Climbing Bracket CB240 & CB210 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

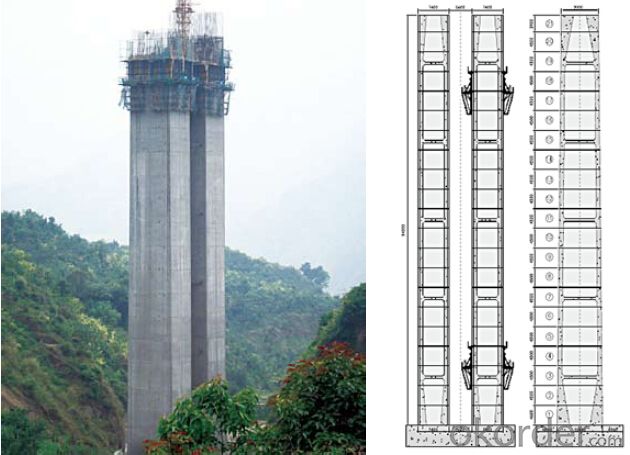

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: Is steel formwork suitable for projects with high concrete pressure?

- Indeed, steel formwork proves to be a suitable choice for projects that involve high concrete pressure. Renowned for its robustness and durability, steel formwork possesses the ability to withstand the immense pressure exerted by the wet concrete during both pouring and curing stages. It effectively bears the weight and pressure of the concrete, preventing any deformation or collapse, thus ensuring the structure's stability and integrity throughout the construction process. Furthermore, steel formwork guarantees a smooth and uniform surface finish for the concrete, which is crucial for projects that demand top-notch quality. Moreover, its reusability feature makes it a cost-effective option for projects that entail high concrete pressure.

- Q: How does steel formwork affect the overall constructability of the structure?

- The overall constructability of a structure is greatly enhanced by the use of steel formwork. Firstly, the high strength and durability of steel formwork enable it to withstand the pressure and forces exerted during the concrete pouring and curing process. This strength allows for the construction of taller and more complex structures, providing greater design flexibility. Furthermore, the reusability of steel formwork significantly reduces construction time and costs. Unlike traditional wooden formwork, steel formwork can be easily dismantled, cleaned, and reassembled for future concrete pours. This eliminates the need for continuous formwork fabrication, resulting in faster construction cycles and increased productivity. In addition, steel formwork ensures excellent dimensional accuracy and stability. The rigid structure of steel formwork allows for precise pouring and shaping of concrete according to desired dimensions, resulting in a more accurate and seamless end product. This accuracy is particularly important for high-quality construction, especially in critical elements such as walls, columns, and beams. Moreover, steel formwork offers superior surface finishes and better concrete quality. Its smooth and non-absorbent surface prevents water leakage or seepage from the concrete, resulting in a higher-quality finish. This is particularly beneficial for structures that require high aesthetic appeal or exposed concrete surfaces. Lastly, steel formwork enhances safety on construction sites. Its robust structure and stability reduce the risk of accidents during the concrete pouring and formwork removal processes. Steel formwork also allows for easier access and movement of workers, ensuring safe and efficient task performance. In conclusion, steel formwork significantly improves the constructability of structures. Its strength, reusability, dimensional accuracy, surface finish, and safety benefits make it a preferred choice for construction projects. By utilizing steel formwork, construction processes become more efficient, cost-effective, and reliable, resulting in a higher-quality end product.

- Q: What are the different types of joints used in steel formwork construction?

- There are several different types of joints used in steel formwork construction, including butt joints, lap joints, groove joints, and tongue and groove joints. These joints are designed to provide stability and strength to the formwork system, allowing it to withstand the pressure exerted by the concrete during the pouring and curing process.

- Q: How does steel formwork affect the overall construction cost estimate?

- Steel formwork can have a significant impact on the overall construction cost estimate. While steel formwork may have a higher initial cost compared to other types of formwork, it offers several advantages that can offset this expense. Steel formwork is durable, reusable, and can be easily assembled and disassembled, resulting in reduced labor costs and increased efficiency. Additionally, steel formwork provides a smooth surface finish, which can minimize the need for additional surface treatments, saving both time and money. Overall, although steel formwork may require a higher upfront investment, its long-term benefits can lead to cost savings in the construction process.

- Q: How does steel formwork contribute to the overall safety of workers?

- There are several ways in which steel formwork contributes to the overall safety of workers. Firstly, its strength and durability provide a stable and secure structure for workers to perform their tasks, minimizing the risk of accidents and collapses. In addition, steel formwork is fire-resistant, offering protection in case of fire emergencies. This feature significantly reduces the risk of injuries and gives workers valuable time to safely evacuate the area. Furthermore, steel formwork is designed to withstand various weather conditions, such as strong winds and heavy rains. This resistance prevents instability or collapse during adverse weather, minimizing the risk of accidents and injuries for workers on-site. Moreover, steel formwork includes safety features like non-slip surfaces and handrails, which enhance worker safety by providing better grip and stability when moving around the structure. These features help prevent common accidents like slips, trips, and falls on construction sites. Another important aspect is that steel formwork is reusable and easy to assemble and disassemble. This reduces the need for workers to carry heavy materials or tools, decreasing the risk of strain injuries and fatigue-related accidents. Lastly, steel formwork is designed to ensure proper support and alignment during concrete pouring, minimizing the risk of structural failures or collapses. This precise alignment guarantees the stability of the structure and reduces the likelihood of accidents that could endanger workers' safety. In conclusion, steel formwork is crucial for enhancing the overall safety of workers. Its strength, durability, fire resistance, weather resistance, non-slip surfaces, and proper support significantly contribute to creating a secure working environment and reducing the risk of accidents, injuries, and structural failures.

- Q: What are the different types of formwork bracing used in steel formwork?

- There are several different types of formwork bracing used in steel formwork, each providing unique features and benefits. Here are some of the most common types: 1. Adjustable Steel Bracing: This type of bracing consists of adjustable steel tubes or rods that can be easily extended or retracted to the desired length. It allows for quick and easy installation and adjustment, making it ideal for projects with varying formwork heights. 2. Cross Bracing: Cross bracing, as the name suggests, involves diagonal steel members that are placed to form an "X" shape between vertical supports. It provides lateral stability to the formwork system and helps prevent buckling or deformation. 3. Tie Rod Bracing: Tie rod bracing involves the use of threaded steel rods that are connected through formwork panels to provide additional strength and stability. It is commonly used in large-scale formwork systems where high loads need to be supported. 4. External Bracing: External bracing is often used in taller formwork structures to provide increased stability against wind forces. It involves installing steel members on the exterior side of the formwork system to resist lateral movement and maintain structural integrity. 5. Kickers: Kickers are diagonal bracing elements that are installed between formwork panels and the ground or a solid anchor point. They help transfer the lateral forces and prevent the formwork from tilting or collapsing. 6. Strut Bracing: Strut bracing involves the use of steel struts or props that are placed vertically between the formwork panels and the ground. It provides additional support to prevent horizontal movement and ensure the stability of the formwork system. 7. Flying Bracing: Flying bracing is used in situations where formwork needs to be supported from above, such as in bridge construction or overhead structures. It involves suspending bracing elements from overhead supports to provide stability and prevent formwork deformation. Each type of formwork bracing has its advantages and is chosen based on the specific requirements of the project, including the height and size of the formwork, expected loads, and site conditions. A combination of different bracing types may also be used to provide optimal stability and safety.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- Steel formwork is not typically used for structures with high thermal insulation requirements. This is because steel is a good conductor of heat, meaning it allows heat to easily transfer through it. As a result, using steel formwork in structures that require high thermal insulation would lead to significant heat loss, reducing the overall energy efficiency of the building. To achieve high thermal insulation, materials with good thermal resistance such as insulating concrete forms (ICFs), expanded polystyrene (EPS), or other insulated formwork systems are preferred. These materials have low thermal conductivity and provide a barrier against heat transfer. By using such materials, structures can meet the high thermal insulation requirements and improve energy efficiency. However, it is worth mentioning that steel formwork can still be used in combination with insulation materials to provide structural support and form the shape of the structure. In this case, additional insulation measures, such as applying insulation layers or using insulation inserts, would be necessary to enhance the thermal performance of the structure. Overall, while steel formwork can be suitable for many construction projects, it is not the ideal choice for structures with high thermal insulation requirements.

- Q: Can steel formwork be used for swimming pool construction?

- Swimming pool construction can utilize steel formwork, which is a versatile and durable choice commonly employed in the construction industry for various purposes. Steel formwork offers numerous benefits, such as high strength, stability, and reusability, making it ideal for constructing swimming pool walls, floors, and other structures. By employing steel formwork, a smooth and precise finish is achieved, ensuring uniformity in the appearance of swimming pool walls and floors. It can withstand the water pressure, ensuring the structural integrity of the pool. Furthermore, steel formwork is easily assembled and disassembled, facilitating efficient construction and maintenance. Additionally, steel formwork is highly adaptable and can be customized to meet specific design requirements. It accommodates the construction of various shapes and sizes of swimming pools, including both in-ground and above-ground options. This adaptability makes steel formwork the preferred choice for swimming pool construction projects. Nevertheless, when employing steel formwork for swimming pool construction, certain factors must be considered. Proper waterproofing measures must be implemented to prevent water leakage and corrosion of the steel. Adequate reinforcement and support are also necessary to ensure the stability and durability of the pool structure. In conclusion, steel formwork is a suitable option for swimming pool construction due to its strength, durability, and versatility. Proper usage, in combination with appropriate waterproofing and reinforcement measures, can result in a robust and visually pleasing swimming pool.

- Q: How does steel formwork contribute to the overall strength of a structure?

- Steel formwork is a construction technique that involves using steel panels and frames to create temporary molds for pouring concrete. This method offers numerous advantages over traditional wooden formwork, especially in terms of enhancing the overall strength of a structure. Firstly, steel formwork provides exceptional durability and resistance to wear and tear. Steel is a sturdy and robust material that can withstand heavy loads and extreme weather conditions. Unlike wooden formwork, steel formwork does not warp, crack, or deteriorate over time, ensuring that the structure maintains its strength and integrity for a longer period. Moreover, steel formwork offers better dimensional stability compared to other materials. The steel panels and frames are fabricated with precision, ensuring accurate measurements and consistent shapes. This precision allows for a more even distribution of concrete, resulting in a structure that is stronger and less prone to cracks or weaknesses. Additionally, steel formwork allows for greater flexibility in design and construction. The strength of steel enables the creation of complex and intricate structures that may not be achievable with other formwork materials. The versatility of steel formwork allows engineers to design structures with unique shapes and configurations, enhancing their overall strength and load-bearing capacity. Furthermore, steel formwork contributes to the overall strength of a structure by providing excellent support and reinforcement during the concrete pouring process. The steel panels and frames act as a framework, holding the concrete in place until it solidifies and gains strength. This ensures that the concrete cures properly and optimally, resulting in a structure that is structurally sound and resilient. In conclusion, steel formwork plays a crucial role in enhancing the overall strength of a structure. Its durability, dimensional stability, flexibility in design, and support during the concrete pouring process all contribute to creating a robust and long-lasting structure. By opting for steel formwork, construction projects can achieve higher levels of strength, durability, and structural integrity.

- Q: What are the different types of tie systems used in steel formwork?

- In construction projects, various tie systems are commonly employed in steel formwork to ensure stability and support during the concrete pouring process. The primary types of tie systems utilized in steel formwork are as follows: 1. Tie rods and wing nuts: This tie system is extensively used in steel formwork. It involves the insertion of steel rods through the formwork panels, which are then secured using wing nuts. This system allows for convenient and effortless assembly and disassembly of the formwork. 2. Shear connectors: In situations where there is a requirement to transfer shear forces between the formwork and the concrete, shear connectors are employed. These connectors usually consist of steel bars embedded in the concrete and connected to the formwork. 3. Steel form ties: Steel form ties are used to hold the formwork panels together, maintaining the desired shape and alignment during concrete pouring. These ties are typically constructed from steel and are available in various lengths and sizes to cater to diverse formwork requirements. 4. Adjustable formwork systems: Designed to offer flexibility in adjusting the formwork to different shapes and sizes, these systems often incorporate adjustable brackets and clamps. They allow for effortless and precise alignment of the formwork panels. 5. Stay-in-place formwork systems: Stay-in-place formwork systems are specifically designed to remain in place even after the concrete has cured, eliminating the need for formwork removal. These systems find application in scenarios where the formwork is intended to become a permanent part of the structure, such as in bridges or tunnels. Overall, the selection of a tie system in steel formwork depends on factors such as project requirements, structural design, and specific construction site conditions. It is crucial to choose a tie system that can provide the required stability and support for the formwork, while also considering factors such as ease of installation, reusability, and cost-effectiveness.

Send your message to us

Climbing Bracket CB240 & CB210 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches