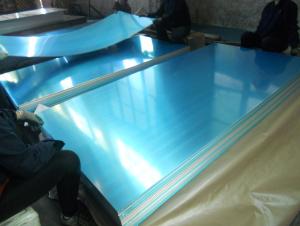

Prepainted Gold Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors. Aluminum is a highly conductive material and has excellent electrical conductivity. It is commonly used in various electrical applications, including connectors. Aluminum connectors are lightweight, durable, and cost-effective compared to other materials such as copper. However, it is important to consider certain factors such as the type and size of the connection, the amount of current to be carried, and the environment in which the connectors will be used. Additionally, proper insulation and protection measures should be taken to prevent corrosion, as aluminum can be susceptible to oxidation. Overall, aluminum sheets can be a suitable choice for electrical connectors, but careful consideration of specific requirements and conditions is necessary.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- You don't mention just what this project is, but 'regular' screws in the aluminum will not 'rust' - but they may cause galvanic action (a white powdery aluminum oxide may form over time.) Most hardware stores carry aluminum screws, why not just buy and use them if you are concerned? They are usually used for aluminum replacement windows and may be painted white. You can use sandpaper to remove the paint if you want the silver to show.

- Q: How could two pieces of aluminium flakes be welded together?

- You can use argon arc welding, connect the positive pole with alternating current,aluminum wire as the welding wire.

- Q: Remember the notorious Chevy Vega of the 1970's? As I recall,one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs arealso equipped with aluminum engines to reduce curb weightand improve fuel efficiency. Will they be prone to the sameproblems that the Vega had down the road? Are there othermanufacturers that have used aluminum engines with successrecently?

- Aluminum is a WEAK metal....it is SOFT compared to iron or CGI. It sucks in engines.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- In the presence or air, the aluminum oxidizes so fast that making a bond becomes extremely difficult. The shielding gas prevents oxidation by excluding oxygen. The gas doesn't enter into the process, it just inhibits oxidation.

- Q: What is the maximum temperature that the aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on the specific grade of aluminum being used. Generally, most aluminum alloys can withstand temperatures up to 600-650 degrees Fahrenheit (315-343 degrees Celsius) without losing their structural integrity. However, it is important to note that prolonged exposure to high temperatures can cause aluminum to weaken and eventually deform or melt. Therefore, it is recommended to consult the manufacturer's specifications or testing data for the specific aluminum grade being used to determine its maximum temperature tolerance.

- Q: what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

Send your message to us

Prepainted Gold Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords