PVC Waterproof Rolling Membranes For Roof With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The P series waterproofing membrane is a heatweldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

Application Scope

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc

Features and Benefits:

l High Strength

l Hot-air welded seams for long-term performance

l Proven membrane performance

l Excellent resistance to plasticizer extraction and migration performance.

Advantagee

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

9.Excellent Quality+ Competitive Cost+ High Productivity +Brand Management +Good Customer Service

10.Strong tensile strength, high elongation, excellent anti-extreme weather property, suitable for exposed projects with long lifetime and good anti-aging property, can be welded firmly, outstanding root penetration resistance, simple and fast construction without pollution, great plasticity and fast treatment with corners and details, etc.

Actually, for all the features listed like above, I’m sure every waterproofing manufacturer would like to use them for the description of their products. But whether surely their products can live up the standards and fill your requirements, it’s a question.

Packaging:

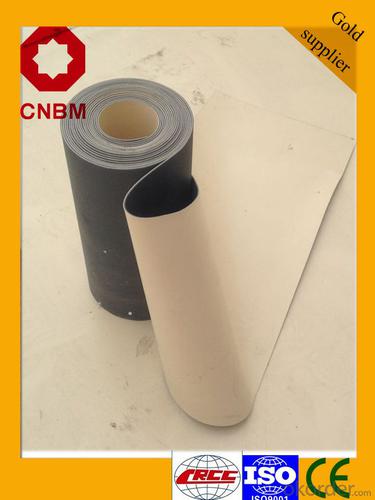

The rolls of P series waterproofing membrane are wrapped in a protective film and strapped to a wood pallet. The P series waterproofing membrane lengths of 15m, 20m, 25m, widths of 1.03m, 2.05m and thicknesses of 1.20mm, 1.50mm, 1.80mm, 2.00mm or customized according to customers requirements.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

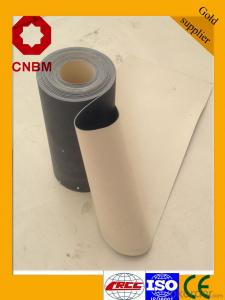

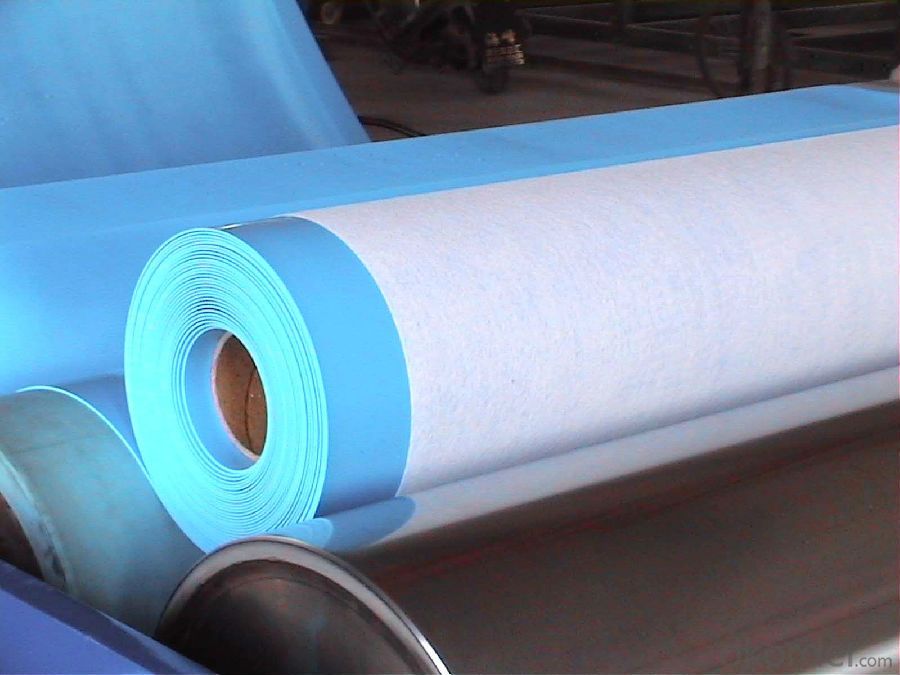

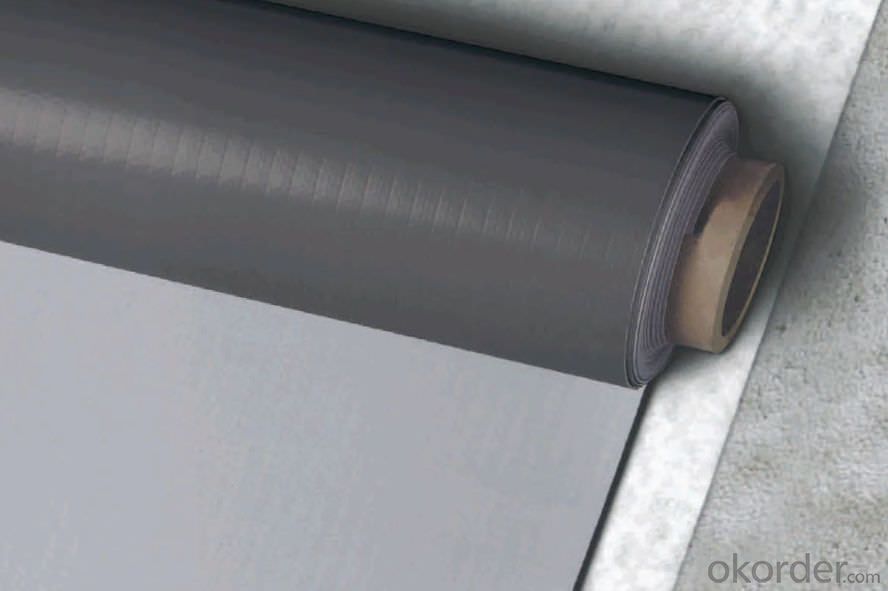

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can be used on roofs with skylights. The membrane is typically installed around the skylight opening to ensure a watertight seal and prevent any leaks or water damage.

- Q: Can a waterproofing membrane be painted over?

- Yes, a waterproofing membrane can be painted over. However, it is important to ensure that the membrane is clean, dry, and free from any debris or loose material before applying paint. Additionally, it is recommended to use a paint that is specifically designed for use on waterproofing membranes to ensure proper adhesion and longevity. It is also important to follow the manufacturer's instructions for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used on wood block surfaces?

- Certainly! Waterproofing membranes are a suitable option for safeguarding wood block surfaces. The utilization of a waterproofing membrane on wood block surfaces, like decks or wooden floors, can prove advantageous by shielding against water damage and prolonging the wood's lifespan. These membranes function as a barrier, effectively preventing water from infiltrating the wood and causing deterioration, such as rot, warping, or decay, over time. To guarantee optimal outcomes, it is crucial to select a waterproofing membrane explicitly designed for wood surfaces and adhere to the manufacturer's instructions for application. By doing so, the wood block surface can be adequately protected and maintained, ensuring its resilience and longevity.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to provide a protective barrier against water infiltration, which is crucial for the longevity and maintenance of buildings. They are particularly effective in areas prone to heavy rainfall or where water exposure is a concern, making them suitable for shopping malls and commercial buildings where water damage can be costly and disruptive.

- Q: The difference between high polymer modified asphalt waterproofing membrane and sbs

- SBS modified asphalt waterproofing membrane is SBS rubber modified petroleum asphalt cited as the invasion coating, polyester fiber non-woven fabrics, jute cloth, fiberglass mats were made for the fetal base, the plastic film for the anti-sticking isolation Layer, by the selection, ingredients, eutectic, invasion, composite molding, curling and other processes processing production.

- Q: Can a waterproofing membrane be tiled over?

- Yes, a waterproofing membrane can be tiled over. Tiling over a waterproofing membrane provides an additional layer of protection against water damage and helps create a durable and moisture-resistant surface.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to wear proper personal protective equipment (PPE) such as gloves, goggles, and a respirator to protect against potential chemical exposure and inhalation of fumes. Additionally, ensure adequate ventilation in the work area to prevent the buildup of fumes. It is also crucial to follow the manufacturer's instructions and guidelines for installation to minimize the risk of accidents or improper application. Lastly, be cautious of potential hazards such as slippery surfaces, sharp edges, or working at heights, and take necessary precautions to prevent falls or injuries.

- Q: Are waterproofing membranes resistant to mineral oils?

- Yes, waterproofing membranes are generally resistant to mineral oils.

- Q: Can waterproofing membranes be used on terraces?

- Terraces can definitely benefit from the use of waterproofing membranes. In fact, it is highly recommended to apply these membranes to protect the terrace's structural integrity and prevent any water damage. Waterproofing membranes act as a barrier, effectively stopping water from seeping into the terrace and causing undesirable leaks or cracks. They are commonly utilized on flat terraces, rooftop terraces, and even balconies to guarantee that water does not infiltrate the surface and cause harm to the underlying structure. Waterproofing membranes come in a variety of types, including liquid-applied, sheet, and self-adhesive membranes, offering diverse options that cater to the specific needs of the terrace. By applying a waterproofing membrane, the terrace can be safeguarded against moisture, UV rays, and other environmental factors, ultimately prolonging its lifespan and ensuring a resilient and long-lasting surface.

- Q: How to use self-adhesive waterproofing membrane?

- 7) on the interface seal: the use of additional self-adhesive seal seal. When sealing the interface, first remove the diaphragm on the surface of the membrane overlap parts, and then paste the additional self-adhesive seal. If the overlap is contaminated, clean it first. (When the upper and lower layers between the use of lap, no self-adhesive seal, lap width of not less than 60mm) 8) Self-adhesive waterproofing membrane in the wall when the paving, the coil should be temporarily sealed at the mouth (available tape or thickened cement slurry seal), to prevent the wall of the head of the water too quickly lost. 9) node to strengthen the processing: node in the large surface after the completion of the construction of reinforced processing.

Send your message to us

PVC Waterproof Rolling Membranes For Roof With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords