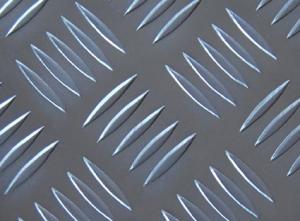

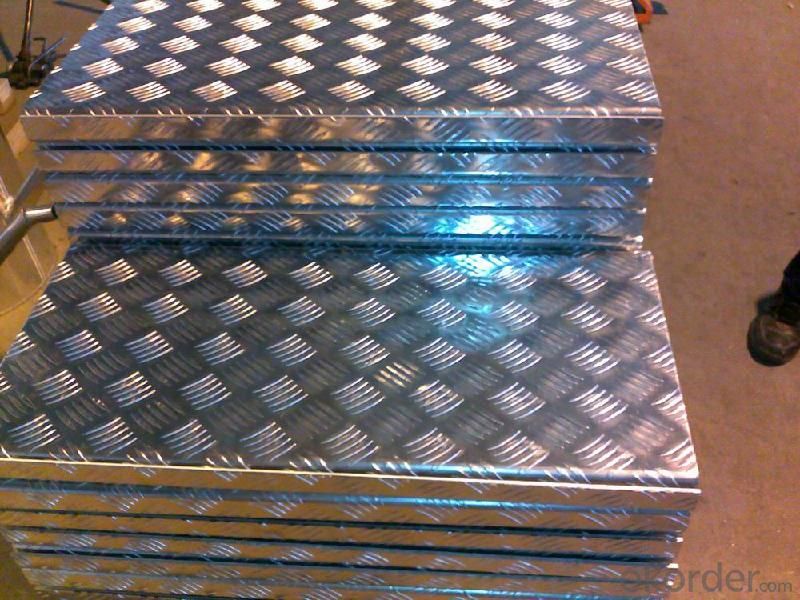

Mirror Diamond Embossed Aluminum Angle Cut Sheets 3003/5005/5052/5754

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

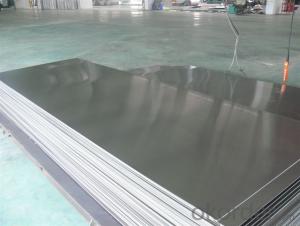

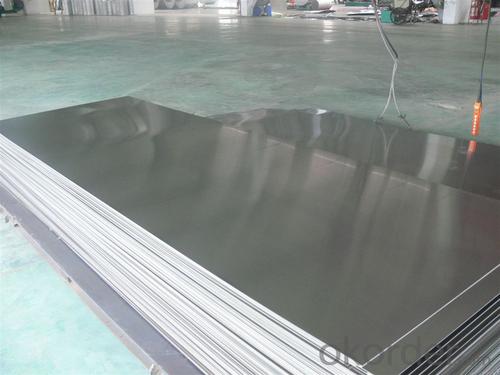

Mirror Diamond Embossed Aluminum Plate/Sheet 3003/5005/ 5052/5754

Description

Aluminium sheet | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

According to the composition of alloy, it can be divided into 5 items.

1) High purity aluminum plate (rolling by the content above 99.9 high purity aluminum)

2) Pure aluminum plate (rolled by pure aluminum)

3) Alloy aluminum plate (composition of aluminum and other alloy material, usually alu-copper, alu-manganese, alu-silicon, alu-magnesium, and so on)

4) Composite aluminum plate or brazing plate (made by a variety of composite materials)

5) Alclad aluminum (coated aluminium sheet outside of aluminium sheet used for special purposes)

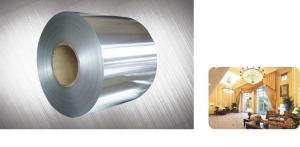

According to the thickness, it can be divided into 4 items.

1) Thin plate (aluminum sheet) 0.15-2.0mm

2) The conventional plate (aluminum sheet) 2.0-6.0mm

3) Medium plate (aluminum plate) 6.0-25.0mm

4) Thick plate (aluminum plate) 25-200mm

5) More than 200 super- thick plate

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Are aluminum sheets suitable for HVAC ductwork?

- Indeed, HVAC ductwork can be made using aluminum sheets. The lightweight and durable characteristics of aluminum make it a favored option for ductwork. Its resistance to corrosion is crucial in HVAC systems where moisture and condensation are prevalent. Moreover, aluminum ductwork exhibits excellent thermal conductivity, enabling efficient heat transfer. Furthermore, the simplicity of working with aluminum sheets renders installation and maintenance relatively easy. Ultimately, aluminum sheets guarantee dependable performance and energy efficiency, making them a trustworthy selection for HVAC ductwork.

- Q: What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary, depending on the specific alloy and temper.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- As Vincent noted, aluminium is an abundant element in the earth's crust. It occurs in all clay minerals. Its main ore, bauxite(a mixture of aluminium hydroxides) is still available in vast deposits; particularly in Australia and South America. Aluminium is a reactive element, and so is not found in nature in the elemental form. Aluminium is a metal, and an amphoteric substance; that is; it reacts with both acids and bases.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- Let me guess, making thermite? :P The easiest way by far to get aluminum I have found is breaking open an old EtchaSketch. That's aluminum powder in there. There are too many impurities on the can to make it easy, go to the dump and find some old EtchaSketches. Addition: Do NOT breathe in the powder, its not good for your system, it does large amounts of damage to your lungs, I suggest wearing a mask of some sort for safety. Do not take it lightly. Otherwise, have fun melting holes in the ground / someone's car / a safe / anything else you can get your hands on :P

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- Among them, 3003 for aluminum manganese alloy, the lowest price in the 3 series, and then 3004.3104, for aluminum, magnesium, manganese alloy than 3003 price to be slightly higherThird bit, 5 series, i.e. aluminum magnesium alloy, such as 5005.50525083. 5005 of these prices are slightly lowerThen, the ---2 system and --4 system and --7 system of the 6 series are derived

- Q: What are the potential health hazards related to working with aluminum sheets?

- <p>Working with aluminum sheets generally has low health risks. However, inhalation of aluminum dust can cause respiratory issues, such as coughing and shortness of breath. Prolonged exposure may lead to a condition known as metal fume fever. Additionally, aluminum can cause skin irritation in some individuals. It's important to use proper ventilation and personal protective equipment, such as masks and gloves, to minimize these risks.</p>

Send your message to us

Mirror Diamond Embossed Aluminum Angle Cut Sheets 3003/5005/5052/5754

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords