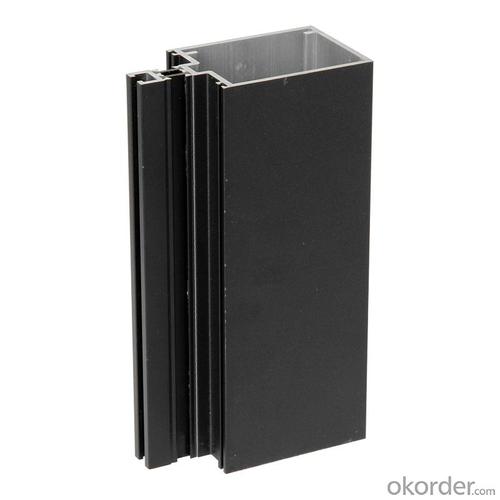

China Made Extruded Aluminum Profiles:Best Selling and Most Welcomed Colorful Anodizing Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: Are aluminum profiles suitable for swimming pool enclosures?

- Yes, aluminum profiles are suitable for swimming pool enclosures. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for outdoor applications like swimming pool enclosures. It offers strength and stability while also being low maintenance and easy to clean. Additionally, aluminum profiles can be customized to fit specific design requirements, providing a wide range of options for swimming pool enclosure construction.

- Q: This question asks if aluminum profiles can be used in outdoor settings and seeks an explanation for their suitability.

- <p>Yes, aluminum profiles can be used for outdoor applications. They are suitable for outdoor use due to their high resistance to corrosion, which is a result of the natural oxide layer that forms on aluminum when exposed to air. This layer protects the aluminum from further oxidation and damage. Additionally, aluminum profiles are lightweight, strong, and can withstand various weather conditions, making them ideal for applications such as outdoor furniture, construction, and signage. Their durability and low maintenance requirements also contribute to their popularity in outdoor settings.</p>

- Q: Are aluminum profiles suitable for constructing sustainable buildings?

- <p>Yes, aluminum profiles can be used to create sustainable building designs. They are lightweight, which reduces the energy required for transportation and construction. Aluminum is also highly recyclable, with a low energy consumption rate for recycling, making it an environmentally friendly choice. Furthermore, aluminum profiles offer excellent thermal conductivity, which can be utilized in energy-efficient designs to reduce heating and cooling costs. Their durability and resistance to corrosion contribute to the longevity of buildings, reducing the need for frequent replacements and thus lowering the environmental impact over time.</p>

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- Some of the different surface engraving or etching techniques for aluminum profiles include laser engraving, chemical etching, mechanical engraving, and sandblasting. Each technique offers unique benefits and can be used to achieve different aesthetic effects on the aluminum surface.

- Q: Explain the positive environmental impacts of utilizing recycled aluminum in the construction industry.

- <p>Using recycled aluminum in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining new bauxite, the primary source of aluminum. This reduction in mining decreases habitat destruction, water pollution, and soil erosion. Additionally, recycling aluminum saves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to lower greenhouse gas emissions and air pollution. Moreover, the use of recycled aluminum reduces landfill waste, as less material ends up in landfills. Overall, it promotes a more sustainable and eco-friendly construction process.</p>

- Q: How do aluminum profiles perform in terms of sound transmission loss?

- Aluminum profiles are known for their excellent sound transmission loss performance. Due to their dense and rigid nature, aluminum profiles effectively block and reduce the transmission of sound waves. The metal's inherent properties, such as high density and low resonance, make it an ideal material for sound insulation applications. Additionally, aluminum profiles can be designed with various shapes and thicknesses to further enhance their soundproofing capabilities. Overall, aluminum profiles offer great sound transmission loss, making them a popular choice for applications where noise reduction is desired, such as in building construction, automotive industry, and HVAC systems.

- Q: What role does glass curtain wall aluminum profile holder play?

- The subframe is formed by connecting the silicone structural adhesive with the glass and then connecting the plate with the aluminum alloy through the platen. The purpose of the subframe is to achieve the "hidden frame" purpose

- Q: Are aluminum profiles weather-resistant?

- Yes, aluminum profiles are weather-resistant. Aluminum is known for its excellent corrosion resistance and ability to withstand various weather conditions such as rain, snow, UV radiation, and extreme temperatures. This makes aluminum profiles a popular choice for outdoor applications such as windows, doors, and outdoor furniture.

- Q: What are the advantages of using aluminum profiles in the automotive aftermarket?

- Using aluminum profiles in the automotive aftermarket comes with several advantages. To begin with, aluminum profiles are both lightweight and strong, making them ideal for automotive applications. By opting for aluminum profiles instead of traditional steel or other heavy materials, vehicles can be made lighter. This results in improved fuel efficiency and reduced emissions, which is especially important in today's environmentally conscious world. Moreover, aluminum profiles provide excellent corrosion resistance. This is crucial for automotive parts that are exposed to various weather conditions and road salt. Unlike steel, aluminum does not rust, ensuring durability and longevity for aftermarket automotive components. Additionally, aluminum profiles offer great flexibility and can be easily customized and shaped to meet specific design requirements. This allows for the creation of complex and intricate designs that enhance both the aesthetics and functionality of aftermarket automotive parts. Whether it's body panels, interior trim, or structural components, aluminum profiles can be tailored effortlessly to meet the unique needs of each vehicle. Furthermore, aluminum profiles boast excellent thermal conductivity. This means they efficiently dissipate heat, making them suitable for applications such as heat exchangers or cooling systems in the automotive aftermarket. This property helps prevent overheating and ensures optimal vehicle performance. Lastly, aluminum is highly recyclable, making it a sustainable choice for the automotive aftermarket. By using aluminum profiles, manufacturers and consumers can actively contribute to reducing waste and minimizing environmental impact. Participating in the circular economy by recycling and reusing aluminum profiles helps decrease the overall carbon footprint. In conclusion, the advantages of utilizing aluminum profiles in the automotive aftermarket are evident. From weight reduction and improved fuel efficiency to corrosion resistance, customizability, thermal conductivity, and sustainability, aluminum profiles offer numerous benefits that make them an excellent choice for aftermarket automotive components.

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can vary depending on various factors such as the dimensions of the profiles, the design of the shelving system, and the quality of the aluminum used. Generally, aluminum profiles used for shelving systems can support a significant amount of weight. However, it is important to note that the weight capacity of a shelving system also depends on other components such as brackets, connectors, and the type of shelving material used (e.g., wood, glass, or metal shelves). It is recommended to consult the manufacturer or supplier of the specific aluminum profile and shelving system to obtain accurate weight capacity information. They can provide guidelines based on their product specifications, engineering calculations, and testing. Additionally, factors such as proper installation, distribution of weight, and regular maintenance also play a crucial role in ensuring the overall strength and stability of a shelving system.

Send your message to us

China Made Extruded Aluminum Profiles:Best Selling and Most Welcomed Colorful Anodizing Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords