluminum, enhancing its corrosion resistance, durability, and aesthetic appearance. It is commonly used in the medical industry to improve the performance and longevity of equipment, as well as to maintain cleanliness and sterility. The specific alloy of aluminum used, such as 101, does not typically impact the anodizing process, as anodizing can be applied to various grades of aluminum. However, it is important to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most suitable anodizing process and specifications.

- Q: What are the different types of alloys used for aluminum sheets?

- Aluminum sheets can be made from different types of alloys, each with its own unique properties and uses. Here are some of the most commonly used ones: - The 1100 alloy is pure aluminum and has excellent resistance to corrosion and good formability. It is often utilized for general sheet metal work like roofing and siding. - The 3003 alloy is similar to 1100 but contains added manganese, which makes it slightly stronger. It is commonly employed for applications that require moderate strength and good resistance to corrosion, such as packaging and automotive parts. - The 5052 alloy is renowned for its exceptional corrosion resistance, particularly in marine environments. It is also highly formable and weldable, making it suitable for various applications like fuel tanks, marine components, and architectural panels. - The 6061 alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and resistance to corrosion. It is commonly found in structural applications like aircraft parts, bicycle frames, and automotive components. - The 7075 alloy is a high-strength alloy frequently utilized in aerospace and military applications. It exhibits excellent resistance to fatigue and is easily machinable. It is typically employed for aircraft structures, missile parts, and high-stress components. These examples illustrate the variety of aluminum alloys available for sheet production. The choice of a specific alloy depends on desired properties, such as strength, resistance to corrosion, formability, and cost, as well as the intended application.

- Q: Are aluminum sheets suitable for reflective signage?

- Yes, aluminum sheets are suitable for reflective signage. Aluminum is a versatile material that is commonly used for reflective signs due to its durability, lightweight nature, and ability to reflect light. It has a high reflectivity index, making it ideal for applications where visibility is crucial, such as road signs, traffic signs, and safety signs. Aluminum sheets can be coated with reflective films or paints to enhance their reflective properties, ensuring maximum visibility even in low light conditions. Additionally, aluminum is resistant to weathering, corrosion, and fading, making it a long-lasting and cost-effective choice for reflective signage.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: Can aluminum sheets be used for reflectors?

- Yes, aluminum sheets can be used for reflectors.

- Q: What are the different types of alloys used in aluminum sheet?

- Aluminum sheet incorporates a variety of alloys with distinct characteristics. Some of the most frequently employed alloys include: 1. The 3003 alloy is renowned for its exceptional corrosion resistance and finds utility in situations where moisture exposure is a concern. It is also highly malleable and can be easily welded, making it a popular choice for various structural components. 2. The 5052 alloy boasts remarkable corrosion resistance and excellent formability. It is commonly used in marine and automotive applications, as well as architectural elements. 3. The 6061 alloy provides unparalleled strength and is widely utilized in applications demanding high structural integrity. It is commonly found in the aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. The 7075 alloy is celebrated for its exceptional strength-to-weight ratio and is extensively employed in aerospace and defense applications. Furthermore, it is utilized in the manufacture of bicycle frames, rock climbing equipment, and other high-performance applications. 5. The 2024 alloy is renowned for its strength and outstanding fatigue resistance. It is frequently utilized in aerospace applications, as well as in the production of structural components and fasteners. These aforementioned examples merely scratch the surface of the multitude of alloys used in aluminum sheet. Each alloy possesses its own unique properties and advantages, rendering it suitable for specific industries and applications.

- Q: what kind of abradant should be used in the deburring of aluminum sheets? How to grind?

- you can use deburring brush,grinding fluid,abrasive powder and other consumables.

Send your message to us

Colored Anodized Aluminum Cold Rolled Sheets with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords