Climbing-Bracket CB240 and CB210 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

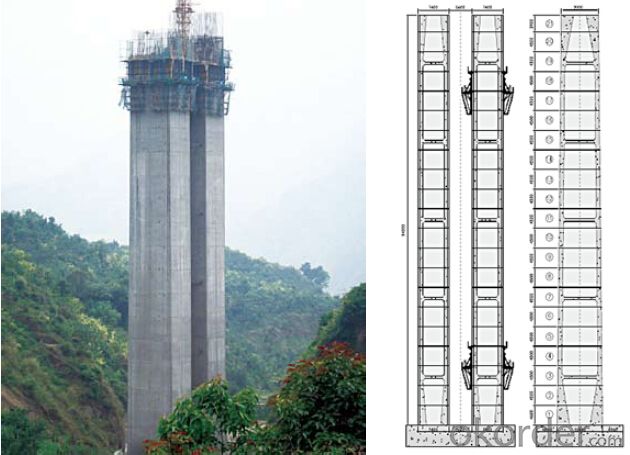

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: How does steel formwork affect the overall project cost estimation?

- The overall project cost estimation can be significantly influenced by the use of steel formwork. Although steel formwork may have a higher initial cost when compared to materials like timber or plywood, it offers several advantages that can lead to long-term cost savings. To begin with, steel formwork is extremely durable and can be used multiple times. Unlike timber or plywood formwork that may require replacement after a few uses, steel formwork can withstand numerous cycles, reducing the need for frequent replacements. This not only saves on material costs but also reduces the labor and time required for formwork installation and removal. Moreover, steel formwork provides superior quality finishes, resulting in a decreased need for surface treatments or plastering. This saves both material and labor costs associated with finishing work. Furthermore, steel formwork offers greater precision and dimensional accuracy, reducing the need for rework or adjustments during construction. This helps minimize material wastage and saves time and labor costs. In addition, steel formwork is highly resistant to moisture and weathering, allowing it to be used in various weather conditions without compromising its structural integrity. This flexibility enables more efficient construction scheduling, reducing downtime and potential cost overruns. Lastly, steel formwork can support greater concrete pouring heights and pressures, enabling faster construction and increased productivity. This can result in accelerated project timelines and reduced labor costs. In conclusion, while steel formwork may have a higher initial cost, its durability, reusability, improved finishes, precision, resistance to weathering, and ability to support larger concrete pours can lead to significant cost savings in terms of material, labor, and time. Therefore, steel formwork has a positive impact on the overall project cost estimation.

- Q: What are the different types of reinforcement used in steel formwork systems?

- There are several types of reinforcement commonly used in steel formwork systems, including steel bars, mesh, and fibers. Steel bars, also known as rebars, are often used to provide structural strength and support within the formwork. Steel mesh, on the other hand, is typically used to distribute loads evenly and prevent cracking. Lastly, steel fibers can be added to the concrete mix to enhance its tensile strength and improve resistance to cracking and shrinkage.

- Q: Can steel formwork be used for precast concrete tanks?

- Yes, steel formwork can be used for precast concrete tanks. Steel formwork offers strength, durability, and flexibility, making it suitable for constructing various types of precast concrete structures, including tanks.

- Q: How does steel formwork affect the overall acoustics of the building?

- Steel formwork does not directly affect the overall acoustics of a building as it is primarily used as a temporary structure during construction. However, the choice of materials used for permanent building elements, such as walls, floors, and ceilings, can significantly impact the acoustics of the building.

- Q: What are the different types of steel formwork available?

- There are several types of steel formwork available in the construction industry, each with its own unique features and advantages. Some of the most common types include: 1. Modular steel formwork: This type of formwork consists of prefabricated steel panels that can be assembled and disassembled easily. It is customizable and can be used for various shapes and sizes of concrete structures. 2. Tunnel formwork: As the name suggests, tunnel formwork is used for constructing tunnels and underground structures. It is made of steel plates and is designed to withstand high pressure and provide a smooth finish to the concrete. 3. Climbing formwork: This type of formwork is used for tall structures like skyscrapers. It is designed to be lifted and moved vertically as the construction progresses. Climbing formwork provides safety and efficiency while constructing multi-story buildings. 4. Steel soldier formwork: This is a versatile and cost-effective type of formwork that is commonly used for walls and columns. It is made of steel beams and soldiers and can be easily adjusted to different heights and widths. 5. Steel frame formwork: This type of formwork is made of steel frames with plywood or metal panels attached to it. It is lightweight, easy to handle, and provides a smooth finish to the concrete. 6. Steel table formwork: This is a type of formwork that is used for large horizontal slabs. It consists of steel tables that are supported by props or scaffolding. Steel table formwork is quick to assemble and dismantle, making it ideal for projects with tight timelines. These are just a few examples of the different types of steel formwork available. The choice of formwork depends on the specific requirements of the construction project, such as the type of structure, load-bearing capacity, and desired finish.

- Q: How does steel formwork handle different concrete surface protection methods?

- Steel formwork is a versatile and durable option for constructing concrete structures, and it can easily handle different concrete surface protection methods. The formwork itself is typically made of steel plates or frames that provide a strong and rigid support structure for the wet concrete. When it comes to protecting the concrete surface, there are various methods that can be employed, such as applying surface coatings, using form release agents, or using various types of form liners. Steel formwork can easily accommodate these methods and ensure their effectiveness. For instance, if a surface coating is being applied to protect the concrete, steel formwork can provide a smooth and uniform surface that allows for even and consistent application of the coating. The steel formwork is resistant to damage from the coating materials and can withstand the pressure and weight of the wet concrete while the coating cures. Similarly, when using form release agents, steel formwork can ensure proper adhesion and prevent any sticking or bonding between the concrete and the formwork. The smooth and non-porous surface of steel formwork allows for easy application and removal of the form release agents, ensuring a clean and protected concrete surface. Furthermore, steel formwork can accommodate the use of various types of form liners, which are used to create decorative or textured finishes on the concrete surface. The form liners can be easily attached to the steel formwork to create the desired texture or pattern, and the sturdy nature of steel ensures that the form liners remain securely in place during the pouring and curing process. In summary, steel formwork is highly compatible with different concrete surface protection methods. Its strength, durability, and versatility allow for easy application of coatings, form release agents, and form liners, ensuring a well-protected and aesthetically pleasing concrete surface.

- Q: What are the different types of steel formwork accessories available?

- There are several different types of steel formwork accessories available in the market. These accessories are designed to enhance the efficiency and effectiveness of steel formwork systems and make the construction process smoother. Some of the common types of steel formwork accessories include: 1. Formwork clamps: These clamps are used to secure the formwork panels together, ensuring stability and preventing any movement during the concrete pouring process. They come in various sizes and shapes to fit different formwork systems. 2. Formwork ties: These are used to hold the formwork panels together and provide additional support. Formwork ties are available in different lengths and materials to accommodate various formwork requirements. 3. Formwork connectors: These connectors are used to join the formwork panels at corners or intersections. They provide a strong and secure connection, ensuring proper alignment and stability of the formwork system. 4. Formwork wedges: These wedges are used to adjust the formwork panels and provide the desired level of inclination or angle. They are typically made of steel and can be easily inserted or removed to achieve the desired formwork configuration. 5. Formwork brackets: These brackets are used to support the formwork panels vertically or horizontally. They are adjustable and can be easily installed or removed to accommodate different formwork configurations. 6. Formwork spacers: These spacers are used to maintain a specific spacing between the formwork panels. They ensure consistent concrete thickness and prevent any bulging or deformation during the pouring process. 7. Formwork props: These props are used to support the formwork system and provide additional stability. They are adjustable in height and can be easily installed or removed as required. 8. Formwork anchors: These anchors are used to secure the formwork system to the ground or the existing structure. They provide stability and prevent any movement during the concrete pouring and curing process. Overall, these steel formwork accessories play a crucial role in ensuring the structural integrity and stability of the formwork system. They are designed to withstand high pressure and provide a reliable and efficient solution for construction projects.

- Q: Are there any specific safety measures to be followed during steel formwork installation?

- Yes, there are specific safety measures that should be followed during steel formwork installation. Here are some of the most important ones: 1. Personal Protective Equipment (PPE): All workers involved in the installation of steel formwork should wear appropriate PPE, including safety helmets, gloves, safety glasses, and steel-toed boots. This will help protect against potential head injuries, hand injuries, eye injuries, and foot injuries. 2. Training and Competency: Workers should be properly trained and competent in the installation of steel formwork. They should have a good understanding of the equipment being used, the proper installation techniques, and the potential hazards associated with the work. 3. Equipment Inspection: Before starting the installation process, all formwork equipment, including steel frames, braces, and connectors, should be inspected for any damage or defects. Any damaged or defective equipment should be taken out of service and replaced. 4. Secure and Stable Platform: A secure and stable platform should be established for workers to safely install the steel formwork. This may involve the use of scaffolding or other supporting structures. The platform should be properly erected and inspected for stability before work begins. 5. Fall Protection: Fall protection measures should be in place to prevent workers from falling while installing the steel formwork. This may include the use of guardrails, safety harnesses, and safety nets. Workers should be properly trained in the use of fall protection equipment and procedures. 6. Lifting and Handling: Proper lifting and handling techniques should be used when moving and positioning steel formwork. Workers should avoid overexertion and use mechanical aids, such as cranes or hoists, when necessary. Additionally, workers should be mindful of their posture and avoid awkward or strenuous lifting positions. 7. Communication and Coordination: Effective communication and coordination among workers is crucial during steel formwork installation. This includes clear instructions, proper signaling, and a designated person in charge of coordinating the work. This will help prevent accidents and ensure a smooth and safe installation process. By following these safety measures, the risk of accidents and injuries during steel formwork installation can be significantly reduced, creating a safer working environment for all involved.

- Q: Is steel formwork suitable for projects with heavy concrete loads?

- Yes, steel formwork is highly suitable for projects with heavy concrete loads. Steel formwork is known for its strength, durability, and load-bearing capacity, making it ideal for projects that involve heavy concrete loads. Steel formwork can withstand the pressure and weight of the concrete, ensuring that it maintains its shape and integrity throughout the pouring and curing process. Additionally, steel formwork offers excellent dimensional accuracy, allowing for precise and consistent concrete placement, which is crucial for projects with heavy loads. Overall, steel formwork is a reliable and robust choice for projects that require the support of heavy concrete loads.

- Q: How is steel formwork cleaned and maintained?

- Steel formwork can be cleaned and maintained by removing any concrete residue using a high-pressure water jet or wire brush. After cleaning, it should be inspected for any damages or rust, and if found, repaired or repainted accordingly. Regular lubrication of moving parts and proper storage in a dry environment also helps to extend its lifespan.

Send your message to us

Climbing-Bracket CB240 and CB210 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches