Climbing Bracket CB240 & CB210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

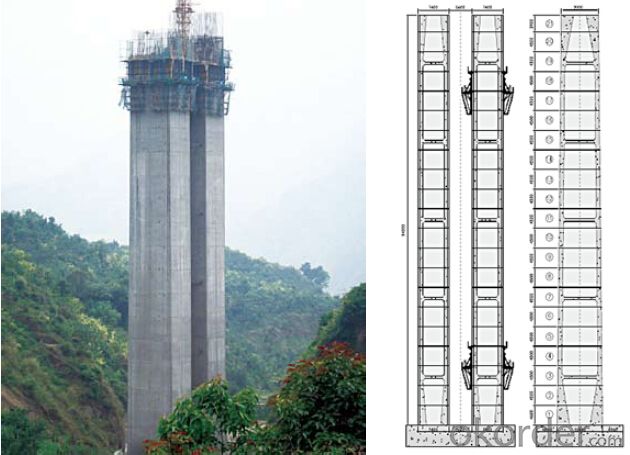

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: How does steel formwork affect the overall project timeline?

- Steel formwork can have a significant impact on the overall project timeline. One of the main advantages of using steel formwork is its durability and reusability. Unlike traditional timber formwork, steel formwork can withstand multiple uses and can be easily assembled and dismantled. This results in faster construction times as the formwork can be quickly set up and reused on different parts of the project. Additionally, steel formwork provides a higher level of precision and accuracy, ensuring that the concrete structures are built to the exact specifications. This eliminates the need for any rework or adjustments, saving both time and resources. The use of steel formwork also allows for faster concrete curing times, as the steel panels provide better insulation and can retain heat, accelerating the curing process. Moreover, steel formwork is known for its strength and stability, which reduces the risk of accidents and delays during the construction process. Its robustness allows for the pouring of larger concrete sections at once, increasing productivity and minimizing the number of pour cycles required. However, it's important to note that while steel formwork can expedite the construction process, it may require additional planning and coordination. The design and fabrication of steel formwork should be done well in advance to ensure it aligns with the project timeline. Any modifications or adjustments to the formwork design must also be carefully managed to avoid disruptions to the overall schedule. In conclusion, steel formwork can have a positive impact on the overall project timeline by providing durability, reusability, precision, faster curing times, and increased productivity. However, it is crucial to carefully plan and coordinate the use of steel formwork to maximize its benefits and minimize any potential delays.

- Q: How does steel formwork contribute to the sustainability of a project?

- There are several ways in which steel formwork supports the sustainability of a project. Firstly, steel is an incredibly durable material that can withstand the challenges of construction and repeated use. This means that steel formwork can be reused multiple times, reducing the need for new formwork to be manufactured for each project. By minimizing the demand for new materials, steel formwork contributes to the conservation of natural resources and the reduction of the environmental impact associated with extracting, producing, and transporting construction materials. Furthermore, steel formwork offers exceptional dimensional stability, ensuring precision and accuracy during construction. This reduces the chances of errors and rework, leading to a more efficient use of resources such as time, labor, and materials. Additionally, the use of steel formwork results in smooth and high-quality finishes, minimizing the need for additional surface treatments or finishes that can be resource-intensive and contribute to waste generation. Moreover, steel formwork can be easily dismantled and recycled at the end of its lifespan. The steel can be melted down and repurposed for other construction projects, diverting waste from landfills and reducing the demand for newly produced steel. This approach aligns with the principles of a circular economy and helps to decrease the carbon footprint of the construction industry. Lastly, steel formwork enhances safety on construction sites. Its strength and stability minimize the risk of accidents and structural failures, providing protection to workers and the surrounding environment. By promoting a safe working environment, steel formwork contributes to the overall sustainability of a project by preventing injuries, reducing medical costs, and minimizing the negative social and economic impacts associated with accidents. In conclusion, steel formwork supports project sustainability through its durability, reusability, dimensional stability, recyclability, and safety advantages. By reducing the need for new materials, minimizing waste generation, and enhancing construction efficiency, steel formwork helps to conserve resources, mitigate environmental impacts, and foster a more sustainable construction industry.

- Q: How long does steel formwork last?

- Various factors, including the quality of the steel used, the frequency and type of usage, and the maintenance practices employed, can affect the lifespan of steel formwork. Typically, steel formwork is renowned for its durability and longevity, and with proper maintenance, it can endure for numerous years or even decades. When steel formwork is consistently maintained and handled correctly, it can endure multiple uses and continue to function effectively. However, it is important to acknowledge that over time, steel formwork may experience wear and tear due to constant exposure to concrete, which can result in surface corrosion or deterioration. To address this, protective coatings can be applied or the formwork can be cleaned after each use. Moreover, external factors like environmental conditions and the type of concrete used can also impact the lifespan of steel formwork. Exposure to harsh weather conditions or chemicals can expedite the corrosion process, potentially reducing the formwork's lifespan. To ensure the durability of steel formwork, it is crucial to invest in high-quality steel with proper anti-corrosion properties, conduct regular inspections, and perform necessary maintenance and repairs as required. By adhering to these practices, steel formwork can endure for a significant period, making it a cost-effective and dependable choice for construction projects.

- Q: How does steel formwork affect the overall construction site noise pollution?

- Steel formwork can have a significant impact on reducing overall construction site noise pollution. Compared to traditional wooden formwork, steel formwork offers better acoustic insulation properties. The rigid and dense nature of steel materials helps to absorb and dampen sound waves, minimizing the propagation of noise. This reduced noise propagation can be especially beneficial in densely populated areas or construction sites located near residential or commercial areas. Furthermore, steel formwork is often prefabricated, meaning it is manufactured off-site and then assembled on-site. This process helps to reduce construction noise as it requires fewer on-site activities and reduces the need for cutting, drilling, and hammering, which are major sources of noise pollution. Additionally, the use of steel formwork can lead to faster construction times, resulting in shorter exposure to noise for neighboring communities. Moreover, steel formwork is more durable and long-lasting than wooden formwork, which means it can be reused multiple times. This reusability reduces the need for frequent formwork installation and dismantling, further decreasing noise pollution generated during the construction process. Overall, the use of steel formwork in construction can greatly contribute to minimizing noise pollution at the construction site. Its superior acoustic insulation properties, reduced on-site activities, and longer lifespan all work together to create a quieter and more environmentally friendly construction environment.

- Q: How is steel formwork assembled and disassembled?

- Steel formwork is assembled and disassembled in a systematic and sequential manner to ensure efficient construction processes. The assembly process generally begins with the foundation preparation, where the steel formwork components are laid out according to the desired shape and dimensions of the structure. The first step in assembling steel formwork involves connecting the vertical and horizontal components using various connecting devices such as pins, bolts, or clips. These components, which include panels, walers, and soldiers, are interconnected to form a rigid framework that provides the necessary support and shape for the concrete structure. Once the initial framework is assembled, the next step involves the placement of form ties or clamps, which are used to hold the formwork panels firmly in place. These ties or clamps are inserted through holes in the panels and then secured tightly on the opposite side to prevent any movement during the pouring and curing of the concrete. After the concrete is poured and cured, the disassembly process begins. This process is carried out in reverse order, starting with the removal of the form ties or clamps. Once these are removed, the formwork panels can be easily detached from the framework, allowing for the removal of the soldiers and walers. The disassembly of steel formwork also involves carefully dismantling the vertical and horizontal components, ensuring that no damage is caused to the framework or the panels. This is done by removing the connecting devices, such as pins, bolts, or clips, and then systematically disassembling the various components. It is important to note that the assembly and disassembly of steel formwork should be carried out by experienced and trained professionals to ensure safety and avoid any potential accidents or structural failures. Following proper procedures and guidelines is crucial to guarantee the successful completion of a construction project using steel formwork.

- Q: Are there any specific safety measures to be followed during steel formwork installation?

- During steel formwork installation, it is important to adhere to specific safety measures. Here are some of the most crucial ones: 1. Personal Protective Equipment (PPE) must be worn by all workers involved. This includes safety helmets, gloves, safety glasses, and steel-toed boots. These protective gears are essential for safeguarding against potential head, hand, eye, and foot injuries. 2. Workers should undergo proper training and be competent in steel formwork installation. They should have a thorough understanding of the equipment used, correct installation techniques, and potential hazards associated with the work. 3. Before commencing the installation process, a thorough inspection of all formwork equipment, such as steel frames, braces, and connectors, should be conducted to identify any damage or defects. Damaged or defective equipment should be immediately replaced. 4. To ensure safety, a secure and stable platform should be established for workers to carry out the installation. This may involve the use of scaffolding or other supporting structures. The platform should be erected properly and undergo stability inspection prior to work commencement. 5. Fall protection measures should be implemented to prevent workers from falling during the installation process. This may include the use of guardrails, safety harnesses, and safety nets. Workers should receive adequate training on the proper use of fall protection equipment and procedures. 6. When moving and positioning steel formwork, proper lifting and handling techniques should be employed. Workers should avoid overexertion and utilize mechanical aids, such as cranes or hoists, when necessary. Additionally, workers should be mindful of their posture and avoid awkward or strenuous lifting positions. 7. Effective communication and coordination among workers are vital during steel formwork installation. Clear instructions, proper signaling, and a designated person in charge of coordinating the work are essential to prevent accidents and ensure a smooth and safe installation process. By adhering to these safety measures, the risk of accidents and injuries during steel formwork installation can be significantly reduced, thereby creating a safer working environment for all individuals involved.

- Q: Can steel formwork be easily customized?

- Yes, steel formwork can be easily customized. Steel is a highly versatile material that can be molded and shaped into various configurations according to the specific requirements of a construction project. Steel formwork can be easily cut, bent, welded, and fabricated to create customized formwork systems that fit the unique shape and dimensions of a structure. This flexibility allows for the construction of complex geometries, curves, and patterns, making it suitable for various architectural designs. Additionally, steel formwork can be reused multiple times, further enhancing its customization capabilities and cost-effectiveness.

- Q: How does steel formwork handle different concrete slump flow measurements?

- Steel formwork is highly durable and rigid, making it suitable for handling various concrete slump flow measurements. Its robust structure provides excellent support and stability, ensuring that the concrete maintains its desired shape and form during the pouring and curing process. Additionally, steel formwork can be easily adjusted and modified to accommodate different slump flow measurements, allowing for precise and efficient construction.

- Q: What are the considerations when designing a steel formwork system?

- When designing a steel formwork system, there are various important factors that must be taken into account. These factors encompass: 1. Ensuring Structural Integrity: It is crucial to design the steel formwork system in a manner that guarantees sufficient structural integrity to withstand the loads and pressures exerted by the wet concrete during pouring and curing. This entails preventing any deformation or failure, as well as considering the appropriate thickness and reinforcement of the steel components. 2. Prioritizing Durability: The formwork system should be designed with durability and longevity in mind, as it will undergo multiple uses and may need to be reused for different construction projects. The steel used should be resistant to corrosion, and all components should be adequately coated or protected to prevent rust and deterioration over time. 3. Emphasizing Flexibility and Adaptability: The design of the steel formwork system should allow for flexibility and adaptability to meet different construction requirements. This includes considering the ability to easily adjust the formwork to accommodate various shapes, sizes, and configurations of concrete structures. The system should also enable straightforward assembly, disassembly, and reconfiguration to facilitate efficient and cost-effective use. 4. Ensuring Safety: Safety is paramount when designing a steel formwork system. The design should incorporate appropriate safety features, such as guardrails, handrails, and non-slip surfaces, to prevent accidents and ensure the well-being of workers. Additionally, the formwork system should be designed to minimize the risk of concrete blowouts or collapses, and measures should be implemented to ensure the stability and rigidity of the system. 5. Considering Cost-effectiveness: The overall cost-effectiveness of the steel formwork system should be evaluated during the design phase. This involves assessing the initial cost of materials and fabrication, as well as the potential for reuse and ease of maintenance. The design should strive to minimize waste, maximize efficiency, and ultimately provide a cost-effective solution for the construction project. In conclusion, when designing a steel formwork system, it is essential to consider factors such as structural integrity, durability, flexibility and adaptability, safety, and cost-effectiveness. By addressing these considerations, a well-designed steel formwork system can contribute to the successful and efficient completion of a construction project.

- Q: Can steel formwork be used for concrete culverts?

- Yes, steel formwork can be used for concrete culverts. Steel formwork is a durable and strong material that can withstand the pressure and weight of the concrete. It provides a smooth surface finish and allows for easy installation and removal. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for constructing concrete culverts.

Send your message to us

Climbing Bracket CB240 & CB210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches