Climbing-Bracket CB240 & CB210 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

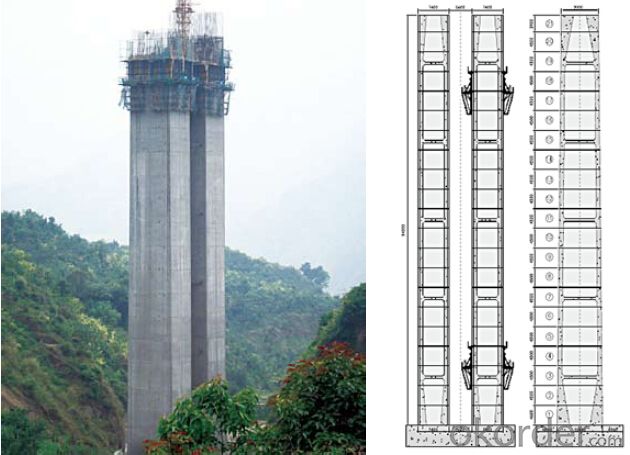

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: What are the standard sizes of steel formwork panels?

- The construction project's specific requirements and the manufacturer can cause variation in the standard sizes of steel formwork panels. Nevertheless, the industry commonly uses certain standard sizes. In general, steel formwork panels are rectangular and have dimensions that range from 1.2 meters to 2.4 meters in width and 1.8 meters to 3.6 meters in height. These standard sizes are designed to accommodate different construction needs and offer flexibility in forming walls, columns, slabs, and beams. The thickness of steel formwork panels can also vary, typically ranging from 12mm to 20mm. Thicker panels may be used for heavy-duty purposes or to enhance strength and durability against the pressure exerted by concrete during pouring. It is important to note that while these sizes are commonly used, custom sizes can also be manufactured to meet specific project requirements. Furthermore, some manufacturers may provide modular formwork systems that allow easy assembly and disassembly by combining standard-sized panels in various configurations. Ultimately, the choice of steel formwork panel size depends on factors such as the size and complexity of the structure being formed, the required load-bearing capacity, and the ease of transportation and handling on the construction site.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- Steel formwork is used in construction projects to provide a temporary structure that holds the concrete in place until it sets and hardens. One of the key benefits of using steel formwork is that it prevents the concrete mixture from separating during the pouring process. The steel formwork is carefully designed and constructed to create a tight enclosure for the concrete, ensuring that it remains in its desired shape and consistency. It is made up of steel panels and frames that are securely fastened together to create a rigid structure. When the concrete mixture is poured into the steel formwork, it is held in place by the walls of the formwork itself. The steel panels and frames provide a smooth and even surface for the concrete to be poured onto, preventing any separation or segregation of the mixture. Furthermore, the steel formwork is designed with properly aligned joints and connections, which further helps in preventing any leakage or seepage of the concrete mixture. This ensures that the concrete remains intact and does not separate into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork is capable of withstanding the pressure exerted by the weight of the concrete. This prevents any deformation or movement of the formwork during the pouring process, which could potentially cause the concrete to separate or shift. Overall, the use of steel formwork provides a strong and stable structure that prevents the concrete mixture from separating during pouring. It ensures that the concrete remains in its desired form and consistency, resulting in a high-quality and durable finished product.

- Q: Are there different sizes of steel formwork available?

- Yes, there are different sizes of steel formwork available.

- Q: How does steel formwork prevent concrete spalling?

- Steel formwork prevents concrete spalling by providing a strong and rigid structure that holds the concrete in place during the curing process. When concrete is poured into steel formwork, it takes the shape of the structure and hardens over time. The steel formwork ensures that the concrete is supported and does not sag or slump, which can lead to uneven curing and cracking. Concrete spalling occurs when the surface of the concrete flakes or chips away, exposing the underlying layers. This can happen due to a variety of reasons, including moisture penetration, freeze-thaw cycles, and chemical reactions. Steel formwork helps prevent spalling by creating a barrier that protects the concrete from these external factors. The tight fit of steel formwork prevents water from seeping into the concrete, reducing the risk of moisture-related spalling. Additionally, steel formwork provides insulation against temperature changes, minimizing the effects of freeze-thaw cycles. These cycles occur when water penetrates the concrete, freezes, and expands, leading to cracking and spalling. By maintaining a consistent temperature, steel formwork helps prevent these damaging cycles. Moreover, steel formwork acts as a shield against chemical reactions that can cause spalling. Certain chemicals, such as sulfates or chlorides, can react with the concrete and break down its structure, leading to spalling. Steel formwork creates a physical barrier that prevents these chemicals from directly contacting the concrete, minimizing the risk of spalling. Overall, steel formwork plays a crucial role in preventing concrete spalling by providing a sturdy structure that supports the concrete during curing, protecting it from moisture, temperature changes, and chemical reactions. Its strength and durability ensure that the concrete remains intact, reducing the risk of spalling and extending the lifespan of the structure.

- Q: Can steel formwork be used for water storage tanks?

- Water storage tanks can indeed utilize steel formwork. Because of its strength, durability, and ability to withstand water pressure and weight, steel formwork is a popular choice. Its purpose is to create a sturdy structure that securely holds the concrete in place during the setting process, resulting in a robust and leakproof tank. Moreover, steel formwork is convenient to assemble and disassemble, making it a versatile option for tanks of different sizes and shapes. Nevertheless, it is crucial to ensure proper coating or treatment to prevent corrosion caused by water and external factors.

- Q: Can steel formwork be used for precast concrete beams with complex geometries?

- Yes, steel formwork can be used for precast concrete beams with complex geometries. Steel formwork offers numerous advantages for creating complex shapes and designs in precast concrete beams. Steel is a strong and durable material that can withstand the pressures and forces exerted during the concrete pouring and curing process. It can be easily fabricated to create the desired shape and size of the beam, making it suitable for complex geometries. Steel formwork also provides excellent dimensional accuracy, ensuring that the precast concrete beams maintain their intended shape and dimensions. This is particularly important for beams with complex geometries, as any slight variation in shape could affect their structural integrity. Additionally, steel formwork offers a smooth and high-quality finish to the concrete surface. This is essential for beams with complex geometries, as a smooth surface ensures proper load distribution and reduces the risk of cracking or other structural issues. Furthermore, steel formwork can be reused multiple times, making it a cost-effective option for creating precast concrete beams with complex geometries. The versatility and durability of steel formwork make it a preferred choice for many construction projects, including those involving complex precast concrete beams. In conclusion, steel formwork is a suitable and practical choice for creating precast concrete beams with complex geometries. Its strength, durability, dimensional accuracy, and smooth finish make it an ideal solution for achieving the desired shape and design in these beams.

- Q: How does steel formwork contribute to the overall sustainability of the construction industry?

- There are several ways in which steel formwork contributes to the overall sustainability of the construction industry. Firstly, its durability and long-lasting nature allow for multiple reuses, reducing the need for new formwork materials each time a construction project is undertaken. This, in turn, significantly reduces waste generation during the construction process and minimizes the industry's overall environmental impact. In addition, steel formwork offers a more sustainable alternative to traditional materials like timber. The use of timber often involves cutting down trees, leading to deforestation and habitat destruction. By opting for steel formwork, we can decrease our reliance on timber and contribute to the preservation of forests. Moreover, steel formwork provides greater structural stability and strength compared to other materials. This enables more efficient construction processes and reduces the necessity for additional support structures. Consequently, less material is wasted, energy is conserved, and the overall construction time is shortened, resulting in a more sustainable process. Furthermore, steel formwork exhibits exceptional resistance to weather conditions, corrosion, and fire. This ensures the longevity of buildings, thus reducing the need for frequent repairs or replacements. By utilizing steel formwork, we can construct structures with extended lifespans, leading to reduced resource consumption and waste generation over time. Lastly, steel formwork is recyclable. At the end of its lifecycle, it can be easily melted down and repurposed for other applications. This diminishes the demand for new steel production, conserves natural resources, and lowers energy consumption. To sum up, steel formwork's durability, reusability, resistance to weather conditions, and recyclability all contribute to the overall sustainability of the construction industry. By minimizing waste generation, deforestation, energy consumption, and resource depletion, its use proves to be an environmentally-friendly choice for construction projects.

- Q: What are the considerations when designing steel formwork for architectural canopies?

- When designing steel formwork for architectural canopies, several important considerations need to be taken into account. These include: 1. Structural Integrity: The formwork must be designed to withstand the loads imposed by the canopy, including dead loads (self-weight), live loads (such as wind and snow), and any other potential loads such as hanging fixtures. The steel formwork should be structurally robust to ensure the stability and safety of the canopy. 2. Aesthetic Appeal: Architectural canopies are often designed to enhance the overall visual appeal of a building. Therefore, the steel formwork should be designed in a way that complements the desired aesthetics of the canopy. This could involve incorporating decorative elements, such as patterns or textures, into the formwork design. 3. Ease of Installation: The formwork should be designed for easy and efficient installation. This could involve using modular components that can be assembled quickly and easily on-site. It is also important to consider the weight and size of the formwork elements to ensure they can be handled and installed safely. 4. Durability and Maintenance: Steel formwork should be designed to withstand the environmental conditions to which it will be exposed. This may include protection against corrosion, UV radiation, and other potential causes of deterioration. Additionally, the formwork should be designed for easy maintenance and repair, if necessary. 5. Functionality: The formwork must be designed to accommodate any specific functional requirements of the canopy. This could include providing space for utility connections, such as lighting or drainage systems, or incorporating features such as rainwater collection systems. 6. Cost-effectiveness: The design of the steel formwork should consider the overall cost of the canopy project. This includes not only the initial cost of the formwork itself but also factors such as ease of transportation and installation, as well as long-term maintenance costs. Overall, the design of steel formwork for architectural canopies requires a careful balance between structural integrity, aesthetics, functionality, and cost-effectiveness. By considering these considerations, architects and engineers can ensure the successful implementation of canopies that are both visually appealing and structurally sound.

- Q: Can steel formwork be used in tunnel construction projects?

- Yes, steel formwork can be used in tunnel construction projects. Steel formwork is a popular choice in tunnel construction due to its durability, strength, and reusability. It provides a robust framework for pouring concrete and helps to achieve precise and accurate dimensions in tunnel construction. Steel formwork can withstand the pressure of the surrounding soil and the weight of the concrete, ensuring the stability and safety of the tunnel structure. Additionally, steel formwork is resistant to corrosion and has a longer lifespan compared to other types of formwork, making it an ideal choice for long-term tunnel construction projects.

- Q: Is steel formwork suitable for projects with high concrete temperature requirements?

- Projects with high concrete temperature requirements generally do not consider steel formwork to be suitable. This is due to the fact that steel has a high thermal conductivity, which allows it to rapidly transfer and dissipate heat. When exposed to high concrete temperatures, steel formwork can become extremely hot and may deform, warp, or fail. On the other hand, materials like timber or plastic formwork, which have lower thermal conductivity, are more appropriate for projects with high concrete temperature requirements. These materials provide better insulation and can handle the increased heat without compromising their structural integrity. However, it is important to note that there are specific types of steel formwork that are designed to withstand higher concrete temperatures. These specialized formwork systems are typically made from heat-resistant alloys or have additional insulation layers to minimize the impact of temperature on the steel. Ultimately, the suitability of steel formwork for projects with high concrete temperature requirements depends on the specific type of steel formwork being used and its ability to effectively withstand and dissipate heat. It is recommended to consult with structural engineers and formwork suppliers to determine the most appropriate formwork material for such projects.

Send your message to us

Climbing-Bracket CB240 & CB210 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches