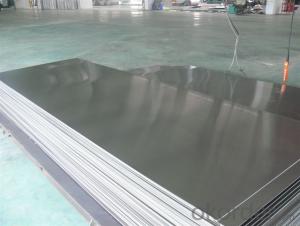

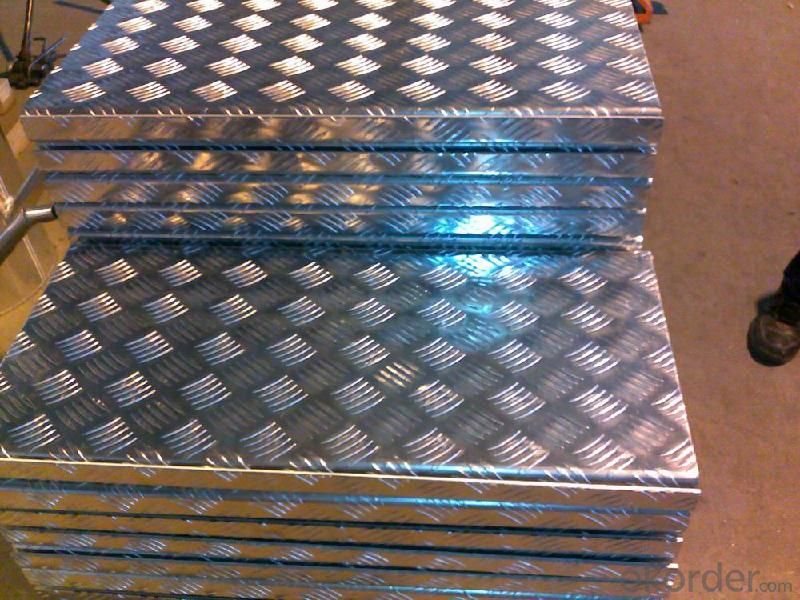

China Thin Aluminum Sheets - 3003 H122 Anti-Slip 3/5 Bars Embossed Diamond Aluminum Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of 3003 H122 Anti-slip 3/5Bars Embossed Diamond Aluminum Plate

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of 3003 H122 Anti-slip 3/5Bars Embossed Diamond Aluminum Plate

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

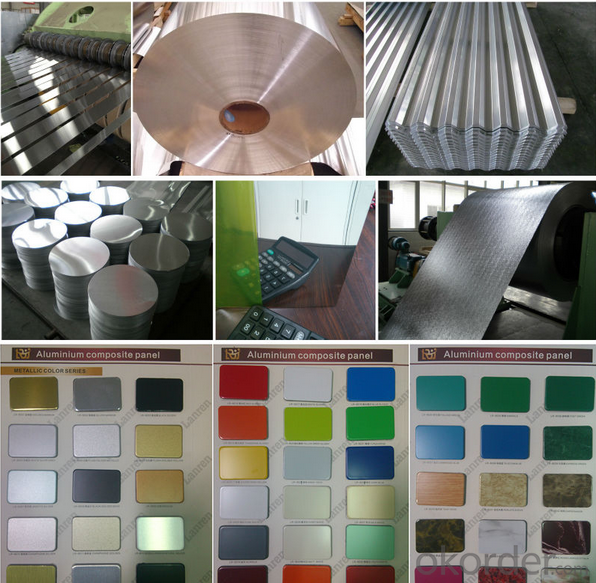

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Indeed, aluminum sheets prove to be a suitable material for the production of electrical enclosures. Within the manufacturing industry, aluminum is widely utilized due to its versatility and numerous advantages. To begin with, aluminum possesses a unique combination of lightweight properties and strength, making it an ideal choice for constructing enclosures that require durability without the burden of excessive weight. Its strength-to-weight ratio surpasses that of many other metals, allowing for the creation of sturdy enclosures without unnecessary bulkiness. Moreover, aluminum exhibits exceptional resistance to corrosion, a crucial attribute for electrical enclosures that may encounter various environmental conditions, such as moisture, humidity, or corrosive elements. The natural oxide layer present on aluminum acts as a protective barrier, ensuring the enclosures' longevity and reliability. Additionally, aluminum possesses excellent electrical conductivity, a vital characteristic for electrical enclosures. This property facilitates efficient dissipation of heat generated by electrical components, effectively preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is highly machinable and can be easily molded into different shapes and sizes. This inherent flexibility enables manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Finally, when considering cost-effectiveness, aluminum proves to be a more economical choice compared to other metals such as stainless steel or copper. It strikes a balance between affordability and performance, making it an attractive option for the manufacturing of electrical enclosures. In conclusion, the lightweight nature, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness of aluminum sheets make them a highly suitable material for the production of electrical enclosures.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: What is the difference between aluminum plate AL1050 and AL1060?

- 1050 and 1060 belong to an aluminum plate, that is, pure aluminum plate, the difference is that the content of aluminum is different. 1050 aluminum content 99.95%, 1060 Aluminum Content 99.60%, material is very close, often can replace the use, the current use is more than 1060 Aluminum plate.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Explain how aluminum sheets can impact the longevity and robustness of a building's structure.

- <p>Aluminum sheets can significantly enhance the durability of a building due to their corrosion resistance, lightweight nature, and high strength-to-weight ratio. They are resistant to weathering, which protects the building from environmental damage, and they do not rust, reducing the need for maintenance and repair. Additionally, aluminum's malleability allows for the creation of various shapes and sizes, making it versatile for different architectural designs. Its recyclability also contributes to sustainability, reducing the overall environmental impact of construction.</p>

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery. Aluminum is a versatile and widely used material in various industries, including machinery and manufacturing. Aluminum sheets offer several advantages that make them suitable for use in industrial machinery. Firstly, aluminum sheets are lightweight. Compared to other metals like steel, aluminum has a significantly lower density, making it ideal for applications where weight reduction is important. The lightweight nature of aluminum allows for easier handling, transportation, and installation of machinery components, resulting in higher efficiency and lower costs. Secondly, aluminum sheets are highly corrosion resistant. Aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This resistance to corrosion makes aluminum sheets suitable for use in industrial machinery, especially in environments where exposure to moisture, chemicals, or harsh weather conditions is common. Additionally, aluminum sheets have excellent thermal conductivity. This property allows aluminum to quickly and efficiently dissipate heat, making it suitable for applications where machinery components generate significant heat. By effectively managing heat, aluminum sheets help prevent overheating and prolong the lifespan of machinery. Furthermore, aluminum sheets are easily formable and can be fabricated into various shapes and sizes, making them adaptable to different machinery designs and requirements. They can be easily machined, welded, and joined, allowing for easy integration into industrial machinery manufacturing processes. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, reducing the environmental impact of industrial machinery production and disposal. In conclusion, aluminum sheets are suitable for industrial machinery due to their lightweight nature, corrosion resistance, thermal conductivity, formability, and sustainability. These qualities make aluminum sheets an excellent choice for various applications in the machinery and manufacturing industries.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum has excellent thermal conductivity properties, which allows it to effectively reflect heat and prevent the transfer of thermal energy. This makes it an ideal material for insulation jackets, as it helps to maintain temperature control and minimize heat loss or gain. Additionally, aluminum sheets are lightweight, durable, and resistant to corrosion, making them a practical choice for insulation applications.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q: Thickness of Aluminum Foil A rectangular sheet ofaluminum foil is 50 centimeters long and 20 centimeterswide, and weighs 5.4 grams. Find the thicknessof the aluminum foil in centimeters

- density Aluminum 2700 kg/m? Volume = 0.5 x 0.2 x d = 0.1d m? where d is thickness 5.4 g = 0.0054 kg 0.0054 kg / 2700 kg/m? = 2.0e-6 m? 2.0e-6 m? = 0.1d m? d = 2.0 e-5 m or 20 ?m or 0.02 mm or 0.002 cm .

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

- Q: How is the thickness of aluminum sheets measured?

- A micrometer is typically utilized to measure the thickness of aluminum sheets. This precision instrument consists of a calibrated screw mechanism featuring a spindle and anvil. To determine the thickness of an aluminum sheet, it is positioned between the spindle and anvil of the micrometer. By turning the screw, pressure is applied to firmly secure the sheet in place. The measurement can then be obtained by reading the scale or digital display on the micrometer. Alternatively, a thickness gauge is commonly employed for this purpose. This gauge employs a set of parallel anvils to measure the sheet's thickness. The sheet is inserted into the gap between the anvils, and the measurement can be obtained by reading the scale or display on the gauge. Both methods yield precise and dependable measurements of aluminum sheet thickness.

Send your message to us

China Thin Aluminum Sheets - 3003 H122 Anti-Slip 3/5 Bars Embossed Diamond Aluminum Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords