Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Anodized Aluminum Perfile in Color RAL from China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Anodized Aluminum Perfile in Color RAL from China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Anodized Aluminum Perfile in Color RAL from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

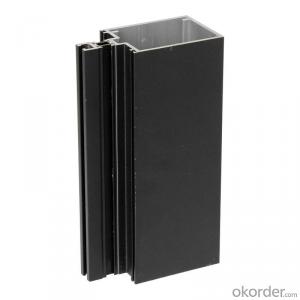

5. Image of Anodized Aluminum Perfile in Color RAL from China

6. Package and shipping of

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: What is the cost of aluminum profiles?

- Several factors can impact the cost of aluminum profiles, including the type of profile, required length and thickness, and prevailing market conditions. Typically, aluminum profiles are priced per linear foot or meter. Moreover, the price might be affected by the quality of the aluminum utilized and any necessary additional finishes or treatments. To obtain precise pricing details, it is recommended to reach out to local suppliers or manufacturers, as pricing can vary across regions.

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: This question asks for methods to preserve the look and functionality of aluminum profiles to ensure they last longer and remain in good condition.

- <p>To maintain the appearance and performance of aluminum profiles over time, follow these steps: 1. Regularly clean the profiles with a soft cloth and mild soap to remove dust and dirt. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the profiles are exposed to harsh weather conditions or chemicals. 4. Inspect the profiles periodically for signs of wear, corrosion, or damage, and repair or replace them as needed. 5. Lubricate moving parts with appropriate oils or grease to ensure smooth operation. 6. Avoid overloading the profiles or using them beyond their specified weight capacity. By following these maintenance practices, you can prolong the life and performance of aluminum profiles.</p>

- Q: Are aluminum profiles suitable for decorative applications?

- Yes, aluminum profiles are suitable for decorative applications. Aluminum is a versatile material that offers several advantages in decorative applications. Firstly, aluminum profiles can be easily shaped and formed into various designs, allowing for endless possibilities in decorative applications. They can be extruded into different shapes, sizes, and patterns, giving designers the freedom to create unique and aesthetically pleasing decorative elements. Moreover, aluminum profiles offer excellent durability and corrosion resistance, making them suitable for both indoor and outdoor decorative applications. Aluminum is known for its ability to resist rust and weathering, ensuring that decorative elements made from aluminum profiles will maintain their appearance for a long time. Additionally, aluminum profiles can be finished in various ways to enhance their decorative appeal. They can be anodized or powder-coated to add color, texture, and protection to the surface. These finishing options allow for customization and the ability to match the profiles with the overall design scheme. Furthermore, aluminum profiles are lightweight yet strong, making them easy to install and handle during the decorative application process. This characteristic also makes them suitable for applications where weight is a consideration, such as in suspended or wall-mounted decorative elements. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, and the production process of aluminum profiles requires considerably less energy compared to other materials. Choosing aluminum profiles for decorative applications aligns with sustainable design principles and contributes to reducing the environmental impact. In conclusion, aluminum profiles are highly suitable for decorative applications due to their versatility, durability, corrosion resistance, customization options, lightweight nature, and sustainability. Whether it's for interior or exterior decorative elements, aluminum profiles offer a wide range of possibilities to enhance the aesthetic appeal of any space.

- Q: Are aluminum profiles suitable for furniture applications?

- Yes, aluminum profiles are suitable for furniture applications. Aluminum is a versatile and lightweight material that offers several advantages for furniture design and construction. Firstly, aluminum profiles provide excellent strength and durability, making them ideal for furniture that needs to withstand regular use and weight-bearing. They are resistant to corrosion, which means they can be used both indoors and outdoors without the risk of rusting or deteriorating over time. Additionally, aluminum profiles offer flexibility in design. They can be easily shaped and formed into various shapes and sizes, allowing for creative and innovative furniture designs. Aluminum profiles can also be extruded into different profiles and sections, enabling customization and adaptability to different furniture styles and requirements. Furthermore, aluminum is a sustainable material that can be recycled repeatedly without losing its properties. This makes it an environmentally friendly choice for furniture applications. Overall, aluminum profiles provide a combination of strength, durability, versatility, and sustainability, making them a suitable choice for various furniture applications.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: Are aluminum profiles suitable for solar panel frames?

- Solar panel frames made from aluminum profiles are an excellent option. Aluminum is a lightweight material that is also strong, making it perfect for constructing solar panel frames. It offers exceptional resistance to corrosion, which is crucial for outdoor use, ensuring that the frames last a long time. Additionally, aluminum profiles can be easily shaped and formed, allowing for flexible and customizable designs that can accommodate various solar panel sizes and configurations. Moreover, aluminum is highly sustainable as it is completely recyclable, aligning with the environmentally-friendly nature of solar energy. In summary, using aluminum profiles for solar panel frames provides numerous benefits such as strength, durability, corrosion resistance, flexibility, and sustainability, making it an extremely suitable choice.

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- The 3. longitudinal side camber: the largest plane profile on the platform, to achieve stability by self, at the ends of the side section had draw a straight line on the platform, measuring the maximum gap between this line and the side profile values for longitudinal side camber.A: can be completely surrounded by the profile of cross-section of the smallest circle.Manual input, for reference only, specific explanation can view GB/T 14846.

- Q: How do aluminum profiles perform in terms of vibration resistance?

- Aluminum profiles exhibit excellent vibration resistance due to their inherent stiffness and high strength-to-weight ratio. The material's low density helps in dampening vibrations, while its structural integrity ensures minimal deformation or fatigue under dynamic loads. Additionally, aluminum profiles can be further enhanced with vibration-damping materials or techniques to optimize their performance in vibration-prone applications.

Send your message to us

Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords